Posted to News on 8th Jan 2012, 21:27

Low-cost H series linear actuators are versatile for automation

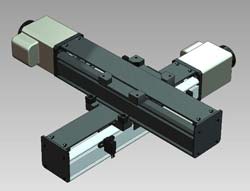

Heason Technology's new H series linear actuators are designed for positioning applications in automated manufacturing and test equipment where the requirements are for cost-competitive products with good performance and versatility. With a choice of seven travel ranges from 25mm to 300mm, commercial- or precision-grade positioning options, and either integrated or separate stepper motor/drive combinations, the H series actuators feature a 'smart' modular design that provides versatile mounting for XY, XYZ and gantry systems, as well as telescopically arranged linear axes for extended Z-axis travel.

H series actuators are based on extruded profile housings with T-slots that facilitate multi-axis actuator mounting, optional limit switches and customer fixtures. A fixed cover plate provides additional protection and is arranged to allow unrestricted carriage travel. The carriage, which may be moving or fixed, is supported by a sturdy linear guide bearing for high rigidity, and a choice of commercial- or precision-grade lead screws is offered to suit application performance and budget requirements. A flexible coupling and anti-backlash nut arrangement guarantees high stiffness with repeatability stated at 0.2 microns for the commercial-grade option and 0.1 microns for the precision-grade version.

Extremely compact multi-axis configurations are possible using Heason Technology's recommended DSMS series stepper motors, which have integrated microstepping drives for much reduced system wiring. With up to 51,200 steps/rev, the maximum positioning resolution is 2 microns with traverse speeds to 170mm/s. Separate motor and microstepping drive combinations are available that can include through shafts for rear-mounted manual knobs - or stages may be fully manually driven.

Customised assemblies

Heason Technology can provide fully customised systems based on the H series linear actuators using its in-house design service. Bespoke options can include encoders for position verification or servomotor-driven systems, alternative pitch lead screws or ball screws, and chain-type cable management.

Motion controllers suited to the H series linear actuators include Baldor's NextMove-ESB-2 panel-mount motion controller. With up to four axes of stepper or servo control, digital and analogue I/O, memory and optional HMI interfacing, the controller features the widely used Mint multitasking Basic programming - or the controllers may be programmed with embedded C or ActiveX components for host controlled applications. The ESB-2 includes simple to advanced motion control capabilities, from point-to-point axis moves to interpolated compound moves that are synchronised with I/O events or external encoders. The controller can work as a standalone machine controller or with PLCs and other PC-based machine control systems.

Follow the link for more information about Heason's H series linear actuators.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Motion Solutions Centre

Spring Copse Business Park

RH13 0SZ

UNITED KINGDOM

+44 (0)1403 792300