Posted to News on 29th Nov 2023, 15:00

Flexible, precise guidance solution for higher payloads

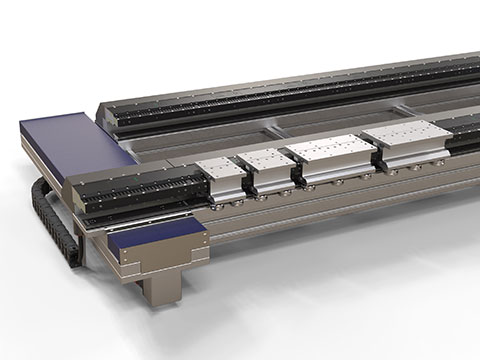

Responding to market demand for higher load, HepcoMotion is expanding its range of guidance solutions for Beckhoff’s XTS with the new GFX-r – a system providing movement in rectangular paths. Based on the existing GFX design and incorporating the inherent flexibility and precision of GFX/XTS technology, the curved segments have been removed, enabling transportation of payloads up to 40kg.

In the past decade, HepcoMotion and Beckhoff have forged a strong relationship, yielding the market-leading linear SCT (Smart Conveyor Technology) product in the form of GFX/XTS. In that time, there has been a major uptake of SCT.

As early adopters have seen significant benefits in performance, service life, capabilities, and flexibility, GFX/XTS has become their go-to product for Smart Conveyor Technology for many industries including pharmaceutical, food handling and processing, mid-line and end-of-line packaging, EV battery assembly and handling, inspection, and product sorting operations. With thousands of metres of GFX/XTS out in the market, working year-in, year-out, industry confidence in the product is very high.

Incredibly flexible, the Beckhoff XTS drive uses unique linear motor technology to independently drive and control movers around a track, enabling the seamless combination of work processes of varying durations, on the fly product changes, and the addition or removal of workstations as needed. Hepco’s GFX serves as the transport path, mechanically guiding the movers along the motor modules. It absorbs the substantial forces acting on the movers, ensuring precise alignment and resistance to deflection with great precision.

GFX-r is the integration of Beckhoff and Hepco’s TMS (Track Management System) and the increased drive capacity of XTS 7 and 10 pole magnet arrays. By removing the curved sections, a larger mover, powered by Beckhoff's longer magnet arrays can be used. TMS completes the rectangular path, transitioning movers between tracks.

Increased payload capacity

With an impressive load-bearing capability, GFX-r is ready to make a significant impact across many industries including automotive and EV, aerospace and logistics. GFX-r is ideally suited for machine cells incorporating robots, power tools and sensors, as well as for automated assembly and inspection systems. The possibilities are endless; indeed, any application with loads up to 40kg, significant moment loads, and heightened in-process stresses, stands to gain immensely.

The absence of curved motor sections allows movers to be stronger, more powerful and with a larger mounting platform, while maintaining accuracy, durability, and agility. Mover speeds of 4m/s, payloads up to 40kg and press loads up to 1500N are possible. Additionally, movers with longer magnet arrays also reduce heating losses by up to 60%. GFX-r is available in both 4- and 6-bearing versions for increased strength and stability.

GFX-r utilises the existing parts and expertise that have made GFX/XTS, the industry-leading solution including GFX-PRT2 straight slide hardware, base plates, and motor brackets, as well as Beckhoff’s XTS motors and TwinCAT system. GFX-r offers repeatability of 10µm, even when carrying a 30kg payload at a speed of 3m/s.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>