Posted to News on 9th Jul 2014, 16:41

Extrusion processes and terminology white paper

A new white paper sheds light on the extrusion processes and terminology used for the benefit of specifiers looking for standard or custom extruded profiles. The whitepaper can be downloaded from www.emkablog.co.uk/extrusionprocesses.

Synthetic rubber is a common material used in virtually every industrial application and available in a wide range of possible compounds. Its versatility, resilience and dynamic properties make it a particularly effective choice for applications involving shock absorption, sealing and fluid transportation.

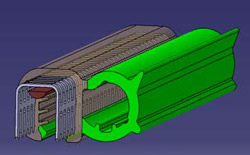

Extrusion is used to manufacture products in continuous lengths with a uniform cross-section. This section can be quite simple, i.e. circular, annular, rectangular profiles, or very complex (window profile, rubber car seal). Solid pellets or compound strips are feed through the feed hopper. The solid material is conveyed by a single, or several, rotating screws in a closed barrel. The friction from the interface between the flowing compound and the wall increases the temperature through a viscous heating process, locally melting the material. After the compound has melted and has completed its flow around the screw(s), the masticated compound enters the die. It is the job of the die to convert the cylindrical flow from the extruder into the required, sometimes quite complex, cross section.

The rubber then emerges from the extruder in a profile resembling the die shape (the design of such dies can be complicated and difficult). Traditionally, dies are designed using an expensive trial and error procedure, with possibly several trials and modifications. The main reason for this lengthy design process is that the flow patterns inside the dies are unknown. As die design possibilities remain nearly limitless, so does the number of possible extruded rubber profiles.

After being extruded, the material is cured/vulcanised using various methods that can include salt bath, autoclave, convection, hot air, ballotini and microwave.

Some common materials used in rubber extrusion include EPDM, SBR, (CR - Neoprene), Silicone, (NBR - Nitrile), and (NR- Natural rubber). Some important considerations when thinking about rubber extrusions are whether the physical and mechanical properties of the desired material are appropriate for the environment in which it will be used. Such properties as tensile strength, hardness, ageing, flexibility, permeability, and speed of recovery from deflection will vary in different materials, and need to be weighed against the benefits and weaknesses that will result from using such materials.

The biggest competitor to these materials is thermoplastic plastic which has an advantage as specific colours are easily available. Both materials continue to remain popular in many industries; however the formation of dioxins during combustion is an extreme disadvantage for thermoplastic such as PVC.

Types of extrusion

- Co-extrusion is a variation of the basic extrusion process, where two separate extruders connect to a single die and two or more separate batches of rubber are mixed by separate screws, and then fed into the die at the same time. This allows for convergence of rubber materials that contain different properties like colour and consistency.

- Cold feed extrusion involves performing the extrusion process without pre-heating. This is best suited to produce profiles, hoses, cable and sheaths. Hot feed extrusion involves pre-heating the rubber material before performing the extrusion process.

- Pin barrel extruders have a special design with many pins protruding from the cylinder wall toward the screw's centre that enhance the mixing and dispersing of the rubber as it is kneaded between the screws and the cylinder. This method can be applied to many rubber compound formulations for diverse applications.

- Vented extruders have screws of an original and unique design. This type is easy to maintain and occupies very little floor space.

Further information on the extrusion processes and terminology white paper, plus EMKA products and services may be found at www.emka.co.uk.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>