Posted to News on 20th Apr 2023, 12:07

HepcoMotion’s new configuration tool for multi-axis systems

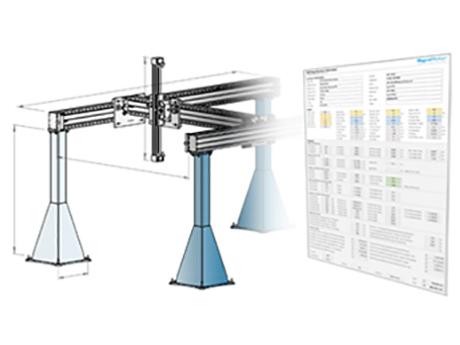

Designed with customers in mind, HepcoMotion is pleased to announce an advanced configuration tool for its HGS gantry systems, which guides customers through all stages of the selection process and enables configuration of multi-axis systems in minutes.

The product configurator quickly calculates bearing, beam and end stop requirements to specify the optimum gantry solution to meet the customers’ needs. With over 50 years of experience, Hepco’s technical department can provide the optimum gantry configuration, saving customers significant design time.

Customers will receive a full technical report including detailed load calculations, assembly, commissioning and maintenance requirements. All required documentation can be provided to demonstrate compliance with essential health and safety requirements and to support CE marking.

Hepco's heavy duty gantry systems (HGS) incorporate the HDS2 heavy duty linear motion elements, which have been used throughout the industry for many years for applications such as palletising, sorting, and pick and place.

In addition to the new specification tool, HGS has several product updates designed to simplify and speed up design time and installation. The introduction of X-Y axes adjustment plates simplifies lifting and handling and reduces assembly time. New X-axis catches mitigate problems caused by abnormal loads, and slide-mounted end stops simplify beam machining. The specification tool will automatically size the gantry mounting legs, which have options for beam adjustment/alignment and foot position adjustment for ease of installation.

The scope of HepcoMotion’s supply has been extended to provide complete stand-alone gantries in most configurations. Motors, controllers, pre-programming and turnkey solutions are all available according to customers’ requirements. The introduction of standard sizes and axes lengths reduces design time and allows quicker turnaround of projects.