Posted to News on 5th Jul 2021, 09:07

Locking on to machining benefits

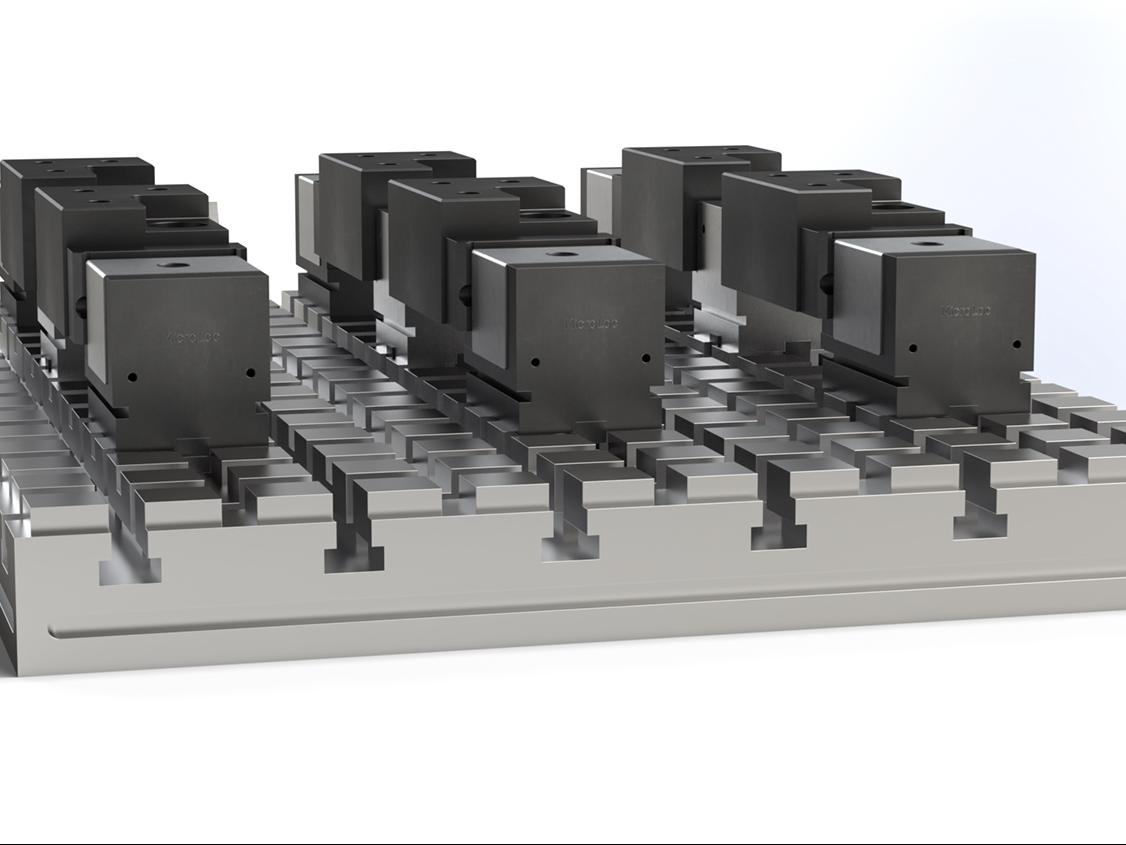

WDS Components MicroLoc System offers expandable means of clamping parts

WDS Components is offering a flexible method of holding metal work pieces for machining that removes the need for multiple, individual fixtures.

The MicroLoc System is an expandable means of clamping parts relative to known datum positions. Reducing the cost of procuring new, additional work holding pieces, MicroLoc can also increase the speed of machine set-up.

Where hundreds of individual fixture pieces would normally be required to machine new designs, MicroLoc’s modular system can significantly reduce cost and save time in procurement, states the company. “As a result of the system’s flexibility, it’s also a rapid and cost-effective way of machining prototypes or one-off items.”

Designed for milling machines and machining centres, the MicroLoc system clamps metal work pieces with a modular approach and can be used across vertical, horizontal or multiple-axis machines. Including a base plate with t-slots, clamping units are inserted relative to a known datum position to securely hold square, rectangular, round or irregular shaped parts. Clamping like a vice, MicroLoc can rotate base clamping elements through 90 or 180 degrees, giving wide positional flexibility.

Machine set-up speed stepped up

MicroLoc clamping designs can be recorded and reproduced when required in future, increasing the speed of machine set-up. By introducing more than one base plate and set, systems can be used across multiple machines, thus reducing the time in set-up and increasing productivity. This approach also allows operators to work across more than one machine at any one time.

“If you regularly make new parts, with a coinciding requirement for new machining fixtures, MicroLoc can save significant cost for future designs and prototypes,” says John Marshall, technical manager, WDS. “By using two or more sets together, with one set used on the current machine and the second set ready in place on the next machine, set-up time is reduced, giving faster productivity.”

WDS stocks the full MicroLoc range, including base plate t-slot pitches of 50, 60, 75 and 100 mm. The torque lock, quickly fastened by hex key, applies to a variety of jaw styles, including aluminium soft jaws, as well as hardened steel jaws, which clamp components across X, Y and Z axes. Jaws are ground to ±10 microns relative to the tenon keys and machine baseplates are produced to a similar tolerance over one metre, giving a system repeatability accuracy of ±25 microns.

Richardshaw Road, Grangefield Industrial Estate

Pudsey

LS28 6LE

UNITED KINGDOM

0845 606 6677