Posted to News on 23rd Jan 2009, 10:11

Locking bush is quick to release for machine cleaning

An ETP-Express locking bush from Lenze Ltd has been specified for a food production machine, as the bush is cost-effective to purchase and install, plus it saves time when the machine is disassembled for cleaning.

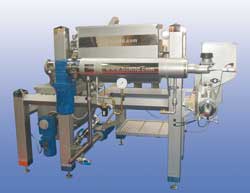

BCH Ltd designed the Micro Extrusion Line as an economical way to handle small production runs of extruded liquorice. Ease of cleaning is an essential requirement and the connection between the drive gearbox and rotary heat exchanger needs to be regularly stripped down. To make this process quick and simple, BCH has selected the cost-effective ETP-Express locking bush from Lenze Ltd.

Raw materials are heated in a scraped surface heat exchanger called a Viscotator, which is effectively a heated tube with an internal shaft and blades. The raw materials are pumped through the tube under pressure and their temperature increases by about 100degC. The Viscotator is driven by a Lenze helical bevel geared motor, which was chosen to cope with the high axial loads from the pumped ingredients. In operation it is necessary to disconnect the Viscotator shaft from the gearbox for cleaning at least every two weeks. Keyway and spline arrangements were rejected, as keyways are liable to wear over time and jam, and splines are expensive to machine and require a non-standard gearbox that incurs extra cost and a longer lead time.

Developing the Micro Extrusion Line for small production runs enabled BCH to rethink its design. Combining the Lenze gearbox with an ETP-Express bush gives technical advantages - being quick to fix and capable of transmitting both torque and axial loads - as well as cost reductions compared to splines. The final advantage for the machine users is the time saved when the machine needs to be cleaned.

Follow the links for more information about ETP Express locking bushes and to view short animations on YouTube.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Lenze Selection (a Division of Lenze Ltd)

6 Abbey Court Road

Priory Business Park

MK44 3WH

UNITED KINGDOM

+44 (0)1234 753201