Posted to News on 13th Oct 2021, 09:07

High demand for smooth running, precision, durability and cleanliness

NSK develops linear technology components and systems for medical technology applications

Human beings provide the measure: the drives of surgical robots, blood pumps, and MRI and CT equipment (for example) must offer a design that ensures they perform their tasks very precisely and smoothly without emitting any contamination.

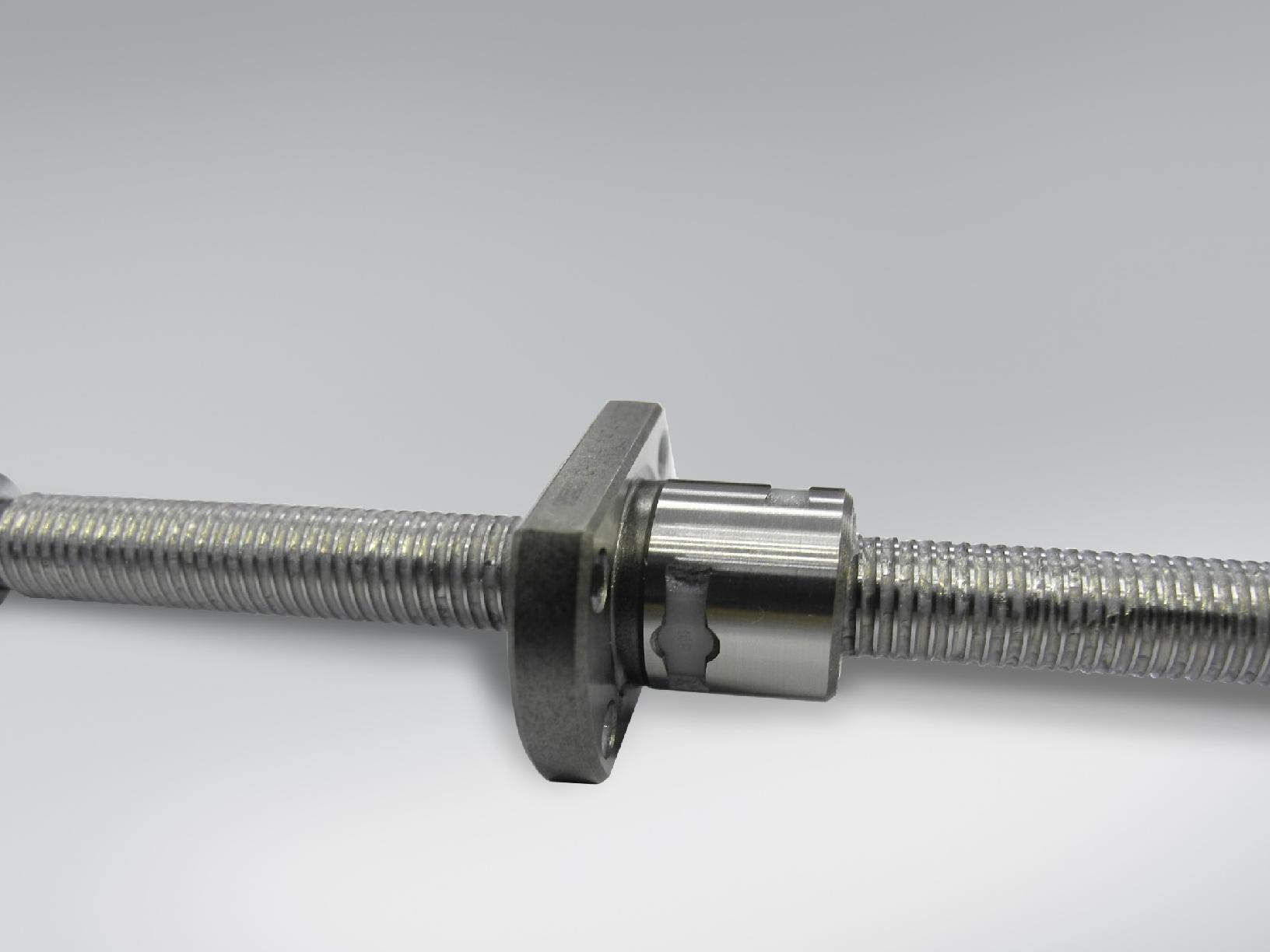

Specifically for facilitating movement in medical technology, NSK provides a continuously expanding range of linear guides and ball screws to suit the smallest installation spaces, it states. Among the many notable features of this product range is a special surface treatment on the raceways of NSK ball screws.

Miniaturisation's critical role

“It is not surprising that miniaturisation plays a central role in this intricate area of application,” says the company. “Surgical robots perform small-scale movements with extremely high positioning accuracy, but low torque in comparison with most industrial applications. Maximum running smoothness is a further prerequisite. Even for blood pumps or cardiac support systems, it is not a question of delivering high performance, but rather a constantly fail-safe operation with excellent running smoothness.”

NSK meets these requirements, it reports, by developing linear technology components and systems with medical technology applications in mind. The company’s offer includes a wide range of miniature ball screws (4-15 mm diameter) and miniature linear guides (size 05-15).

K1 lubrication unit

Many of these components are equipped with the optional K1 lubrication unit, which enables long-term, maintenance-free and thus uninterrupted operation. This minimum-quantity lubrication system also keeps the ball screws and linear guides permanently clean and functional. Specially developed greases are available for short-stroke applications.

NSK’s miniature ball screws also use a special surface treatment on the running surfaces of the ball raceway. A distinctive texture produced by superfinishing creates the conditions for retaining the lubricant within the raceway and for generating only a very low friction torque. “In addition, this effect ensures exceptionally quiet smooth running of the linear components.” To suit certain applications, NSK can also manufacture the components with other types of surface coating.

Ball screw fulfils life-saving task

A ball screw that NSK developed for a manufacturer of mobile cardiac support systems demonstrates the extreme requirements that linear drives need to meet. In such systems, the patient's blood circulation connects via a cannula to a compressed-air diaphragm pump. A miniature ball screw from NSK performs a stroke of up to 55.5 mm, 60 to 130 times per minute. This repeated action forces a defined amount of air against the diaphragm, on the other side of which is the cannula conveying the patient’s circulating blood. Here, the ball screw fulfils a highly sensitive, life-saving task.

When selecting the drive system, the service life of the NSK solution was the decisive criterion. In comparative tests involving various other linear actuators, the NSK product achieved by far the best value, it confirms: around 120 million cycles.

NSK linear actuators in many essential areas

As well as human body applications and surgical robots, NSK linear actuators are also prevalent in laboratory instruments, blood analysis equipment and medical imaging devices, such as microscopes and CT/MRI systems, among others. This applies to individual linear components, as well as complete assemblies (ball screw plus linear guide, for example), and NSK Monocarrier actuator systems with an integrated servo or stepping motor.

Office 4, Arlington Business Park

Gateway 1000

Whittle Way

SG1 2FP

UNITED KINGDOM

0800 634 1909