Posted to News on 28th Aug 2007, 19:32

Low-cost slat conveyor is quiet, fast and low maintenance

An innovative new conveyor system from Autarky Automation is claimed to reduce factory noise levels by up to 25 per cent in comparison with conventional slat conveyors, thereby helping manufacturing, process and packaging companies comply with the latest Control of Noise at Work Regulations. Just as importantly, the new conveyor system runs at up to 80m/minute, requires only minimal maintenance and is available at much lower cost than many of the existing market leading models.

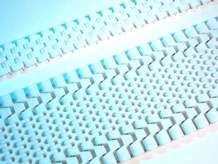

The new conveyor system is called Stretch Line SL and incorporates a specially developed modular belt with robust plastic interlocking finger-shaped sections that are connected by pin hinges. This simple yet effective arrangement offers a high load carrying capacity of up to 200kg, is flexible, tough, lightweight (just 1.0kg/m) and is simple to install and maintain.

Autarky Automation says the innovative design of the Stretch Line SL belt system eliminates the hunting effect normally associated with traditional conveyor chains as they compress and expand; this is one of the main sources of conveyor noise, especially where chains pass around drive or idler wheels. Although this effect can be minimised by the use of catenary mechanisms, noise levels still remain high, typically exceeding 76dB(A) at 40m/minute. In comparison, noise levels from the new Stretch Line SL conveyor are just 67dB(A) at 40m/minute, rising to 75dB(A) at the maximum rated speed of 80m/minute.

Safety features

Noise levels are reduced still further both by the use of specially developed belt drive and idler sections, with extended wear and sliding strips, and extruded aluminium profiles designed to guide and fully capture the belt; this also helps to eliminate the risk of damage to the belt and improves operator safety.

Operator safety is also improved where the belt has to turn horizontally or vertically, as the interlocking belt fingers do not protrude or create open joints that could otherwise form pinch or trap points. Additionally, unlike traditional slat conveyors that generally stretch in the weeks following installation as they bed-in, requiring links to be removed at additional cost, the finger design of the Stretch Line SL means that any adjustments can be made during commissioning without the need for subsequent downtime.

The Stretch Line SL conveyor system is manufactured in Germany by Schüco, for which Autarky Automation is the exclusive UK distributor, and is available with a wide range of drive, guide and support components. Autarky Automation also provides a full design, installation, commissioning and technical support service.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>