Posted to News on 6th Sep 2016, 16:48

How to select the right shaft coupling for a rotary encoder

This article from Abssac offers some useful tips and advice for selecting the correct type of shaft coupling for rotary encoder applications.

Too many designers spend time and money on high-accuracy position and speed monitoring devices, such as rotary encoders, only to compromise their performance by using an inappropriate shaft coupling. Shaft encoders are accurate instruments, capable of extremely high angular resolution, and are normally supplied as servo- or flange-mounted units, with protruding shafts. Even the smallest amounts of misalignment between driven and driving shafts can produce side and end loads that will, inevitably, reduce the life of the internal bearings and the accuracy of the encoder.

Drives that impose side loads, such as direct gear couplings, should not be used; likewise, manufacturing rotary encoders with larger bearings does not provide a universal solution. The increase in bearing friction also increases torque, inertia and, in certain cases, shaft windup, which can cause serious limitations in applications, especially where the instrument must respond accurately to acceleration, deceleration or rapid bidirectional stops and starts. Neither is it a solution to couple the encoder via a long shaft whose flexibility accommodates alignment errors, since this potentially introduces vibration problems and, again, greatly increases inertia and windup.

Except in specialised cases where the encoder is integrated with other system components, it is necessary to provide a torsionally stiff, flexible interface between the shaft encoder and the input variable. Usually this takes the form of a flexible shaft coupling. Inevitably, the shaft coupling will impose its own limitations on the system in the form of side loads, increased torque and introduced errors. There are about 35 different flexible coupling designs but, in Abssac's 30+ years of experience, very few are suitable for use with rotary encoders.

A rough rule of thumb can be applied when choosing the correct type of flexible shaft coupling for use with rotary encoders. The following types of coupling should be avoided:

- Couplings that do not provide unconditional constant velocity

- Designs that are incapable of simultaneously accommodating all combinations of angular and lateral shaft misalignment

- Coupling designs with insufficient torsional stiffness

- Designs that transfer excessive side loads on to the encoder bearings

- A mechanical set up that has insufficient axial compliance

- Designs that introduce mechanical backlash into the system

- Shaft couplings that introduce high inertia, friction or vibration

- Designs that are not suitable to the application's environment

Although not one single design of shaft coupling is the answer to all rotary encoder connection problems, the mechanical designer's choice should be based on the particular requirements of the system.

Five candidate couplings

Here we look at five coupling types and consider their suitability. We start with the standard universal joint design and, although this design of shaft coupling is not ideal for encoder use, it illustrates the basic principles of rotary connection.

Hooke's joint

Cardon coupling

Double-diaphragm disc coupling

Bellows coupling

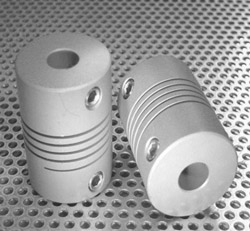

Helical beam coupling

Conclusion

There are some practical considerations for selecting a coupling for positional encoder applications. Always design for the minimum possible misalignment between the driving and driven shafts; the less compensation the coupling has to provide, the better the job it will do and the loads on the encoder's bearings will also be reduced. Both shafts should be close fits in the couplings because loose fits promote imbalance and degrade performance. Remember that at some time the coupling or encoder will have to be removed for maintenance purposes, so that methods of attachment that are too permanent should be avoided. These include the use of anaerobic jointing compounds, grub screws that deform the surface of the shafts they secure to, and force-fits. The use of excessive force when dismantling can damage the shafts and bearings of associated components, not least in the encoders.

Follow the link for more information about Abssac's shaft couplings for rotary encoders and other applications.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>