Posted to News on 19th Sep 2008, 11:12

Flexible link chain conveyor saves time and cost

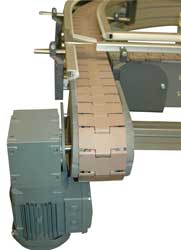

MiniTec UK is launching a new flexible link chain conveyor system aimed at processing and materials handling applications in the food, cosmetics and pharmaceutical industries. The GFK90 is fully compatible with the MiniTec Profile System machine framing range, allowing complete conveying and product handling systems to be designed and built using components from one supplier - resulting in savings in both time and costs.

The GFK90 conveyor is based upon 82.5mm wide chain segments that are interlinked with a minimal gap that allows very small components to be transported. In addition, this configurations provides for god flexibility through horizontal and vertical bends; a 500mm horizontal radius capability ensures that conveyor systems require minimal floor space.

Customers can specify plastic or stainless steel conveyor segments to suit various components or materials being transported. Plastic segments are suited to ambient temperatures from -20 to +60degC; the stainless steel option suits temperatures up to 120degC.

To adapt to the customer's conveying requirements, the GFK90's chain segments may also be customised: flat-form plastic or stainless steel chain segments may include machined features to assist transport of components; integral rollers can be added to reduce friction and counter product accumulation; rubber or other materials may be added to aid friction for inclined sections.

Speeds and loads

Depending on the components being conveyed, the conveyor path, and the type of chain material selected, speeds of up to 50m/min are possible. Conveyor loading, which is also material dependant, is up to 2000N.

The GFK90 conveyor system is based on MiniTec's 45mm profile with two vertically oriented T-slots that accept standard interlocking fixtures and fittings from the Profile System machine building range. The upper slot is typically used to locate sensors, side rails, panels and guards. The lower slot is used for mounting brackets, motors and machine frame substructures. All connection bolts supplied are made of corrosion-resistant stainless steel and a wide choice of conveyor drives is available, including inverters for variable-speed conveying.

As with all MiniTec products, comprehensive CAD data and design software is available to help visualise and select system elements; MiniTec UK can also provide a design service with on-site assembly and commissioning if required.

Unit 1 Telford Road

Houndmills Industrial Estate

RG21 6YU

UNITED KINGDOM

+44 (0)1256 365605