Posted to News on 20th Oct 2021, 08:57

Integrating electric motors into smart factory systems

Analytics-driven predictive maintenance promises machine builders competitive edge

The use of analytics-driven predictive maintenance is on the up, with 80% of manufacturers having some sort of predictive maintenance programme in place and half of those using analytics to drive decision-making.1

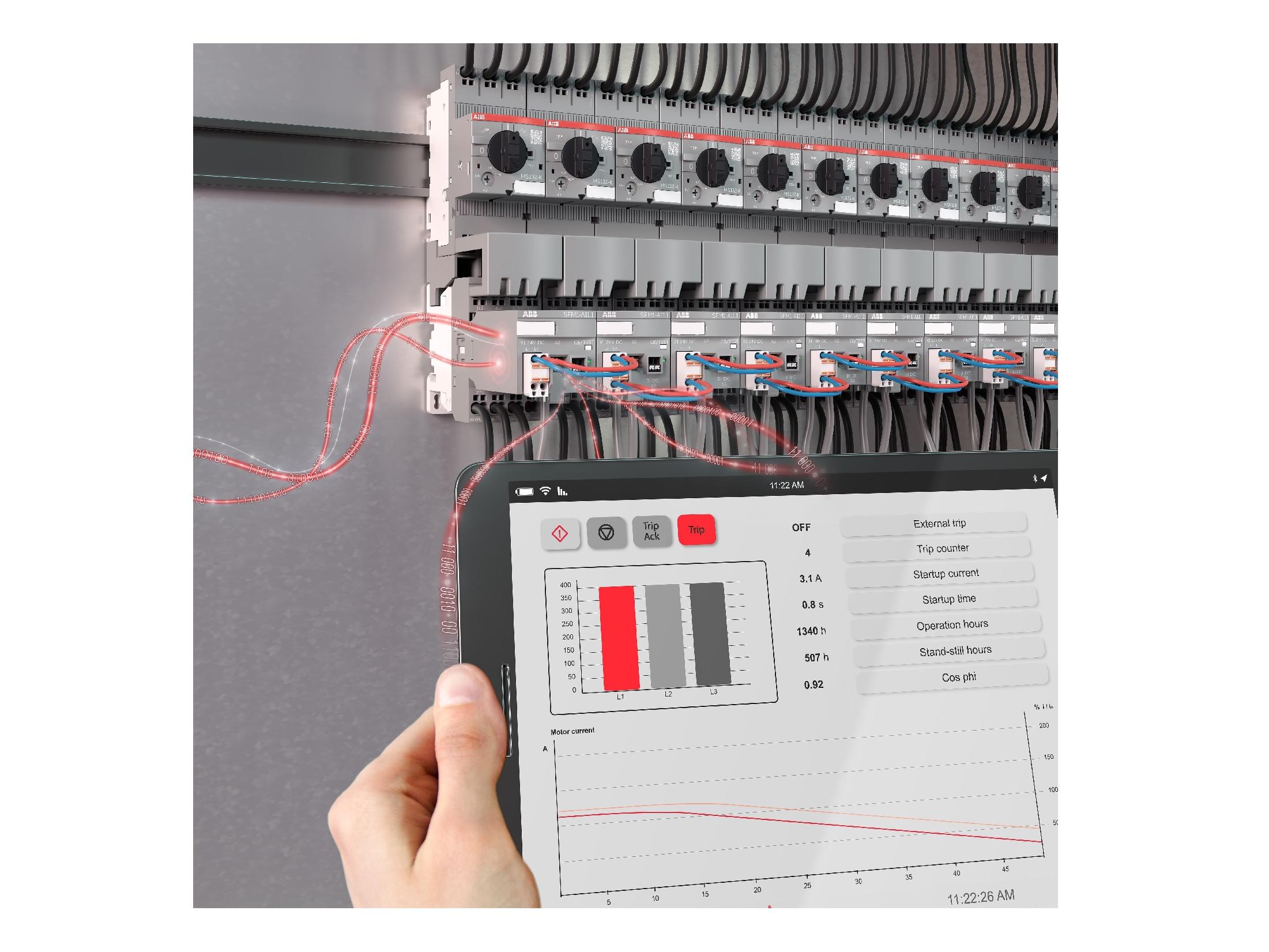

When it comes to energy hungry sub-systems, such as electric motors, predictive maintenance can optimise performance and improve uptime. If contactors, managing motors and other equipment are digitally connected to cloud-based monitoring and analytical systems, facility owners on the road to smart factory status can use real-time data to improve the accuracy of their predictive maintenance programmes.

In this article, Hussain Ahmed, global digital product manager (Motor Starting & Safety) for ABB Electrification’s Smart Power business, explores how digitally connected motors can allow end users to harness the benefits of predictive maintenance to maximise the efficiency of their motor systems. He also explains “how easily contactors can be connected to B&R Programmable Logic Controllers (PLCs)”, allowing machine builders to better serve smart factories and autonomous environments.

