Posted to News on 9th Mar 2010, 17:40

Locking bush prevents damage in the event of machine jams

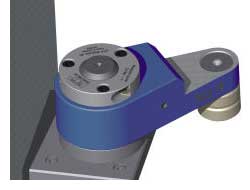

A manufacturer of blow moulding machines is fitting ETP-Express locking bushes to lever arms that open and close the moulds, as they prevent the machine from incurring damage in the event of a jam or misfeed.

Locking ETP-Express bushes have replaced mechanical clamping elements in a critical application on PET blow moulding machines. These bushes connect the lever arms that open and close the moulds, allowing slip on the shaft if a preform or bottle becomes jammed. This avoids the machine form being damaged and reduces downtime. Resetting is a quick and simple process compared to the old method that required seven screws to be tightened to a specified torque in a mechanical clamping bush.

The ETP-Express bushes, which are available in the UK from Techdrives, are self-contained units that connect shafts to hubs without keyways. A single radial fixing screw pressurises an internal chamber and expands the walls, gripping the hub and shaft. Accurate positioning both radially and axially is easy while the screw is tightened. Once the screw reaches a travel stop, the bush is set and full torque is transmitted by friction evenly over the surfaces. Up to 1000 mountings/dismountings are possible.

Blow-moulded PET (polyethylene terephthalate) bottles are widely and increasingly used for beverages because they are light, 'unbreakable,' stable and taste-free. PET is also 100 per cent recyclable so it is an environmentally friendly material. Blow moulding machines start with preheated preforms that are transported by conveyors and feed wheels into the blow moulds. Depending on the machine type, there can be from four to 36 of these blow moulds on a rotating assembly. Materials used are mostly aluminium to reduce inertia and achieve higher speeds - up to 72,000 bottles can be processed per hour.

Controlled slippage

Techdrives says that the ETP-Express shaft-to-hub connection is unique in concept and construction. Standard models are available from stock for shafts 15-100mm and full information is available on the Techdrives website. Follow the link for more information and a short movie about ETP-Express locking bushes.

* [See also these application stories: Quick-locking bushes provide for rapid shaft/hub adjustments and Locking bush is quick to release for machine cleaning - Ed]

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Lenze Selection (a Division of Lenze Ltd)

6 Abbey Court Road

Priory Business Park

MK44 3WH

UNITED KINGDOM

+44 (0)1234 753201