Posted to News on 18th Jul 2007, 20:54

High-precision coils manufactured for science experiment

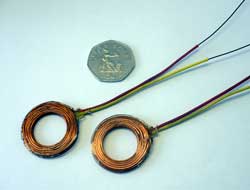

Pre-formed Windings division of Deritend has designed and manufactured high-precision prototype and full-size positioning solenoid coils for the University of Sheffield.

Deritend's Pre-formed Windings division has made a major contribution to the University of Sheffield's participation in the Muon Ionisation Cooling Experiment (MICE), which is designed to understand matter-antimatter symmetry in the universe. Deritend designed and manufactured 30 miniature precision solenoid coils at short notice for the prototype unit, and has since manufactured 90 coils for the full-size version. The coils offer positioning accuracies of approximately 0.0508mm and can operate in high radiation and vacuum environments.

Vernon Fletcher, General Manager of Deritend's Pre-Formed Windings Centre, says: "The University of Sheffield had done a bit of a trawl of coil manufacturers before they found us." The actual coils were manufactured at Deritend's Grimsby Engineering Works, from where Kevin Parrott, General Manager, adds: "The major problem they had was tolerances: these were so exacting that other manufacturers did not want to commit themselves. However, with our track record of manufacturing special coils - up to 12 tonnes in some cases - we saw the project as a challenge, not only because of the tolerances, but also because we had so little time for manufacture. In the end we managed to achieve both objectives, enabling the project to be commenced on time."

The MICE experiment is an important step in accelerating R&D towards the realisation of a neutrino factory, in which an intense neutrino beam is obtained from the decay of muons in a storage ring. Neutrino factories are described as the ultimate tools for precision studies of neutrino oscillations and of leptonic charge-parity (CP) violation, a measurement that might prove decisive in understanding the matter-antimatter asymmetry of the universe.

Linear motion

Sheffield's contribution to the MICE experiment is the design and construction of a target to produce the required muons from the ISIS beam, the world's most powerful source of pulsed neutrons and muons, which is located at the Rutherford Appleton Laboratory in Didcot, near Oxford.

Since the normal uses of the ISIS beam will continue in parallel with the MICE experiment, the target mechanism must cause as little disruption to the ISIS beam as possible: it needs to dip into the beam halo by around 5mm for 2ms (or less) before it is extracted

The target is dipped in and out of the ISIS beam using a linear drive. This consists of a shuttle made of magnetic material, which sits inside the series of coils manufactured by Pre-Formed Windings. When a current is passed through these coils, they induce a force on the shuttle, the direction of which depends on the direction of the current in the wires. In this way it is possible to move the shuttle, and its attached target, backwards and forwards inside the coil assembly, dipping it into and out of the beam.

For more information about MICE see www.cerncourier.com/main/article/45/4/1/1 and www.hep.shef.ac.uk/research/mice/

About Deritend's Pre-Formed Windings Division

Pre-formed Windings, founded in 1968, is part of The Deritend Group Ltd. Based in Sheffield, UK, Pre-formed Windings produces various types of coils for end users, repairers and OEMs around the world. The coils are for AC and DC applications including high-voltage motors and generators, and traction motors.

The division offers extensive capabilities, such as the ability to respond at very short notice, specialised coil designs, 24-hour manufacturing, technical support and experience of export logistics.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Cyprus Street

Off Upper Villiers Street

WV2 4PB

UNITED KINGDOM

+44 (0)1902 392315