Posted to News on 6th Mar 2017, 10:14

How to leverage e-learning in the manufacturing industry

Niklas Brundin, Wolf-Dieter Hoppe, Johan Treutiger, Carl Reiman and Caroline Dedering, all from Arthur D. Little, discusses how to leverage e-learning for knowledge sharing in the manufacturing industry.

In order for manufacturing companies to respond to today's high speed of change and experience knowledge gap, continuous lifelong learning will be crucial. E-learning will play a key role as it creates effective and efficient opportunities for organisations to improve learning, and to drive change and build relations both within and outside the organisation. To secure sustainable results, organisations have to understand the situations in which e-learning should be used and how to combine it with physical training.

E-learning enables effective learning

E-learning leverages slide shows, videos, gamification and simulation to create interactive discussions and knowledge sharing in digital format. It is a quick and flexible way to train a large number of employees, independent of physical location and time, and creates attractive opportunities to effectively drive changes within an organisation. By using interactive quizzes and tracking methods, e-learning has been shown to increase motivation and learning engagement while making it possible to follow up employees' results, ensuring everyone completes their training modules and gains the essential knowledge. Additionally, with digital material it is easier to maintain, and make central changes to, the learning material compared to traditional non-digital formats - keeping it updated at all times.

One form of e-learning is massive open online courses (MOOCs), which are online courses with unlimited participation and open access via the internet. Participants can be from both inside and outside the organisation. In addition to traditional course material such as filmed lectures, readings and problem sets, many MOOCs provide interactive user forums to support community interactions among students and teachers.

Choose a learning format to suit the information characteristics

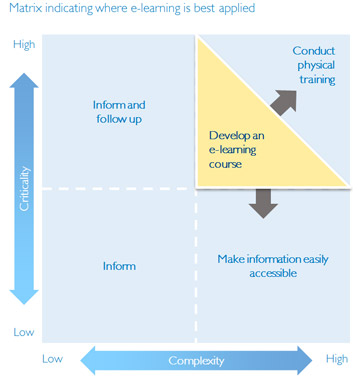

A key question when having information to convey is which method is the most suitable. As different methods each have their own advantages and disadvantages, the most efficient option clearly depends on the situation - and, in particular, the piece of information. Arthur D Little has developed a framework with two key parameters for selecting which method to use for conveying information: criticality, meaning both how important the information is and the number of affected people; and complexity, meaning how complex it is to grasp and understand.

For information with low criticality and low complexity, affected parties can simply be informed (eg by e-mail). If the information has low criticality but high complexity, it is appropriate to make the information easily accessible; for example, by making it available on the company intranet. Information with low complexity and high criticality needs to be actively communicated to the target audience and combined with follow-up activities. Information with both high criticality and high complexity needs to be taught to the target group in order to ensure that it is fully understood and grasped.

E-learning is an excellent substitute for physical training unless the information has both very high criticality and very high complexity. In this situation physical training is unbeatable, as physical presence enables complete customisation, which is required to convey this type of information.

E-learning for different target groups

Within the manufacturing industry there are several beneficial applications for e-learning to train people and drive change. Potential target groups are the internal work force, customers and partners, as described below.

Training of the internal workforce, both blue collar and white collar, is suitable when launching new processes or products. E-learning is also valuable for sharing knowledge within the company.

E-learning is a powerful tool to help customers realise the full potential of the offered products and services throughout the product life cycle. Arthur D Little's experience is that customer satisfaction will increase, and that it strengthens the manufacturer's relationship with its customers. One example of a manufacturing company providing e-learning for its customers is Sandvik Coromant, a global supplier of tools, tooling and know-how to the metalworking industry.

For partners, such as service providers, component suppliers and maintenance companies, e-learning is an efficient option for continuous knowledge transfer. Supporting these actors is a powerful way to improve customer satisfaction and reduce costs throughout the value chain.

Success factors when implementing e-learning

Arthur D Little has identified four key success factors when implementing e-learning:

- Develop a clear strategy covering when and for which types of information e-learning should be used. As part of the strategy development process it is crucial to investigate problems the organisation experiences with current learning practices.

- Ensure user-friendly interfaces in order to simplify usage and continuous updating of the learning material.

- Apply usage incentives and follow-up systems to make sure e-learning is prioritised among the employees. It is powerful to develop courses for specific roles, as well as to implement certifications.

- Align with existing training activities and knowledge management systems. Start with a list of e-learning priority areas focusing on 'must-have' functions rather than 'nice-to-have' ones.

Contact Arthur D Little to find out more about e-learning for manufacturing organisations.