Posted to News on 13th Jun 2022, 12:26

Future-ready production through robotics and automation

How can global supply chains be made less vulnerable? How can we make production more sustainable and conserve resources? And how to implement a quick transition towards digital production so that the European economy will be powerful and fit for the future?

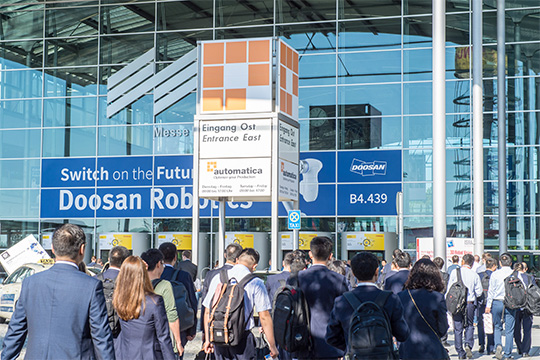

Around 600 exhibitors from all over the world will provide answers to these questions and present solutions for the entire range of automation topics at Automatica, which will be held in Munich from June 21 to 24.

The coronavirus pandemic has shown that the vulnerability of global logistics networks can bring industrial production to a standstill. For this reason, efforts to establish reliable supply chains across Europe are in full swing. And the exhibitors at Automatica will show that intelligently automated production interlinked by digital networks enables economical local production in Europe without risky dependencies.

Eliminating the need to transport components halfway around the globe is directly linked to another hot topic at Automatica: sustainability. All top companies are currently working to become CO2-neutral in the next few years. This can only be achieved through smart production lines based on artificial intelligence, which enable an unprecedented degree of flexibility. Robots, cobots, mobile robotic systems and AGVs as part of a digital network will thus replace inflexible conveyor technology. This enables the conversion of production facilities from one product to another almost at the push of a button without the need to replace costly equipment – all thanks to the smart factory.

The Automatica Trend Index 2022, commissioned by Automatica, proves that manufacturing companies have long recognised the importance of robotics and automation for industrial transformation. It delivers a number of interesting insights, with two key results being particularly noteworthy: 82 percent of respondents believe that the use of robots in domestic production could compensate for supply bottlenecks; and just one percent fewer, 81 percent, believe that robots have the potential to mitigate labour shortages through increased automation, while preventing jobs from being outsourced abroad.

Further analysis shows that these results are a plea for domestic production sites as well as for the relocation of production facilities back to Europe to achieve the overarching goal of making supply chains more resilient.

In addition, 85 percent of specialists and executives consider industrial robotics an opportunity for new business: it enables competitive production of green tech products such as solar panels, batteries for e-mobility, or CO2-neutral heating systems.

The need for automation makes the 2022 exhibition the most important Automatica ever. After the 2020 exhibition had to be cancelled due to the pandemic, and after four intense years of development, an unprecedented firework of technology is to be expected – including AI components, easy-to-use cobots, self-learning robots and pioneering programming tools.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>