Posted to News on 14th Feb 2008, 16:17

FactoryTalk Historian Site Edition gathers plant floor data

To help manufacturers optimise production processes through the analysis of historical plant-floor data, Rockwell Automation is releasing the FactoryTalk Historian Site Edition (SE). The new software application helps manufacturers automatically identify, gather and configure high-speed detailed data from any control system or human-machine interface (HMI) software. Through sophisticated data analysis and reporting capabilities, manufacturers can then use these data to gain greater insight into production operations.

When using historian software applications, manufacturers traditionally need to go to each individual system on the plant floor to manually identify the data points used to gather production information. In some cases, this may include several thousand data points that would then need to be reviewed, approved and configured with the historian application - a potentially error-prone process that can often take weeks to complete. FactoryTalk Historian SE automatically discovers all controllers and HMI devices in the plant and their associated data points. This information is presented to the user, who can review and approve the data that can then be configured by FactoryTalk Historian SE in a matter of hours.

FactoryTalk Historian builds on industry-leading technology licensed from OSIsoft and deploys the FactoryTalk Services Platform for premier integration with the Rockwell Automation Integrated Architecture. Rockwell Automation has based the design of FactoryTalk Historian on a distributed, tiered architecture that enables employees in different locations and at different operating levels to view and analyse historical data from their unique perspectives. Operators, for example, can view data from the actual machine they are using, while plant-level supervisors can view individual machines or complete lines in real time to build comparisons against standards and assess how batches and critical processes are performing. Meanwhile, senior management can use the same technology to develop executive dashboards that compare key performance indicators (KPIs) of production activity across multiple locations.

Kevin Roach, vice president of software for Rockwell Automation, says: "Our long-term FactoryTalk Historian strategy is designed to help ensure that organisations can access the right data at the right time, at any level of operation. Manufacturers can facilitate the information flow by tightly integrating historian capability at the device level and incorporating aspects of historian functionality into other relevant plant information applications. Doing so increases the breadth, depth and accuracy of available data."

How FactoryTalk Historian SE works

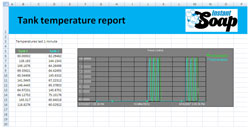

FactoryTalk Historian SE collects, stores, analyses and visualises production data through powerful data capture and storage engines, which can be used within process, discrete and hybrid environments. It also utilises a variety of reporting tools such as time-series trends, bar charts, pie charts and tabular trends to enable an easy method for generating reports using Microsoft Excel. FactoryTalk Historian SE uses compressed storage data algorithms to contain vast amounts of data in small storage formats so that users can retrieve data quickly over short or long time spans. The time-series data can then be used as a basis for various analytical activities throughout the plant to support continuous improvement and help decrease overhead costs by improving the efficiency of data collection and reporting.

Two new tools within FactoryTalk Historian are DataLink and ProcessBook. Both tools display real time or historical data to help manufacturers gather and monitor data from the plant floor. FactoryTalk Historian DataLink provides a live link between the FactoryTalk Historian database and Microsoft Excel to help users access real time or historical data more quickly from the application in the familiar graphical format of a spreadsheet. The FactoryTalk Historian ProcessBook helps manufacturers build collections of 'display entries' that show data from one historical system or more including static and dynamic information from outside sources such as trends, schematic drawings, laboratory data or specifications.