Posted to News on 14th Mar 2022, 08:55

‘Fleximatisation’ – the new byword for flexibility and automation

Why variation is the key partnership goal for Lenze and machine builder TechNikkels

In this article, Lenze and machine builder TechNikkels talk abut their enduring partnership and how flexible automation is driving the success of their collaboration

At TechNikkels, its motto is 'fleximatise'. Automation, but flexible. The company develops and builds machines for feeding, filling and sealing bottles, jars and (jerry)cans and American folding boxes – specifically for companies that process a wide variety of them. Partner for their automation needs is Lenze.

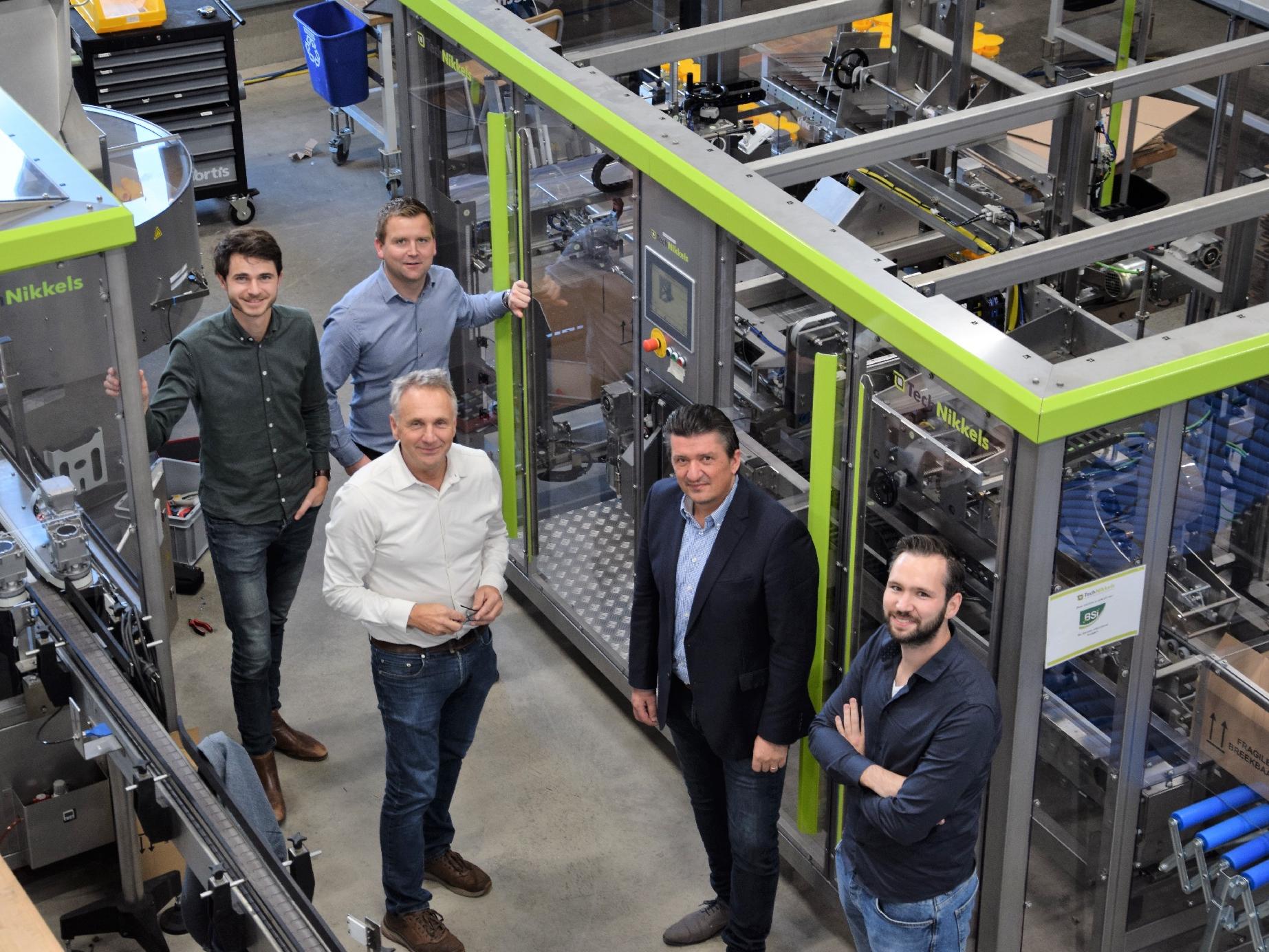

"With Lenze, we have taken a really big step," says Thijs Krijgsman, manager sales and services. At the table are also Daan Nikkels, responsible for service business development and on behalf of Lenze Stefan van Dooren and Marc Vissers. "We are now six or seven years ago since we went into business with Lenze and that to full satisfaction," continues Krijgsman. When the coffee is served, director and founder Henk Nikkels sits down. In the background, he is working with the team on developments for the future.

