Posted to News on 14th Feb 2014, 13:39

Eurotherm launches new precision E+PLC family

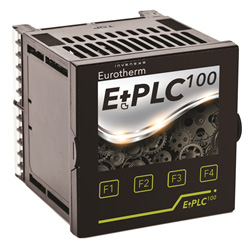

Invensys Eurotherm is launching the E+PLC family of precision PLCs that is aimed at significantly increasing the efficiency and profitability of heat treatment and thermal processing applications. The new E+PLC combines precision measurement and PID control, secure data recording and visualisation options.

Previously, to obtain optimum performance and meet accurate pyrometry specifications (eg AMS2750E), companies needed to buy separate products for temperature control, data recording and visualisation. This was costly and inefficient. Combining all these products into one easy-to-use, versatile and highly functioning precision PLC platform simplifies commissioning and reduces engineering time. The E+PLC also targets operational efficiency and is said to make regulatory compliance easier (in 'E+PLC' the E represents Eurotherm's analogue control and secure data recording, while the PLC highlights the CODESYS complete, standard IEC 61131-3 programming environment).

Tim Linnell, the Product Portfolio Manager at Invensys Eurotherm, explains how the E+PLC's versatile functionality will have a significant impact on the manufacturing industry, meeting the demanding challenges of modern processing needs: "For many companies in an increasingly competitive global environment, the efficiency of thermal treatments will be the difference between being profitable and not. Eurotherm's unique fast-reacting PID control minimises overshoot, improving accuracy and reducing waste.

"The high-precision temperature control ensures the correct temperature is obtained quicker and stays at the optimum level required without deviation, ensuring high-quality results first time without wasting time waiting for operating temperature to be reached. This increases throughput of a furnace or thermal treating machine in comparison with traditional PLC-based control. Fast-acting PID with overshoot inhibition can enable an extra furnace batch cycle to be completed within any 24-hour period. By eliminating damping of PID sets and relying on Eurotherm's unique overshoot inhibition customers can heat aggressively up to temperature with the confidence of keeping within the required setpoint temperature tolerances."

Software blocks and auto-tuning

"These benefits are easily realised in the E+PLC using standard software building blocks, with an auto-tuning function to match the control response to a particular application. This can reduce the time needed to programme and commission an application from days (and sometimes weeks) to hours.

"The E+PLC range also includes secure data logging designed to meet the requirements of thermal treatment standards such as CQI-9 and AMS2750 E. Indeed, Eurotherm has built its business over many years around the requirements of such standards, and is trusted by auditors and customers alike. Of course data logging is only one part of standards compliance, and our highly stable precision measurement circuitry assures compliance with accuracy specifications, aids conformance to System Accuracy Tests (SAT) and improves the output from Temperature Uniformity Surveys (TUS).

"Data recording and temperature control is highly specialised and Eurotherm has a track record gained over 50 years in developing these products, building a peerless reputation with the leading businesses in the thermal treatment sector. Eurotherm operate also in some of the most stringently regulated industry sectors in the world, including the global pharmaceutical and biotech industries where our products and secure data recording infrastructure are trusted implicitly.

"Combining Eurotherm's best-of-breed products and adding visualisation tools into this new self-contained precision E+PLC platform brings high efficiencies and reduced engineering time."

Key features and benefits of the E+PLC include:

- Straightforward compliance with thermal processing standards - for example, CQI-9, AMS2750 E

- Easy-to-commission precision PID control blocks with auto-tuning

- Setpoint programmer; this easy configuration saves programming time and gives guaranteed operation, thereby helping to lower processing costs

- Precision measurement of process variables to give accurate, repeatable results, which translates to minimum energy usage

- Total data integrity and secure recording, keeping valuable process records safe by using highly robust file storage strategies to protect against power and network failures

- Batch functionality and complete traceability

- An open CODESYS platform, a de facto industry standard. Using an open platform, the industry-standard (IEC 61131-3), the E+PLC is well supported through Eurotherm and an extended community of PLC programmers

- Integrated HMI software platform with a variety of visualisation options

- Flexible visualisation giving dynamic debugging of application programmes together with concurrent development of the final process visualisation

The E+PLC100 is a compact device with an integral 3.5inch touchscreen display, four analogue inputs, two digital inputs and up to two logic outputs, three relay outputs and three DC outputs. For more complex applications the E+PLC400 is a complete, modular PLC. To complement the E+PLC units, Eurotherm supplies E+HMI operator panels with a choice of 7inch and 13inch colour TFT screens. These HMIs benefit from powerful graphics capability, easy creation and automatic control strategy integration via the E+PLC programming environment. Each operator panel has two Ethernet ports and an integral switch.

Follow the link for more information about the precision E+PLC family.