Posted to News on 4th Sep 2015, 13:10

igus e-chains help keep frost at bay

The seemingly simple bag of peas can, in addition to being a bag of tasty foodstuff, be used to provide handy relief of pain and inflammation from sports injuries. But have you ever wondered how the food processing industry can freeze peas individually?

The IQF (Individual Quick Freezing) method allows food manufacturers to continuously freeze small-sized individual products, it is more commonly known for freezing fruits and vegetables, but has further developed to cover a much broader range. Using this freezing technology it enables the usually difficult to freeze food types to be carefully handled and effectively processed.

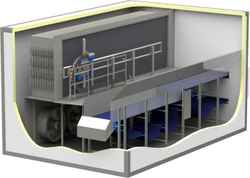

Starfrost, experts in the field of freezing technology, has supplied industrial IQF freezers and chillers to food manufacturers for over three decades. IQF Freezers are designed to first crust freeze the surface of the individual food item before the product is then transferred to the deep freezing stage, often to temperatures down to -32degC. With product capacities ranging from 500 to over 20,000kg/hr, these machines frequently operate over long periods of time - especially during the harvest season, when time is money.

A challenge which is often encountered within the inline freezer industry is the frost which can build up on the fin face of the evaporator; this can reduce the energy efficiency of the equipment, and, at regular intervals, would require a maintenance shutdown to remove the frost build-up, both of which are costly in the food processing industry. One option would be to install complex sequentially defrosting evaporators, which are expensive and difficult to maintain. However, Starfrost designed a new, innovative system featuring the igus cable tracker, to resolve this problem.

Starfrost has developed a Frost Removal System (FRS) that blasts dry, compressed air in a pulsed motion across the fin face of the evaporator to eliminate the frost build up. In the original prototype of the FRS design, the cables and air hose supplying the carriage, which moves up and down to remove frost build-up, were prone to snagging during operation. In addition, the unsupported high-pressure hose impeded the movement of the carriage making it difficult to position the air nozzles accurately.

Robert Long, Sales Director at Starfrost comments: "These initial teething difficulties were creating more production shutdown problems than the FRS was designed to solve. We needed a solution that would be operational at these sub-zero temperatures, while supporting and guiding the cables and hose. In addition, the unpredictable movements of the high-pressure hose meant it had to be restrained and controlled more rigorously."

Support system

As a renowned cable tracking expert within the industry, Starfrost approached igus for a support system for the cables and hose. Working together engineers at Starfrost and igus developed an approach that allowed the FRS to run smoothly and efficiently, without the cables and hose snagging or moving out of position.

In the final design, the FRS cables and hose were housed in the frost-resistant e-chain - the robust and reliable energy chain supported and constrained the cables and hose inside, which protected them from getting caught up on the machinery. Resistant to extreme temperatures and easy to clean, while being self-lubricating and requiring no maintenance, the igus e-chain proved a reliable option for Starfrost's FRS design.

Justin Leonard, director at igus comments: "Starfrost and igus worked together in the design process in order to ensure a problem-free installation and functioning. In total, the igus e-chain has been used in three machine installs, two of which are overseas. We are delighted to have worked with Starfrost on this application and achieve such positive results".

Robert Long concludes: "Throughout the development process, igus were co-operative, flexible and responsive to our needs. The final FRS design has proved beneficial to our equipment's performance, keeping frost at bay, extending running times and maintaining evaporator efficiency - without the need to install complex sequentially defrosting evaporators."

To learn more about frost-resistant e-chain and other products from igus please visit the website at www.igus.co.uk.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>