Fully committed to servitisation

Nikkels earned his spurs in the special machinery sector at a few large industrial companies. He started the company in 2003 and in 2011 began developing his own filling and packaging line. By now, the company is a mature one and is fully committed to servitisation. "Customers ask for service and that means attention to their needs. Whereas the focus used to be mainly on building high-quality flexible machines, it has now been expanded to ensure that customers get the maximum yield from our machines. One of our goals is to build long-term relationships with customers by proactively helping them to optimise their production results. And because we operate locally, particularly in the Netherlands and Belgium, we can also respond very quickly to requests.

“Today, we prefer to do this remotely, of course, but, if necessary, we can be on location quickly. In five years' time, things may look completely different and we may be able to serve new markets more easily, because we will have further developed remote support with all the available tools. We're not yet using the full potential of that."

Important role as a machine builder

It is difficult for many companies to staff their technical services properly. On the one hand, because of a trend towards reduced availability of technicians and, on the other, because of the increased complexity of machines. Because in most filling and packaging lines, you see machines from different manufacturers. Each one has its own way of controlling, operating and using components. And even in one machine, you are of course dealing with components from different suppliers. Nikkels sees an important role for his company here:

"As a machine builder, we really make the difference. We build complete lines ourselves, including our own controls. And there is more to it than there used to be; a number of our HBO-WTB graduates have become fully-fledged software engineers."

Different operations

TechNikkels' machines fully automate several operations in a packaging process. Think of feeding the packs, filling them, closing them and packing them into a box. During the tour, we see a few challenges. "Not only the shape and size of a packaging can be very diverse, but also the material used and the margins on the thickness of that material. Packaging is becoming thinner for cost reasons. And that sometimes has consequences for how easy it is to process products", explains Krijgsman.

"Tests are being conducted with a transparent plastic bottle that is processed on a machine at high speed. "We don't just want to deliver a machine or a line, but also an optimal performance of that machine and a smaller CO2 footprint. This means that we also advise and develop proactively in the area of monitoring."

"Also at Lenze, we see these developments taking shape more and more in the market", adds project manager Stefan van Dooren. "How do you stay competitive without becoming a price fighter? You find a distinguishing factor in the life cycle of the machine. Helping customers to get the most out of the machine – ie, optimal use over its entire life cycle. But because machine builders are often mechanically oriented, they don't have all the IT knowledge themselves to build something from scratch. That's where Lenze products can make a big contribution. We see that the visions and organisations of Lenze and TechNikkels fit together seamlessly and we have several pilot projects running."

Efficiency is key

Krijgsman: "It is indeed increasingly about getting more return from the packaging line. So, it's not about shopping around for the cheapest individual machine or components, but companies looking for a line with an optimal return. And industry 4.0 and digitalisation can support this. One example is the creation of dashboards for OEE improvement. We have a lot of data at our disposal with which we have input for further development and optimisation."

"Many of our customers are also active in the field of OEE themselves. They are very satisfied with the approach. The data that comes out of the machine is purely factual. This allows you to analyse the production and see exactly where you can improve. You substantiate your OEE, as it were, with objective data. Because the goal is not to tell them how to do it, but to provide tools to focus on the right things.

Partners

Also at Lenze, it sees the advantage of working with your supplier. Marc Vissers: "That cooperation is much closer with the result that you no longer have a customer/supplier relationship, but really become partners. Then everyone feels responsible and that results in higher commitment."

Henk nods in agreement: "Customers are busy with their business, the front end so to speak. We deal with the back end of their business and Lenze deals with the back end of our business. The vision of partnership is supported throughout the organisation, everything is aimed at helping the customer quickly by responding as flexibly as possible.

“You can be much more focused and often you can even help remotely. We want to be close to our customers, which is why we are now working on a pilot for a portal where questions are received in a standard way. We can unburden the customer as much as possible and identify and analyse trends quickly and easily. I am glad that we are working on this, because it is very productive, both for the customer and for development. You create learning capacity about the questions from the field and the associated causes."

