Posted to News on 1st Jul 2007, 14:12

Light curtain muting achieved with inductive loops

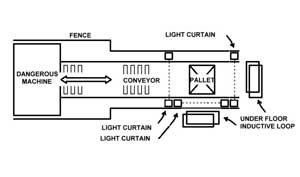

Smartscan is promoting an effective system for the automatic muting of safety light curtains at forklift truck load and unload areas. The safety-related inductive loop control system is typically used on in-feed and out-feed conveyor access points at hazardous machines such as pallet stretch wrappers, pallet shrink wrappers, de-stackers, de-palletisers and robotic handling systems.

The Smartscan inductive loop controller controls the muting function within the light curtain by detecting the metallic mass of the forklift truck passing over the twin inductive loops installed under the floor in front of the zone protected by the light curtain. When a forklift truck is detected, the loops provide dual signals to the controller, which are monitored and processed to provide failsafe muting signals to inhibit the light curtain during periods when the forklift truck is loading or unloading pallets from inside the potentially dangerous area.

One of the many advantages of the inductive loop system is a marked improvement in the ease of use for the forklift operator. The system is fully automatic, providing continuous but safe operation of machinery by removing the need for manual resetting of the system by the forklift truck driver, with the obvious benefit to productivity. Systems are available for single or multiple access points.

Smartscan has been successfully supplying its specialist safety light curtain guarding system to end-of-line packaging machinery applications for over 10 years. The company offers a full installation and maintenance services.

A free booklet explaining packaging machine safety methodology is available from Smartscan on request.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>