Posted to News on 7th Oct 2021, 08:58

‘First condition monitoring solution' for monorail guidance systems

Schaeffler DuraSense signals lower production costs for machinery manufacturers

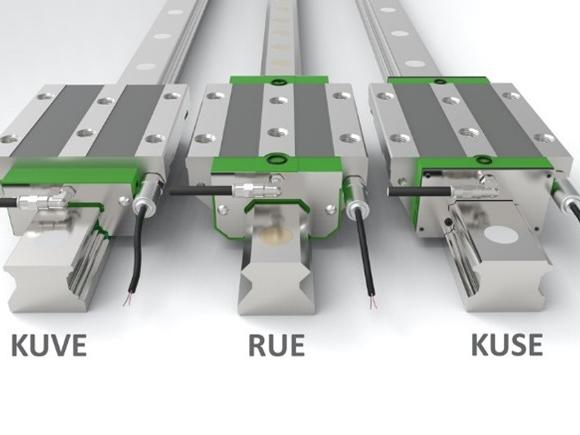

Schaeffler DuraSense is said to be the world’s first condition monitoring solution for monorail guidance systems. DuraSense is an optional add-on that claims many benefits, including lower production costs for machinery manufacturers, and lower operating costs and increased uptime for machine owners.

“For example, it can be used to monitor and evaluate manual relubrication, providing a cost-effective alternative to installing an expensive central lubrication system," Schaeffler points out. "In set-ups where a central lubrication system is installed, DuraSense can be used for the early detection of all types of faults that can lead to insufficient or inadequate lubrication, thereby preventing both lubricant starvation and excessive lubrication.

"Decreasing intervals between lubrication runs are a sign of wear and may indicate that the components in question are nearing the end of their operating life. Schaeffler DuraSense ensures that lubrication is delivered only as and when required, reducing lubricant consumption by up to 30%.”

This offers major benefits, particularly in machines that use cooling lubricants, as it significantly reduces downstream oil separation costs.

Costly repairs and delays avoided

“Factory floor applications show that DuraSense can also reliably detect installation faults and carriage installation damage, even before the plant is commissioned,” adds Schaeffler. “This means DuraSense can spare manufacturers costly repairs and delays when commissioning machines in their clients’ factories.”

Plans for additional functionality include the ability to use DuraSense data outputs to detect various types of damage to linear guideways, such as pitting and damage caused by foreign objects.

User interface to raw data

In addition to the above core functions, Schaeffler is now providing an interface that its customers can use to access raw data from the DuraSense system’s vibration sensors. This functionality comes in response to customer demand, with many manufacturers keen to harness the DuraSense system’s potential as a machine condition monitoring tool.

One such customer is Andritz Kaiser, a leading manufacturer of automatic stamping presses. Its head of product development, Paolo Matassoni, gives the following assessment: “The sensors are perfectly positioned for data-driven analysis of machine condition, because they are located right at the interface between static and moving parts. We use DuraSense in our latest-model machine, the Top Line 2000. All we have to do now is convert the captured data into human-readable language.”

Schaeffler DuraSense as retrofit kit

Schaeffler is now also offering a DuraSense retrofit kit for the countless legacy plants and machines currently in use in the manufacturing industry. When it comes time to swap out carriages in their systems, customers will receive replacements with integrated sensors. However, carriages that are low-use and therefore do not need replacement can be upgraded by installing sensors using the new retrofit kit. This kit is also the ideal option for users wanting to try out the DuraSense system and learn how it works.

There is still plenty of time to visit Schaeffler at EMO MILANO 2021 in Hall 3, Stand E47. The show runs from 4- 9 October 2021.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>