Posted to News on 11th Jul 2011, 23:01

Laser line scanner inspects run-out of complex gears

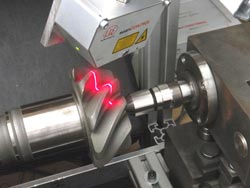

Micro-Epsilon's has supplied a scanCONTROL 2800-25 laser line scanner to EHR for use in an optical measurement system that checks the run-out characteristics of complex gears.

Gear shafts with plug-in teeth, bevel gears, hypoid teeth and other similar axial components can warp during manufacture, requiring inspection of the run-out. In order to adjust the workpiece, the extent of the ovality and the direction of adjustment need to be determined. Engineering company EHR has developed an optical measurement system was developed specifically for this purpose, enabling rapid, extremely precise automated correcting of the workpiece.

The scanCONTROL 2800-25 is aligned with the component in such a way that the laser line is perpendicular to the gear teeth. By rotating the clamped component, the entire tooth area can be scanned to create a 3D point cloud, which is then evaluated according to customer requirements. In order to make a comparison with tactile dislocation, computer-generated digital balls are placed between the flanks of the teeth.

Another benefit of using 'digital dislocation' is that the diameter of the ball can be changed quickly and easily. All ball diameters that should pass between the gear teeth can be selected using simple configuration tools. Due to this increase in the number of evaluation results, measurement accuracy of better than 5um is achieved, which is better than the measurement resolution of the laser scanner.

Sensor and controller

The Micro-Epsilon scanCONTROL 2800-25 comprises a compact sensor and an intelligent controller, which are connected via a cable. The controller outputs both the 2D profile information as well as the analysed data. An integrated FireWire/Ethernet interface enables complete control for multiple scanCONTROL systems via a PC, as well as high data rates.

A profile generated by the scanCONTROL 2800 consists of a maximum of 1024 points and a calibrated measurement value each for X and Z. These points are acquired simultaneously across the entire line and made immediately available to a PC for real-time evaluation of the profile. The sensor provides a profile frequency of 4000Hz and up to 256,000 measuring points per second.

Follow the link for more information about Micro-Epsilon's scanCONTROL 2800-25 laser line scanner. Alternatively, call the sales department on +44 (0)151 355 6070 or email [email protected].

No. 1 Shorelines Building

Shore Road

CH41 1AU

UNITED KINGDOM

+44 (0)151 355 6070