When it comes to motors, energy-efficiency strategies are often focused on the motor management system, rather than the motor itself. While this is a logical strategy, it is important not to overlook the significance of a well-maintained motor on overall motor management system efficiency – it is, after all, the central energy source of the machine.

To maintain a motor to the highest standards and reap the benefits of a motor management system, predictive maintenance processes are a proven strategy, and favoured by factories on their digitalisation journey. Digital solutions like ABB Ability Energy and Asset Manager allow manufacturers to use cloud-based analytics to monitor multiple assets and sub-systems from a single interface and make informed decisions, based on data insights into the status and condition of their assets.

Machine builders who take these aspects into consideration when installing connected motor management systems during the build phase will be best placed to serve the growing smart factory market.

Benefits of predictive maintenance

Statistically speaking, running a piece of equipment to the point of failure is estimated to cost up to 10 times as much as a regular maintenance programme and, according to the US Department of Energy, predictive maintenance saves up to 40% over reactive maintenance procedures.2

There is no surprise then that the overall use of predictive maintenance is on the rise, fuelled not only by the cost and time benefits it brings, but by the global shift towards connectivity and the Industrial Internet of Things (IIoT). This has been further compounded by the COVID-19 pandemic, which has restricted travel and site access, making the need for predictive and remote maintenance ever more pressing.

Importance of predictive maintenance for motor systems

In some countries, motor systems account for around 70% of manufacturing electricity consumption, which translates to approximately 30% of the world’s entire electricity usage.1

Ensuring that motors are well maintained on a predictive, and not a reactive, basis can optimise their performance and the output of the wider system.

Research proves that only around 10% (and maybe even less) of industrial equipment can physically ‘wear out’, which means over 90% of mechanical failures are avoidable. This goes for motors, too, which is why predictive maintenance of this critical sub-system, using solutions like ABB Ability Energy and Asset Manager, should be high on the agenda for advanced machine builders and their customers.

Data-driven predictive maintenance for contactors

As factories move in favour of IIoT (Industrial Internet of Things) and connected manufacturing becomes commonplace, maintenance engineers are harnessing the power of real-time data to digitally predict when maintenance is required. This allows downtime to be scheduled for when production demand is off-peak and spare parts are already onsite.

By continuously monitoring and reporting system variables, such as connected loads, electrical measurements and significant maintenance aspects, solutions such as the ABB Novolink allow maintenance engineers to increase efficient motor operation and reduce costs of running by maintaining the motor in its optimal working condition.

Life source of the system

Most importantly, because the motor is the life source of the system, predictive maintenance allows asset owners to predict potential issues with the motor and wider connected equipment, enabling them to plan demand and customer expectation around any unavoidable downtime.

Connecting contactors using Novolink is easier than some machine builders may think, with quick and easy digitalisation solutions already available on the market.

ABB Novolink offers the highest levels of out-of-the-box digitalisation, connecting directly to AF contactors with no specialist cabling. The device simply snaps on to any AF contactor from AF09 to AF96 with a 24 V DC coil, using an advanced electronically-controlled magnet system that covers the complete power range.

Predictive maintenance for motor management systems, using systems like the ABB Novolink, identifies issues early on, keeping maintenance well ahead of any problems, so that they can be resolved far quicker and have significantly less impact on factory output.

Benefits of connectivity for machine builders

To remain competitive, advanced machine builders must meet the growing demands of the smart factory revolution. The global smart factory market was valued at USD 252.29 billion in 2019 and is expected to reach USD 422.88 billion by 2025.³

The smart factory represents a leap forward from more traditional automation to a fully connected and flexible system, capable of using a constant stream of data from connected operations and production systems to learn and adapt to new demands.

A true smart factory can integrate data from around the facility to drive manufacturing, maintenance and inventory tracking. Designing machines that can accommodate this level of connected performance is essential to service this growing segment of the global manufacturing market.

Simple, cost-effective connectivity solutions like the ABB Novolink for contactors are an effective addition to the digital compatibility portfolio of an overall system and give machine builders a competitive edge in a noisy marketplace. More importantly, they can be implemented in a step-by-step approach, where the business benefits mean that the connected assets will soon pay for themselves.

1 Maintenance Statistics: Predictive & Preventive, Labor & Costs (onupkeep.com)

2 Infographic: The Profile of Energy Use in Industrial Motor Systems — Global Efficiency Intelligence

3 Smart Factory Market | Growth, Trends, Forecasts (2020 - 2025) (mordorintelligence.com)

ABB Automation Technologies (Drives and Motors)

3100 Daresbury Park

Daresbury

WA4 4BY

UNITED KINGDOM

44 1925 741 111