Posted to News on 23rd Mar 2021, 09:05

Greater safety in harsh environments

Leuze 3D safety system closely monitors danger zones of machinery and systems

Safety has top priority in industrial environments – and Leuze has a new solution for use in this area: the LBK safety radar system, for use in environments with dirt, welding sparks, sawdust, smoke or humidity.

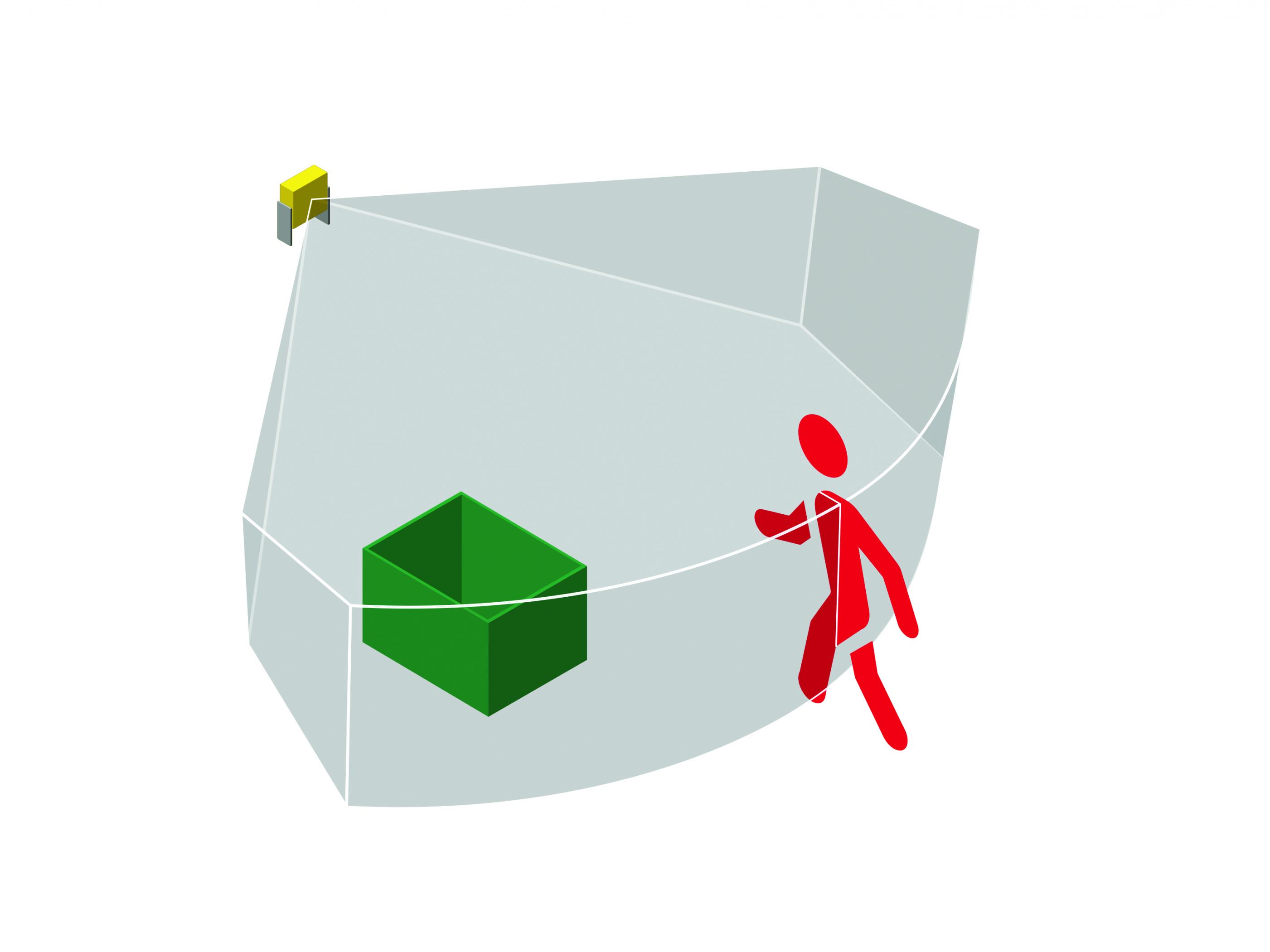

The system safeguards danger zones of machinery and systems – even in harsh environments. "The big advantage of the LBK safety radar system is that it is resistant to environmental influences, and is yet very sensitive and reliably detects movements," says Jörg Packeiser, marketing manager - Safety at Leuze. "In addition, the LBK radar technology monitors a three-dimensional space and not just a two-dimensional surface."

Sensors register movements

The LBK radar system responds to movements and generates a stop signal as soon as a person enters the monitored area, protecting employees, as well as operating processes. This is because the 3D solution interrupts operating processes only if someone actually remains in the danger zone. The system thereby avoids unnecessary shutdowns and, at the same time, increases the availability of the machine or system.

As soon as all persons have again left the danger zone, the machines can start up again. The radar technology can reliably differentiate between people and static objects, because it detects even stationary persons located in the protected area. Static objects, such as pallets or material containers, can be left in the protected area as they do not create a system interruption.

Restart protection

The LBK safety radar system is used primarily for restart protection and for monitoring hidden areas. Users can adapt it to their individual requirements: with the number and position of the sensors, with the adjustable operating range, as well as with the selectable opening angle.

The system also uses its 3D radar technology to monitor areas on steps or pedestals and areas shaded by non-metallic objects. To safeguard larger areas, up to six radar sensors can be connected together via a controller. In this way, the system offers a maximum monitoring area of 15 x 4 meters.

The individual sensors can be connected to form groups. If necessary, these groups can be switched off, thereby allowing the system to adapt to dynamic processes. Another advantage of the LBK safety radar system pointed out by Leuze is that the “easy-to-operate” configuration software can be adapted to define the system parameters.

1B Fenice Court

Phoenix Park

Eaton Socon

PE19 8EW

UNITED KINGDOM

+44 (0)1480 408500