Flexibility production

The flexibility of TechNikkels is not only expressed in the types of packaging a machine can process, but also in its use. Operating, adjusting, controlling, flexible use of components: everything is aimed at flexible production. One of the machines we see has a storage area for the format parts, so that they can be changed over to another product as quickly as possible, it states.

"Our machines are specially designed for a wide product range, that is our distinguishing factor", says Thijs. "That's why all our machines are super fast or even fully automatic changeover machines. Nowadays, batches are often small and product life cycles short. Being able to change quickly and easily without errors is a real must. Everything is aimed at making the line easy to operate, also with a view to staff turnover - in fact, anyone can operate this machine."

Nikkels explains that "everything in the machine is aimed at variation. We choose the right technology for each process, such as when placing bottles in the box. If you use grippers, then your grippers have to be very cleverly engineered. If you reverse the process and lower the bottles into the box onto a tray and then fold the box closed from below, then only the size of the box is decisive. Compared to expensive grippers, you then only need simple plate components to handle all the different sizes. We try to use as many components as possible from a single source so that everything is coordinated in the basic stages."

Support and condition monitoring

For the remote provision of support and condition monitoring, the PLC assumes the role of the gateway to the outside world, as it were. The PLC becomes an actuator and communicator. van Dooren: "All data is displayed in a dashboard. That gives real added value, because everything is coordinated, it really is an end-to-end solution. And with the dashboard you have a great tool for OEE monitoring."

Nikkels explains that a customer wanted to buy their own software system for this. "Until they saw that our machines already offered that. So now they have asked us to create data points on their other machines as well." Krijgsman adds: "Showing figures is not the art. Information and context are important. Customers want dashboards that are as simple as possible, that offer the information in a clear way and that everyone can read. We ask the client what information is important and build a clear dashboard, based on the wishes of the client, with objective information. A production manager can use that.

Nikkels sees even more opportunities: "The HMI can be a distinguishing factor for the operator's job satisfaction. We design our HMI to be very user-friendly; we say, 'for the operator's smile'. But for us it is important that we can achieve less downtime, because we can watch the operator remotely. That way, you can offer support very quickly in the event of a stoppage."

Maximum support

Another example passes in review. In 2014, TechNikkels built a large special machine for wrapping gift paper. And at the same time, the company already had an order underway for a large line with all kinds of different machines. "Then it became a question of operating smartly. Because both orders had a very short lead time, and you can't just pull out all the stops. For the controls of those two orders we contacted Lenze. And we found each other immediately. We got the maximum support to get those two projects through in the desired time. This was quite early in our co-operation and I must say, we are very happy with Lenze as a partner. Both in the field of automation and in the field of operational technology. We have done quite a few projects together in the meantime and we are very satisfied."

Marc Vissers notes that the company also really has a forerunner position, when it comes to industry 4.0, which van Dooren sees as a result of the short lines of communication between sales and technology. "You see this in large companies as well, where they often focus on service as a growth strategy. But embracing it and rolling it out only works if the whole organisation is behind it." Nikkels nods: "That's right, we stand behind our strategy together. We see better support for clients through servitisation as a great opportunity to build better relationships with our clients. Of course, we also want to grow, but in a controlled way.

Management of the installed base

That overall equipment efficiency, that's all right. But asset management is also a subject that benefits from objective data and information. "If you can follow the installed base well, you can build in learning capacity with a history of questions and incidents. All inspections are transparent, in short the entire history of your installations. We are now carrying out a pilot with Lenze, in which customers send us all their questions in one portal. It is already very accessible, but it only works if the customer also embraces the new solution."

van Dooren is project leader on behalf of Lenze at the pilot: "We have a platform where everything revolves around the machine. Everything around it is included in a portal. From there we can offer remote maintenance and we log all information about such failures, but also all documentation is stored there. Everything is centralised with an extensive historical overview. We can see exactly how many and what kind of questions the customer has asked and how much remote service has been provided. Also useful for contract monitoring," he laughs. "This is now a pilot that we are running together and we are optimising it even further. We design everything to be as accessible as possible and also want to make it as easy as possible for the operator."

The developments are moving at full speed. Nikkels: "Automation will become increasingly important. Not just to save costs, but out of pure necessity, because you have to be able to work with fewer people on a line. There is a scarcity of people, resources and materials, so it's great if your supplier is close by - that's a real advantage."

And TechNickels concludes: "Our customers are busy making their packaging process more flexible, in order to improve their production results. For and with these customers, we develop quick-switch machines that are easy to operate and suitable for a wide range of packaging and formats.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>