Posted to News on 22nd Feb 2023, 15:39

LG Motion engineers the perfect printing technique

See LG Motion at MachineBuilding.Live, 4 October 2023, on stand 13

LG Motion recently received an enquiry from a student at Southampton University to design a reverse offset printer to complete a PhD developing high-definition printed electronics.

The School of Electronics and Computer Science (ECS) at the University of Southampton was rated 1st in the UK by the Guardian University Guide 2022. LG Motion was approached by Russel Torah, principal research fellow at the university, to discuss a concept designed by one of his students to engineer a motorised reverse offset printer.

Reverse offset printing (ROP) is receiving increasing attention as an emerging technology for printed electronics due to its rapid, environmentfriendly fabrication processes. Working closely with the team at the University of Southampton, the printer was engineered to be as versatile as possible to allow for adjustments to user requirements during the course of the research.

The printer acts similarly to stamping on newspaper printing, creating a negative for sub-micron level printing and will ultimately be capable of achieving much higher resolution compared to standard screen printing for printed electronics applications. A number of different electronic inks, such as conductors, dielectrics and electroluminescent materials as well as multi-layer printed electronic devices are targeted for development with this new printer.

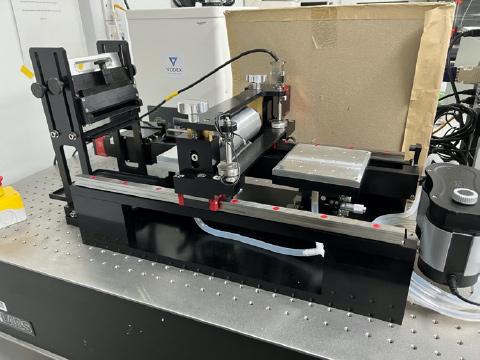

A motorised reverse offset printer was designed with future development in mind, ensuring the unit was rigid and provided flatness of travel in relation to the contact areas, with complete linear bearings to provide stability and straightness of travel and a control system that provided flexibility of operation.

The printer was manufactured from aluminium with a black anodised finish to assist with ease of cleaning down the inks between projects. The linear slide is driven with a ball screw on linear guided rails with the drum rotation on a separate motor, with the ability to vary speeds to achieve synchronisation with the linear slide to aid printing technique development.

The workpiece is mounted on two XYZ micro-positioners that have been integrated into the system, complete with a vacuum plate for securing the workpiece during operation. Upon successful trials the offset printer will be scaled up to a much larger machine.

“This new research tool provided by LG Motion will significantly enhance research capabilities provide considerable versatility for development within the new Centre for Flexible Electronic and E-textiles at the University of Southampton,” said Torah.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 1, Telford Road

Houndsmill Industrial Estate

RG21 6YU

UNITED KINGDOM

01256 365600