Posted to News on 22nd Jul 2011, 14:29

HSE reduces machine inspections, so users must do more

Jeremy Procter, the Managing Director of Procter Machine Guarding, explains how the HSE's reduction in proactive inspections requires employers to be more rigorous in assessing their own safety.

In March 2011 the UK Government revealed what further steps it would be taking to reform health and safety system. Following on from this, in May 2011 the HSE (Health and Safety Executive) and the Local Government Group jointly published a statement to help local authority (LA) regulators determine how and when to use proactive interventions (usually taking the form of unannounced inspections). Available to view as a PDF, the document is entitled Joint guidance for reduced proactive inspections (96kB PDF).

On the one hand, businesses may be relieved that they no longer have to be prepared for visits by inspectors, though high-risk premises might still be inspected at any time (see the HSE's publication HSC14, What to expect when a health and safety inspector calls). In fact the aggregate number of inspections is only expected to fall by one-third.

However, the reduction in proactive inspections means that businesses need to be more careful about their health and safety - and not take the view that any shortcomings will be identified for them by an HSE inspector. Moreover, the HSE will be placing a greater emphasis on reactive work, so any complaints, accidents or incidents may be investigated more rigorously.

Employers have an existing duty under the Provision and Use of Work Equipment Regulations 1998 (PUWER 98) to ensure the safety of work equipment. Most companies have now undertaken PUWER inspections, but it should be remembered that PUWER requires equipment to be inspected to ensure that it continues to remain safe to use. Although no inspection period is mandated (it depends on the nature of the risks), annual inspections should be considered as a starting point.

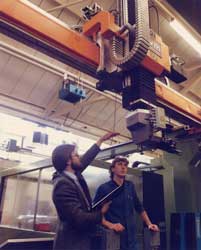

Machinery inspections

In addition to PUWER, employers have obligations under the Health and Safety at Work etc Act. Considering these two pieces of legislation together, and the fact that an HSE inspection is less likely than before, it is essential that employers check their work equipment periodically. While this is relatively straightforward for equipment such as hammers and knives, machinery inspections require a higher level of competence. For example, it is insufficient merely to check that the original safety measures are still in place and operating as required, because the measures on old equipment may no longer be deemed adequate.

To help employers meet their obligations, Procter Machine Guarding offers free Guarding Compliance Surveys, which are suitable for almost all potentially hazardous types of machinery, ranging from standalone machines to complex assemblies. After an initial telephone consultation, safety engineers can make an appointment to visit an organisation's premises and assess the machinery safeguards. At the end of the survey the engineers provide a short written report that identifies any areas of non-compliance and actions that can be taken to reduce risk, improve safety and comply with the Regulations. Importantly, Procter can also carry out any work necessary to bring the machinery up to standard.

In addition, Procter Machine Guarding has published a free Guide to Workshop Safety that will benefit anyone responsible for the safety of machinery and work equipment. Packed with advice, hints and tips, the guide includes sections on the following topics: costs and benefits; regulations and legislation; general requirements for machine guards; specific machine types; other measures relating to machinery safety; standards; official information and guidance; useful resources; and sources of further information.

To obtain a PDF copy of this publication, follow the 'Downloads' link at www.machinesafety.co.uk. Alternatively, follow this link to enquire about free Machine Guarding Compliance Surveys, email Procter Machine Guarding at [email protected] or telephone +44 (0)2920 855758.