Posted to News on 29th Jan 2019, 12:26

Freight logistics look for replicable material flow systems

When the new cargo terminal starts operating at Helsinki-Vantaa Airport in early 2018, Finnair, Finland's largest carrier and one of the leading airlines in Europe-Asia traffic, will be expanding its role as an air cargo carrier in the Nordic region. Finnair has decisively chartered a course to this end by investing in 19 Airbus A350 aircraft, 11 of which have already been delivered. The investments on the ground and in the air are laying the groundwork for the expansion of passenger and freight business, in particular for European and inter-continental destinations. The complete material flow is being provided by Ldige Systems GmbH, Warburg, and the drive technology by Lenze.

Process speed and reliability are among the decisive factors contributing to the success of an intralogistical air freight system. Since 1975, Ldige has been implementing air freight systems of all magnitudes around the world. The portfolio of services ranges from consultation and system planning through to commissioning and the future servicing of air freight systems. The global reputation of the material flow experts is based on decades of experience in the air freight sector - with the aim of planning efficient and coherent logistics concepts in close collaboration with the customer and implementing them whilst taking local requirements. This generally means that highly efficient freight handling can only be achieved using the right combination of stationary and mobile materials handling technology.

Modular systems and optimised processes

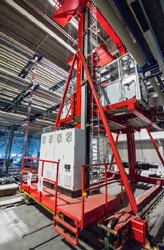

Combined mechanical and manual systems with varying degrees of automation are optimally tailored to the process of handling standard cargo units. Modular design and integrated components enable customised system planning and fast response to changing conditions. This is made possible by using flexible equipment and machines that can be combined in a modular manner. Using dynamic drive systems and smart control systems, freight can be transported quickly and safely within the entire storage facility. Fully automated vehicles in rack storage systems ensure quick and safe storage and retrieval. The drive technology must be able to manage the weights to be transported and provide the necessary dynamics and precision for the required bearing plays and position accuracies.

Factoring drive technology

The process-optimised open and closed loop control of the storage and retrieval vehicle drive technology is one of the major challenges for mechanical and electrical integration. Drive technology is of critical importance within the overall system - various inherently highly complex issues have to be processed and addressed simultaneously. The several-tonne load to be transported has to be conveyed to the right location at the highest possible speed, along the shortest route, in a three-dimensional coordinate system and without sustaining any damage.

Issues such as availability, performance, energy efficiency, operating costs, spares inventory and maintenance also have to be considered during the design and implementation phases. The building infrastructure must be factored in early enough to coordinate it with the design and the requirements of the drive technology for storage and retrieval vehicles. In addition, provisions have to be made for the comprehensive electrical, mechanical and organisational standards relating to safety and occupational health and safety. During the early planning and the detailed engineering phases, importance is also attributed to electrical design and software integration.

Software and networking

A sophisticated software system monitors, controls and regulates the entire system. Frank Hoffmann, head of Controls/Electrical Engineering says: "The whole control and storage management software is created by the software company of Ldige Industries Group, and is customised." The head of the division has a team of IT and PLC specialists at his side who can draw on longstanding experience, standards and the development of many other projects. This is based on a highly interconnected system comprising a wide range of network devices, such as IT, controls, displays, cameras and weighing scales. The storage and retrieval vehicles together with their drive technology are part of the wired or wireless network.

Efficiency thanks to smart drive systems

The core of the system is the storage and transport system for air freight containers and pallets. On the move there are several elevating transfer vehicles (ETV) with carrying capacities up to about 7 tonnes and storage and retrieval units (RBG) with carrying capacities up to 1.5 tonnes. Whereas Lenze's geared motors are mainly used in conjunction with the Servo Drives 9400 for hoist and travelling drives, Ldige Systems turns to the Lenze Smart Motor and the decentralised 8400 motec frequency inverter for upstream materials handling technology. Frank Hoffmann says: "ETV and RBG are a particular field of drive technology. In Lenze we have found a partner who not only provides technology, but also provides us with drive expertise."

For horizontal materials handling technology, Ldige Systems mainly opts for the Lenze Smart Motor - the combination of an intelligent variable-speed motor with high-efficiency gears. Using this drive approach capitalises on the benefits of being able to quickly commission an AC motor and still be able to work with variable fixed speeds. Owing to this flexibility, the speed of the Lenze Smart Motor - as a drive for roller conveyors - can be easily configured during commissioning and adjusted when connected. Hoffmann explains: "It is always necessary to make adjustments to speeds where there are interlinking conveyor lines." By using the Smart Motor, an extra frequency inverter is not required and the desired speed can be quickly and easily transmitted to the Smart Motor via NFC. For functional and high-performance drive tasks in horizontal material flows, Ldige Systems draws on the Lenze portfolio - opting for geared motors, which are combined directly with the decentralised 8400 motec frequency inverter.

Cooperative engineering

To ensure smooth completion of the tight project in Finland, the Lenze engineering division was involved from the outset. Hoffmann stresses: "It is hugely important to have a partner in the field of drive technology that can cover all interfaces and the whole value-added chain from concept, de-sign, detailed planning, delivery, pre-commissioning and on-site implementation to service and repair and implements this conceptual model in practice." This close collaboration, in his experience, uses cross-checking to enable design errors to be identified early on and avoided. During system commissioning further down the line, "an employee wants to commission his system efficiently without losing time to troubleshooting". In light of ever tighter project deadlines, Ldige Systems chose not to buy any individual motors or frequency inverters, but only ready-to-connect drive solutions. Lenze and Ldige Systems coordinated these beforehand in detail - right down to the software interfaces. As well as contact with the head office in Germany, there is now additional cooperation with the service team from the Lenze office in Espoo, Finland. Involving the Lenze regional office considerably reduces response times due to its geographical proximity.

Tight project deadlines require flexible partners

Speed is so crucial because projects are genuinely pressed by narrow time windows between the completion of structural work and the commissioning of systems. It is thus vital for Ldige Systems to have partners that are results-focused. Trust is reckoned among the key selling points in project implementation. Hoffmann says: "We're required to be able to pull out of the hat fully engineered machines. Therefore, we need suppliers that are flexible and can respond immediately when we need engineering support at short notice during the commissioning phase. I can't afford to have a machine standing for two weeks just because my people can't get a frequency inverter running. Engineering support separates the wheat from the chaff."

With clearly defined interfaces between the mechanics, the electronics and the software, Ldige Systems uses customised drive systems for material flow in logistics centres, including those from Lenze. The collaboration also includes a clearly defined commissioning support package. Only in this way is it possible to pull off complex projects like a cargo terminal within a construction period of less than a year.

Learn more at www.lenze.com.