Posted to News on 2nd Mar 2022, 08:54

Inductive heat for precise and sustainable assembly

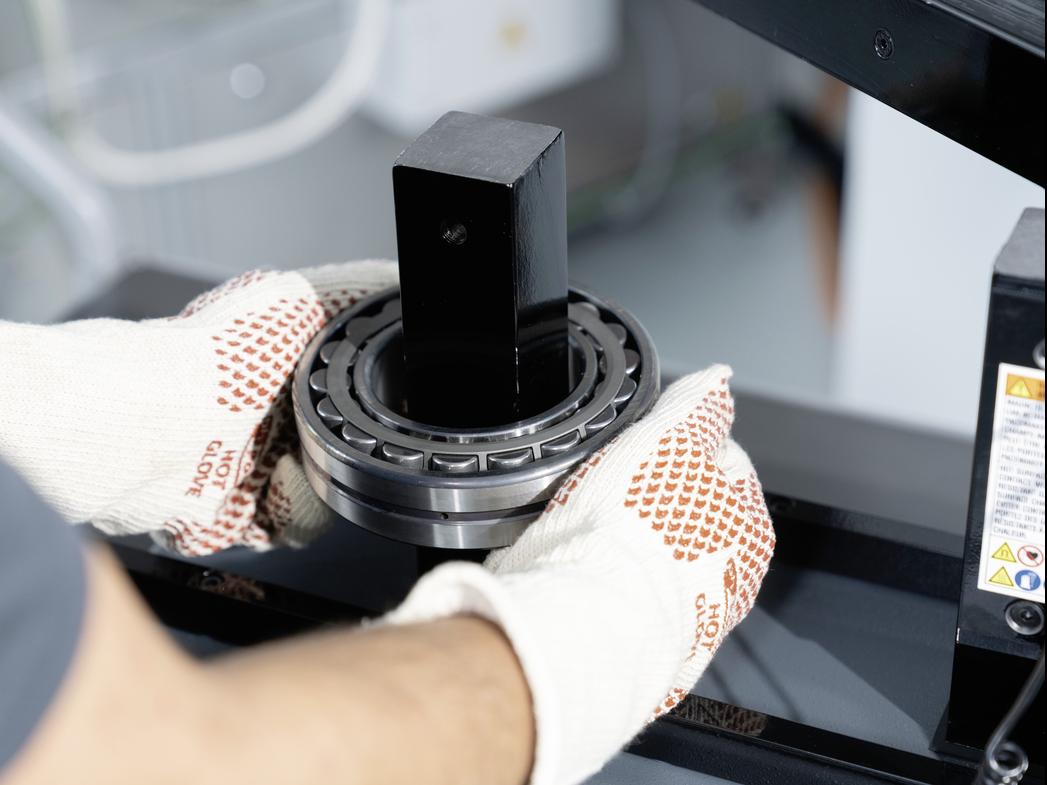

Schaefflers new range of induction heating devices focus precisely on needs of fitters

Precision, energy efficiency, safety and time saving: These benefits give induction heating an advantage over methods such as special ovens, oil baths or gas burners, says Schaeffler.

The company has now launched HEATER-BASIC and HEATER-SMART, a wide range of induction heating devices that focus precisely on the respective application needs of the fitters. The HEATER range is the first launch of an induction heating product from Schaeffler since the acquisition of special tool manufacturer BEGA International as a wholly owned Schaeffler subsidiary in July 2021.

Wide range of applications

The two product series HEATER-BASIC and HEATER-SMART provide fitters from various industries with a wide range of applications, depending on their needs and requirements. “The uniform, controlled and thus careful heating of the work components supports a consistently high assembly quality,” adds Schaeffler. “Damage during assembly is prevented and, at the same time, the bearing lubrication is maintained, which significantly increases the service life of the work components. The energy-efficient heating technology reduces operating costs and working times and does not produce any by-products such as residual oil requiring disposal and unused waste heat.”

Selecting the right device

The HEATER-BASIC and HEATER-SMART series have been launched as table-top and floor-standing devices, and can be used to heat work components weighing between 20 kilograms and 1,600 kilograms. The respective model designation provides direct information about the work component capacity and, as such, helps fitters to select the right device. “The heating process is controlled via a particularly robust membrane keypad, which also enables convenient operation during direct work use. Especially important with large devices: these models are mobile and equipped with an ergonomic swivel arm, which makes handling much easier for the fitter.”

Delta-T control

The SMART models have a delta-T control, which allows roller bearings with a low radial clearance in particular to be heated optimally, further comments Schaeffler. “The fitter controls two temperature sensors separately for the inner and outer ring, in order to be able to heat the work component safely and without reduction of quality. The user selects the heating temperature and the maximum temperature difference on the device. This difference is continuously checked during the warm-up phase and the device reduces the power if the difference moves too quickly towards the maximum values.

"In addition, the models of the SMART series are able to precisely document the heating process. This is important wherever maintenance and servicing work needs to be tracked in detail at all times – for example, in particularly safety-related applications.”

Continuous expansion of assembly products

Schaeffler is further expanding its product portfolio of innovative assembly tools with the HEATER series. Following the launch of Laser-EQUILIGN2 for optimum shaft alignment in October 2021, further products from the inductive heating technology range have already been scheduled for 2022.