Posted to News on 27th Feb 2008, 12:41

Explaining the regulatory requirement to inspect light curtains

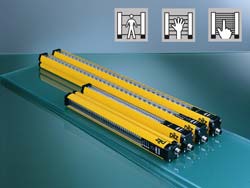

Stewart Robinson of Pilz Automation Technology explains the regulatory requirements for inspecting safety light curtains and the necessary inspection process.

Here in the UK, the Provision and Use of Work Equipment Regulations 1998 (PUWER 98) state that safety-related equipment must be inspected to ensure it is 'suitable and sufficient' for the intended purpose and that any equipment that might degrade over time should be inspected regularly. While safety light curtains may appear to be fit-and-forget devices, with no moving or contacting parts to wear, most suppliers state in their documentation that light curtains should be inspected regularly. In this context, 'regularly' is normally interpreted as 'annually'.

If a light curtain is not inspected and its performance has deteriorated, it could result in an unsafe situation arising. In extreme cases, this could lead to a major injury being sustained.

ESPE (electrosensitive protective equipment) certification involves an inspection to ensure that the light curtain cannot be defeated and that it is correctly positioned in relation to the mechanical hazards. Note that sometimes people refer to AOPD (active opto-electronic protective device) certification, which is the same as ESPE certification. A typical machine with a single safety light curtain would take about one hour to inspect and a little more time to complete the documentation. Further information about the requirements for ESPE assessments are contained in IEC 62046 (Technical Specification, Safety of machinery - Application of protective equipment to detect the presence of persons).

Inspection procedure

Inspections are relatively straightforward to perform, though the inspector must have the appropriate competence and use specialist equipment. First the height of the hazard window is checked, together with the size of the light guard and its type, to ensure the guard adequately covers the hazard window. Then a stop time performance monitor is mounted on the machine to measure accurately how long it takes for the moving parts to come to a standstill from the moment the light barrier is triggered. This figure is used to calculate the required distance between the hazard and the light guard as per BS EN 999:1999 (Safety of machinery. The positioning of protective equipment in respect of approach speeds of parts of the human body).

Next the actual distance is measured so that it can be compared with the calculated figure to ensure the light guard is mounted in the correct position. The light guard is then checked to ensure it is correctly integrated within a suitable safety-related control system.

A written report is prepared for every machine inspected. Provided all the tests are passed satisfactorily, a label is applied to the machine to show that it is certified and that it is due for inspection again in 12 months' time.

Pilz Automation Technology in the UK has Notified Body status for carrying out ESPE inspections, which is granted through the formal recognition of Pilz GmbH in Germany as an Inspection Body for this work. Five engineers in the UK have undergone the necessary training against EN ISO 17020 (General criteria for the operation of various types of bodies performing inspection) and are therefore qualified and competent to perform ESPE certifications for UK customers.

For more information about ESPE certification visit www.pilz.co.uk.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>