Posted to News on 15th Nov 2021, 08:57

Lifts per twirl - converting a rotational input to linear

Leading the way with the power of lead screws

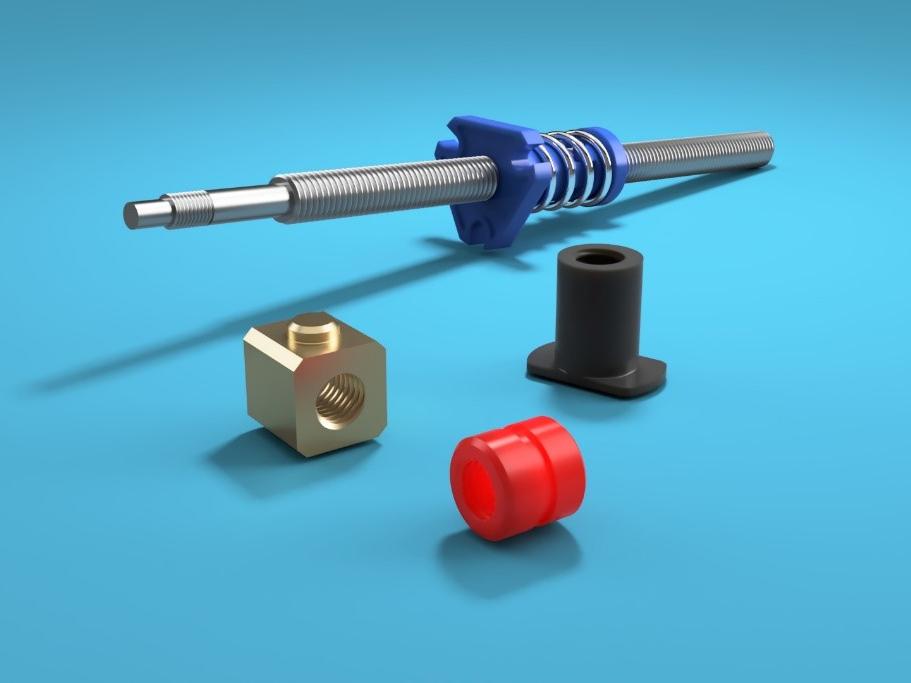

Leadscrews encompass power, miniature and high helix thread forms, all of which are a dependable way of converting a rotational input into a linear output (or vice versa) and can be found in a plethora of applications, as linear, rotary and special power transmission products supplier ABSSAC points out.

The end product is manufactured by grinding, machining or cold rolling methods, resulting in round bar stock being transformed into the threaded bar. There are many thread formats, the most common being acme or trapezoidal, with the linear accuracy of the thread form being indicative to the manufacturing method employed, as well as the unit cost.

Wide range of diameters, wide choice

Leadscrews are available in a wide range of diameters, with an equally large number of leads. (The lead of the screw being the axial advance of a helix during one complete turn – 360° – or, in the case of a lead screw, it is the axial travel for a single revolution. Pitch being defined as the axial distance between adjacent threads on a helix or screw.)

To effectively translate a rotation of the thread form (leadscrew) into a linear movement, each leadscrew needs to be paired with a nut that has the same internal thread as the external thread of the leadscrew. Which combination of nut and leadscrew is chosen directly effects the linear performance and accuracy.

Accuracy and life within budget

In most leadscrew applications, the engineer’s main challenge is to obtain a linear device, with a desired linear accuracy and life, but within budget, with cost normally increasing with greater precision.

- Precision leadscrews and bespoke design nuts are available from 6mm to 20mm in diameter.

- Leads from 1mm to 50mm

- 5micron per 300mm of travel to 200 microns per 300mm of travel

- Imperial-sized leadscrews are also available as standard

- Power screws are available from 8mm to 120mm in diameter, with full design capability of associated nuts

- Leads from 1.5mm to 40mm

- 100 microns per 300mm for steel and 200 microns per 300mm of travel for stainless

- Imperial-sized leadscrews are also available as standard.

Many leadscrew nut designs exist. They can be simple backlash designs through to complex antibacklash, preloaded, multifunctional designs, all of which can be chosen to be specific to the application parameters. “ABSSAC works closely with customers to supply a finished ready to fit product and ensures that the leadscrew and nut fit tolerance is maintained every time,” the company states.

Custom lead screw features supplied in the past have included:

- End Journals to suit bearing mounts

- Threaded Journals

- Flats

- Slots

- Keyways

- Chamfers

- Tapers

- Cross Holes

- End Holes/Gun drilling

- Internal Threads

- Bearing Reliefs

- Snap Ring Grooves

- E Clip Grooves

- Full Radius Ends.

ABSSAC also offers an assembly service

- Multiple Piece Lead Screws – Product designs that comprise several components

- Multiple Component Lead Nuts – Custom drive nut assemblies in plastics or metals

- Cross and End Pins

- Complete sub-assemblies

- Press and Slip Fits

- Hand Fitting and Lapping

- Bearing Installation

- Glue Application

- Thread Locker Application

- Auxiliary Assemblies

- Fastener Installation

- Sealing and Packaging.

The next consideration when choosing a leadscrew is how the leadscrew is physically attached to the system. There are a number of thrust and radial bearing variants to suit all applications. The load, the distance between shaft ends and the required speed are some of the parameters that have an effect on which bearing type is used.

“ABSSAC has a reputable machining capability, enjoyed by numerous customers, that delivers an excellent journal concentricity product, regardless of diameter, that is ready to fit into supplied bearing mounts or application,” it points out.

“The leadscrew and nuts can then be combined with a full range of linear guides and rails that provide load support to the linear mechanism. The guides offer excellent rigidity and parallelism during operation, and can be used in both vertical and horizontal planes.”

The end result is a very reliable and capable linear system, adds ABSSAC, that “is also extremely confident in the reverse engineering of linear product, should original drawings not exist”.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>