Posted to News on 31st Aug 2021, 09:05

FLOWave success flows on

Brkert supports expansion of ultrapure water system for healthcare diagnostics

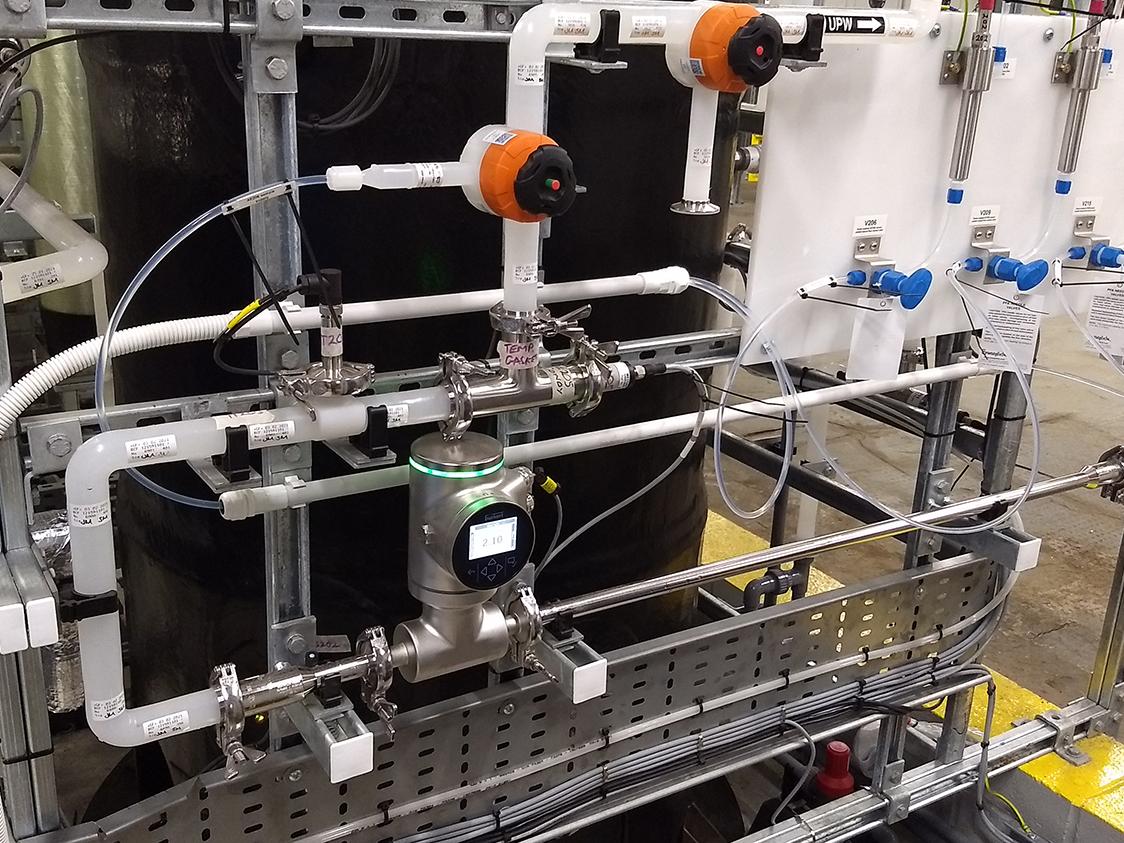

The pharmaceutical industry is embracing new technology that can reduce costs and simplify installation. At the production site of a multinational healthcare diagnostic test manufacturer, Bürkert’s FLOWave has proven to offer the best solution for measuring the flow of ultrapure water. In fact, a recent expansion project has placed a repeat order for the versatile flowmeter, having provided four years of faultless service in the initial installation.

Pharmaceutical manufacturing requires many stringent specifications to be met by all the components used in a production facility. Not least among these are hygiene and accuracy, but, when dealing with ultrapure water, the choices for a precision flowmeter can be limited. The main reason is that this liquid has very low conductivity, which rules out mag-flow meters, and until recently, there was only one viable option for a flowmeter.

Pharmaceutical advantages

Using Surface Acoustic Wave (SAW) technology, Bürkert has developed a flowmeter in which none of the components is in direct contact with the fluid and which causes no restriction to flow. Furthermore, the internal surface of the tube can be manufactured to the same surface finish as the rest of the pipeline, meaning that, in terms of hygiene, cleaning and flow conditions, there is no difference to any other piece of straight pipe within the process.

The FLOWave is also said to solve many of the issues associated with some high-end flowmeters, such as system vibration in the plant, magnetic and electrical effects, as well as the conductivity of the liquid - none of these factors has any effect on the accuracy or reliability of the flow measurements.

One of the early adoptions of the FLOWave in a pharmaceutical setting was in the healthcare diagnostics manufacturing plant, where it was used to measure ultrapure water volumes being used by a set of laboratories. The project included the installation of two FLOWaves as part of a new process build, which benefited from the compact, precision-made and cost-effective solution.

Production expansion

The recent Covid pandemic has led to increased demand for laboratory diagnostic products and the decision to install a second production line that will manufacture a key component used in Covid diagnostic testing. Part of this project was awarded to KJB Water & Process Engineering, which has been responsible for the overall design of the ultrapure water system.

Within each laboratory, there are take-off points for ultrapure water, which is supplied by a ring-main. In order to ensure sufficient volumes of ultrapure water, the flowmeters are installed on the supply and return legs of the ring main; the calculated difference in flows enables the ultrapure water production system to match demand.

Dr Corby Lee, technical consultant at KJB Water & Process Engineering, put together the supporting evidence, with backing from Bürkert, to show that the FLOWave would meet all the required specifications and be more cost effective. This demonstrated that the innovative solution could provide the required data in a hygienic setting, without the drawbacks associated with more traditional instruments.

Continued performance

As Lee explains: “Now, having selected the Bürkert product for flow measurement four years previous, the latest project to install a second production line will include two more FLOWave components. Since the initial project, the customer has had no issues with the performance of the flowmeters and we were confident this latest installation would offer the same reliability.”

According to Bürkert: “The features of FLOWave continue to lead the market, even against more recent developments to reduce the cost of the more traditional instruments, which were considered as part of the component analysis for the project. Thanks to Bürkert’s involvement in the project, as well as excellent lead times for all the parts necessary for the installation, the FLOWave met all the project requirements and was selected again.”

Lee concludes: “In terms of installation, the process is significantly less complicated when using a FLOWave device, as it can be mounted in any orientation, and its compact design makes it easy to integrate into the overall design of the plant. Furthermore, the connectivity makes the control integration very easy and, with Bürkert’s support, we were able to meet the tight delivery deadlines that were set for this project.”

Fluid Control Centre

1 Bridge End

GL7 1QY

UNITED KINGDOM

+44 (0)1285 648720