Posted to News on 15th Mar 2022, 08:55

ExpoPharma chooses integrated servo motion control system

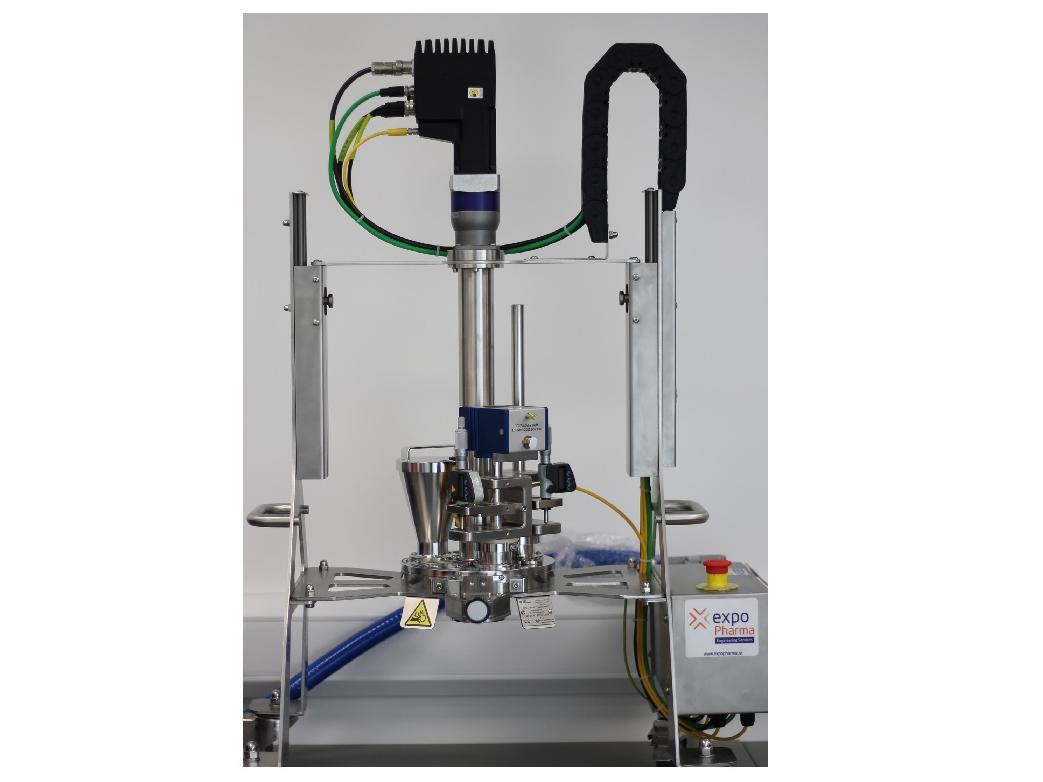

Mclennan solution expands range of benchtop PAT probe simulators

ExpoPharma Engineering Services, a part of the long-established Expo Technologies Group, provides engineered project-based products & services for a wide range of manufacturing industries. Part of its work in the pharmaceutical industry includes the design and supply of PAT (Process Analytical Technology) probe holders and sampling systems, facilitating the optimal performance of spectroscopic analysers used to evaluate critical chemical structure, size and identity of compounds during drug manufacturing processes that are now widely employed in cGMP (certified Good Quality Product) production plant.

To mitigate the cost and complexity of using full-scale cGMP manufacturing plant to optimise PAT probe compatibility, ExpoPharma has developed a series of ‘bench top’ simulators that provide real-time spectroscopic performance analysis. As a preferred motion systems supplier to ExpoPharma, Mclennan supplied a 3-axis motion control system in 2019 for a powder-stream conditioning chute used for PAT probe analysis and recently followed this with a single-axis servo motion system for a new Benchtop Feed Frame Simulator for tablet production development.

Spectroscopic environment simulated in a generic version

Simply put, ExpoPharma’s Benchtop Feed Frame Simulator simulates the spectroscopic environment in a generic version of several of the common designs of tablet press feedframes used today. A shallow sealed cylindrical housing contains a rotating spider wheel that sweeps the bottom surface to agitate the compound required for the tablet forming process whilst various spectroscopic probes under test are positioned above the fingers of the spider wheel.

The simulator can be adapted for a wide range of spectroscopic probes for Raman spectroscopy and near infrared (NIR) spectrometers, providing flexibility across various chemical signatures and characteristics of the material under evaluation. The spider wheel’s form and function can be altered during analysis with different wheel diameters, number of fingers, and shape of fingers (curved, straight, varying height, notches, and grooves etc.).

Mclennan’s single axis motion system drives the spider wheel, precisely controlling the rotation speed and torque, which are also variables in the process. The housing includes both inlet and outlet ports allowing the material to flow through and simulate the real-time environment of a tablet press. In this way the spectroscopy probe(s) analysis is optimised. This automated process, which involves just a few grams of material under test, both speeds and simplifies the spectrometer evaluation and when compared to directly employing cGMP equipment also removes the need for the often substantial and costly modification of the machinery.

This saves significant cost and development timescales for new drug manufacture and well as support quality and performance refinements for existing tablet production. The cGMP plant also benefits from increased production availability.

ExpoPharma engineering team’s confidence in Mclennan

McLennan’s single axis motion system utilises the same Modbus TCP/IP over Ethernet communications architecture and interfaced HMI set-up as the 3-axis system previously supplied for the powder-stream conditioning chute simulator. This familiarity and the success of the previous project helped secure the ExpoPharma engineering team’s confidence in Mclennan.

The main drive is a MAC 400 series integrated servomotor from the Danish motion components specialist, JVL – a valued Mclennan distribution partner. This all-in-one motion solution comprises a powerful servomotor and drive with a motion controller plus I/O and comms in a single durable housing. This unit is fitted with an NPS Alpha Value series planetary gear unit from Wittenstein – another of Mclennan’s distribution partners. This combination, with a 30:1 gear reduction ratio, ensures precise speed and torque control through optimal inertia matching for the spider wheel payload.

Both the integrated servo motor and the planetary gear unit meet the IP65 minimum specification requirement set by ExpoPharma. This compact, distributed motor technology allows all of the motion components to be locally installed on the simulator’s support framework without the need for a separate control cabinet – keeping machine wiring to a minimum and maintaining the portability pf the equipment, as well as minimising any potential for electrical noise that might interfere with the spectroscopy probe electronics.

Modbus TCP bus interface

The motion system includes a Modbus TCP bus interface - one of several comm’s options available for the MAC 400 series integrated servomotor – and is configured as a network segment with a GH070E series HMI from Kinco.

Mclennan supplied this sub-system with pre-programmed motion and I/O sequences in the motion controller and graphical screens for the HMI that allow manual input of jog and operational speed, rotation direction and torque output, while displaying status of safety interlocks, alarms and emergency stops etc. With the HMI configured as a Modbus TCP sub-network master, the overall system is PC controlled via ExpoPharma’s ProaXesS software.

Unit 1, The Royston Centre

Lynchford Road

GU12 5PQ

UNITED KINGDOM

+44 (0) 1252 531444