Posted to News on 16th Mar 2007, 14:10

How and why to specify cable ducting on machines

Jeremy Procter, Managing Director of Procter Machine Guarding, explains how and why machine designers should specify cable ducting, rather than leaving it to somebody else.

Machine designers often have a mental picture of their machine that extends as far as the control cabinets and the gland plates; cable ducting is viewed as 'somebody else's problem'. But this attitude can lead to a more expensive installation because the ducting has not been properly designed to provide the vital link from the machine to the outside world. Anything that is 'designed on the fly' is likely to take longer to install, will not be as neat, and will cause further problems during subsequent maintenance and modifications.

For machine designers who are unfamiliar with specifying and designing cable ducting networks, there are several points to watch out for. With the vast majority of machine builders now using CAD packages of one sort or another, a great deal of time can be saved if the ducting supplier can provide CAD files of the various components - or, better still, if the supplier is prepared to produce a CAD design of the duct network having been given the machine layouts.

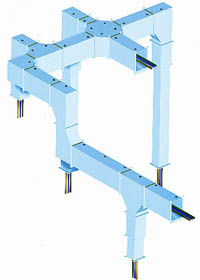

Seldom will a duct network be a straight line between two points, so the duct range needs to include straights, elbows, 'T's and crosses. Going a step further, some suppliers will also be willing to design custom elements to suit the peculiarities of the machine and factory in which it is to be located. Other extras that can make the difference between a professional-looking installation and a 'dog's dinner' include support posts and adjustable ducting connectors.

Aesthetics count

Machine designers are, understandably, proud of their work, so it is only right that the associated ducting network should also look good. Procter Machinery Guarding, which manufactures the Pro-Duct modular cable ducting system, appreciates this fact and even goes so far as to offer customers a choice of colours for the polyester powder coating that is used to finish the components. The ducting can therefore blend in with the machine and surroundings or, alternatively, a striking effect can be achieved if a contrasting colour is specified.

Despite all of these factors, it has to be remembered that the primary purpose of cable ducting is to protect the cables. In most cases it will be adequate to specify ducting that provides protection to the IP54 level described in BS EN 60529:1992 (Specification for degrees of protection provided by enclosures). A further benefit of modular ducting systems is that the installer can be confident that the ready-made components will fit together first time 'out of the box'.

Coping with abuse

Something else that has to be considered for ducting in a factory environment is that it must be able to survive the unexpected. For example, it must be robust enough to cope with the occasional dropped hammer or misplaced foot, which implies that steel is the material of first choice.

Specifiers must also consider not just the purchase price of individual components, but also the cost of installation - labour rates can easily outweigh component costs. In addition, end users will be concerned with the cost of subsequent maintenance and the almost inevitable modifications that tend to be required at some point in the future. As the Pro-Duct system components all use hinged lids rather than the more conventional removable type; cable runs can easily be reconfigured without the need to feed new wires though the network.

Hinged lids, held closed with captive fasteners, provide quick, clear access so that cables may be easily laid directly into an open trough. Moreover, because no parts are actually removed, there is nothing to be dropped or lost, which makes life much simpler and quicker during installation and maintenance.

Versatility

No two machine building projects are ever identical, yet the ducting must always be able to match the requirements. Pro-Duct, for instance, is available in a range of section sizes and, of course, connectors can be supplied to join ducts of different sizes.

Cable ducting is an aspect of machine design that is often neglected, but a far more satisfactory end result will always be obtained by using a professionally designed ducting network rather than relying on a contractor who may end up installing a rough-and-ready lash-up that is clearly the result of a lost race against the clock.

Follow the link to find out more about Pro-Duct cable ducting from Procter Machine Guarding or email [email protected] or telephone +44 (0)2920 882222.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>