Posted to News on 1st Aug 2019, 16:01

How machine builders can address the issue of single-use plastic

Plastic waste deserves no place on our planet. This is the strong and clear message coming from the public and rightly so, but what does it mean for designing and building packaging solutions in the future? Neil Beaumont of Lenze discusses the challenges and solutions available.

Recently, thanks in the main to the Blue Planet series, the UK is waking up to the devastation that plastic wreaks on our planet. This in turn is creating a demand on the manufacturers and supermarkets to address the very serious environmental issue of plastic. There is clearly a need for new packaging technologies: ones that minimise waste and can work with sustainable materials.

For decades though, plastic has been the material of choice for many designers, packaging companies and OEMs. It's light, easily shaped, strong and inexpensive. It guards against contamination, varies in colour, touch and, above all else, lasts forever; it's this last point that negates the materials "hero' status.

The movement to reduce our reliance on the most durable of all materials is undeniable. And it's being driven by the public, businesses, manufacturers and retailers, as well as plastic reprocessor and packaging suppliers. In fact, The UK Plastics Pact brings together 42 businesses from across the entire plastics value chain to tackle plastic waste. These members are responsible for over 80 per cent of the plastic packaging on products sold through UK supermarkets (based on WRAP estimates by weights and market share, using Valpak data). With these companies all willing to make dramatic moves to reduce the use of plastic, designers, engineers and packaging machine builders all need to follow suit, or lead the way.

What does the future look like for the packaging production line? In short, packaging on the whole will be reduced in volume, be reusable or recyclable and/or degradable. This means packaging redesigns and of course, a change in material. The materials are becoming more and more accessible. Product designers have many options open to them such as metal, wood or glass, to name a few. Glass, along with metals like aluminium and steel, can be recycled indefinitely, meaning they don't have to end up in landfills, and wood is also easier to reuse and dispose of. These products are usually more expensive, but their durability makes some believe they're worth the price.

New biodegradable plastics

There are also new forms of biodegradable plastic that are made from renewable sources such as corn, milk protein or keratin from waste chicken feathers, all of which decompose at the end of their useful life or can be recycled. Alternatively, there are companies out there researching the addition of additives that make non-biodegradable plastics, biodegrade.

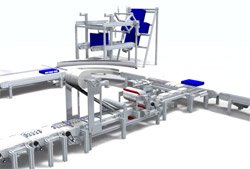

But it doesn't end there! The actual packaging machinery must be able to cope with this shift and be flexible enough to work with a variety of materials. It's a very interesting time and here at Lenze, we're aiming to future-proof the packaging production line. Planning for the inevitable transfer towards sustainable resources is a reality that manufacturers need to address and by building bespoke machines and technology and fully immersing ourselves into our client's needs, means we're already there. We offer highly adaptable systems that can handle all packaging solutions.

In a world where demand for change is obvious, the Lenze automation platform can easily deal with complex machine designs that ultimately improve packaging machine performance and reliability. Our technologies are modular, integrated and flexible which allow machine builders to manipulate the systems to adapt to change in materials. Another ecological benefit is its energy efficiency and the provision of an energy usage monitor that allows operators to make informed operational decisions.

Finding an automation supplier that provides fast, agile and flexible technology is at the top of many company's priorities. And Lenze's experts are well versed with optimising existing equipment or developing new machine systems for a packaging plant. With advancing technologies, coupled with the growth and development of sustainable materials, there really is no reason why packaging production lines can't play their part in helping our planet become "Plastic Waste' Free.

Learn more about Lenze's automation offering at www.lenze.com.