Posted to News on 29th Oct 2020, 08:58

Factors to consider when specifying brakes for theatre and stage applications

Avoiding drama in a theatre seems like an odd thing to be doing, but KEB specialises in it. The company has been supplying spring-applied brakes for the theatre and stage industry for more than 40 years. From deck winches and turntables to line shaft hoists and orchestra lifts, a range of factors should be considered when specifying brakes says KEB Automation's Jonathan Bullick.

There are many factors to consider when specifying brakes for theatre and stage machinery such as hoists, lifting equipment and winches. These factors include safety, noise levels, hand releases, microswitches, double brakes, load brakes and double interposed brakes.

Safety

Typically for theatre and stage equipment, a power-off failsafe brake is desired, particularly if the application is a hoist lifting an overhead load. Some theatres have been known to install large permanent magnet (PM) servo motors for the hoisting axes, with the motors equipped with PM brakes. While PM brakes do provide power-off brake engagement, they are not ‘failsafe’ because if the air gap becomes too large through wear or misadjustment, the brakes can fail open and unsafely.

Electrically released spring applied brakes are more suitable, as they use multiple springs embedded in the magnet housing to provide failsafe power-off braking. For this reason, KEB offers spring-set brake designs for servo motors if needed. As drives are usually used in these applications, spring applied brakes can be rated for holding torques, typically giving 50% more torque for the same size of brake.

Noise reduction

If a theatre hoist or winch operates during a performance, the machine and all of its components should generate as little noise as possible.This is normally not a problem for small brakes, but becomes more challenging when using larger brakes. Large DC spring-set brakes have an armature that actuates back and forth, making metal-to-metal contact with the magnet housing. The noise can be significant and becomes more noticeable the larger the brake and the larger the moving armature mass.

Several design features can be employed in brakes which dampen the actuation noise. Our own theatre brakes, for example, as standard are designed to produce less than 65dB noise measured at a distance of 1 metre. In practice, these brakes are even quieter. Typically, other automation components in the machine application such as motor contactors and gearing produce more noise than our brakes do.

Hand release

A manual hand release allows the brake to be released without electrical power. This can be very useful for diagnostics and machine commissioning. For some theatre applications such as when a performer flies across the stage, a hand release is absolutely required and is not an option. In the case of a loss of power, a performer must be able to be lowered rather than hanging indefinitely in the air.

Microswitch

A microswitch provides engagement feedback of the brake state. It is always a good idea to use a microswitch to give extra peace of mind, particularly when flying performers or applications that move very large loads such as speaker clusters or orchestra pits.

A microswitch on the brake will certainly add extra cost to the brake so the requirements of the application must be taken into account. It should also be noted that some external control is needed to evaluate the microswitch signal. This typically takes the form of a VFD or PLC. Our own microswitches can be configured for either NO or NC configurations.

Double brake

Redundant braking is often preferred or required in theatre and stage machines. There are a number of different ways to achieve this and the geography of the installation often dictates the brake placement and machine design.

For applications that require two brakes on the high speed motor side, KEB’s D8 spring-set brake can be used. The D8 double brake is basically two brakes with independent electrical and magnetic circuits. Each brake is controlled and powered separately and is capable of stopping and holding the rated load by itself. The D8 design is very compact and the brakes ship from the factory with pre-set air gaps so the installation is straightforward. Options such as hand releases and microswitches can still be implemented.

Load brakes

One alternative to using a double brake on the motor side would be to place one brake on the output (gearbox) side of the machine in addition to the gearmotor brake. This output brake is typically referred to as a load brake or parking brake.

Philosophically, there are some advantages to having a brake acting directly on the drum shaft. A user can be assured that the brake is acting on the drum shaft and does not have intermediate links or couplings inbetween.

Interposed brakes

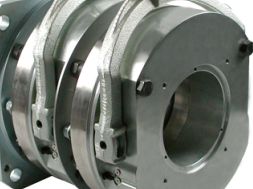

It is also worth considering interposed brakes. These brakes are spring-set and electrically released. The spring-set brake is packaged in a double C-Face housing that has an input sleeve and output shaft with common standard dimensions. These brakes are popular in theatre applications because they are modular and easy to install. It allows a brake to be easily added in the middle of an off-the-shelf motor and gearbox and can be mounted horizontally or vertically.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>