Posted to News on 23rd Oct 2020, 08:58

Kinoulton company conveys COVID-combating masks

Here's a great example of the germ of an idea resulting in the combating of COVID

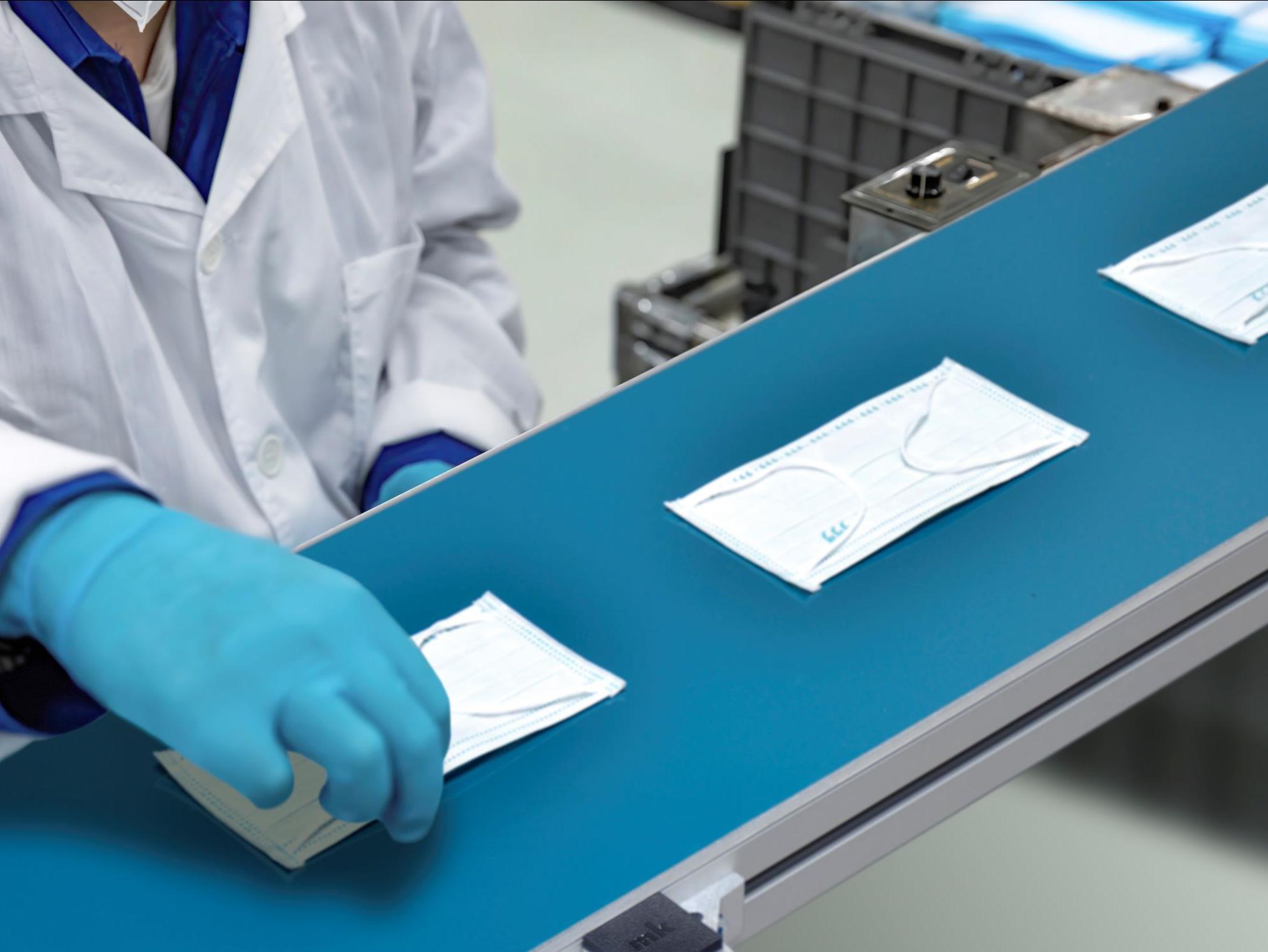

Kinoulton-based mk was recently asked to deliver a large number of conveyors to a long standing customer in an extremely short time frame, as part of the ongoing battle against the spread of COVID. The equipment was urgently needed for a plant producing up to 100 PPE masks/minute using a fully automated process. Given the countrywide supply chain pressures as part of the COVID response, the customer was keen to lay hands on the new conveyors and have them operational in double-quick time. They are being used to move the masks between separate parts of the production line (folding, bonding and supplying nose clips) and then onward for disinfection, all over a 3-shift system.

Working alongside the customers’ design team, mk staff configured a conveyor consisting of as many standard components as possible, but which still satisfied the necessary cleanliness requirements for the application. An mk GUF-P 2000 conveyor was chosen for the job and mk delivered 40 of them in just a few weeks, and at competitive cost thanks to the high level of standardisation and the use of stocked parts. An FDA-approved belt was used in order to keep the masks free of contamination, and mk specified low-maintenance, indirect drives with timing belts for the conveyor to ensure that the three-shift operation runs reliably and without interruption.

Unit 11-12 Wolds Farm Business Park

Kinoulton Lane

NG12 3EQ

UNITED KINGDOM

+44 (0)1949 823751