Posted to News on 21st Jul 2015, 09:15

How to select gearboxes for servo motors

This technical article from Techdrives outlines the factors to consider when specifying the optimum gearbox for a servo motor-driven application.

Servo gearboxes differ from standard industrial gearboxes in that they are designed to operate with higher peak input speeds together with a wide operating range. Other factors such as low inertia, backlash and exact numeric ratios can also be important. A common choice for pairing with servo motors is planetary gearboxes that are characterised by compact dimensions and high performance. However, planetary is not the only option and other factors such as the mounting arrangement can lead to alternatives being selected. The key decision factors here are the required torques, gear ratio, level of backlash that is acceptable and the mounting configuration.

Low backlash

Many machine designers look for servo gearboxes with low backlash. Generally the catalogue values for backlash are listed for a torque of 2 per cent of the rated value measured in arcmins at the output shaft. Zero backlash is not a practical option as the lack of clearance leads to elevated running temperatures, but figures as low as 1 arcmin are possible (this is only 1/60th of a degree). More commonly, low-backlash gearboxes are widely available with 3-5 arcmins of backlash.

Of course low backlash comes with a cost. Not only do purchase costs rise, but noise levels can also be higher. Gearboxes will run hotter and the higher temperatures will degrade the lubricant in the long term, resulting in reduced lifetime. Low backlash should therefore be specified where it is needed for reversing drives, where positioning accuracy is needed. Drives that always run in one direction can operate with medium-backlash gearboxes unless external forces can cause movement away from the stopped position.

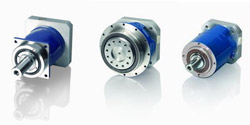

The table below shows four different types of servo gearbox manufactured by Vogel Antriebstechnik, which has specialised in planetary and bevel gears for over 60 years. The optimum choice for many designers will be dictated by the mounting configuration.

Torques and speeds

Servo gearboxes are designed for cyclic duties and the profile of the cycle plus the frequency will influence the selected size of the gearbox. For example, there will be catalogue values for acceleration torque, rated torque and emergency stop torque. The acceleration torque required is simple to calculate and must be below the catalogue limit, if necessary with factors applied for high frequency of operation and high ambient temperature. The rated torque is the limit for the average required torque over a period of time. The emergency stop torque is a limiting value that applies for 1000 stops over the life of the gearbox.

Similarly there will be two catalogue figures for permissible speeds. The maximum input speed is a high value, typically 4000-6000rpm, depending on gearbox size, that must not be exceeded. However, the more important value for selection is the maximum permissible average speed, which will be substantially lower and depends on the load profile. Some suppliers such as Vogel have software to analyse the required duty and optimise the selection. They use the Lenze DSD (Drive Solution Designer) software that can simulate motion accurately for single- and multi-axis drives.

Mounting configurations

Different types of servo gearboxes offer a choice of mounting configurations. Where there is a male shaft, this can have a key and keyway but is often supplied without a keyway. Slight backlash is virtually impossible to avoid in keyways, which can lead to fretting wear on highly dynamic drives. Therefore it is often preferable to use a plain shaft with a friction locking bush. Similarly, hollow shafts can be supplied with or without keyways. Where the option without keyway is chosen, the hollow shaft is extended to one side beyond the gearbox casing and a shrink disc type of locking assembly is used for the connection.

Servo gearboxes are not standardised products and there are a number of variants available. For example, in the planetary types Vogel offers a range with higher backlash suiting lower levels of precision but with a substantially lower cost. Servo planetary gearboxes with flanged outputs instead of shafts are available; not only do these give shorter build lengths, but also bigger bearings in the casing increase radial load capacity leading to their frequent use in robots. The Vogel SKPR is a variant where an additional planetary stage is added to their hypoid range, making ratios up to 100 and torques to 1000Nm possible. Servo gearboxes can also be supplied with ATEX certification.

The desire for high performance with compact dimensions is commonplace in industries such as packaging, printing, robotics, machine tools and military vehicles. Different types of servo gearbox, generally with similar performance, enable designers to optimise a drive. In the UK, Vogel servo gearboxes and geared motors are technically supported and sold through Lenze Ltd.

Follow the link for more information about gearboxes for servo motors from Techdrives, a division of Lenze Ltd.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Lenze Selection (a Division of Lenze Ltd)

6 Abbey Court Road

Priory Business Park

MK44 3WH

UNITED KINGDOM

+44 (0)1234 753201