Posted to News on 11th Jun 2021, 08:58

Low-noise sensing solutions for wind turbines

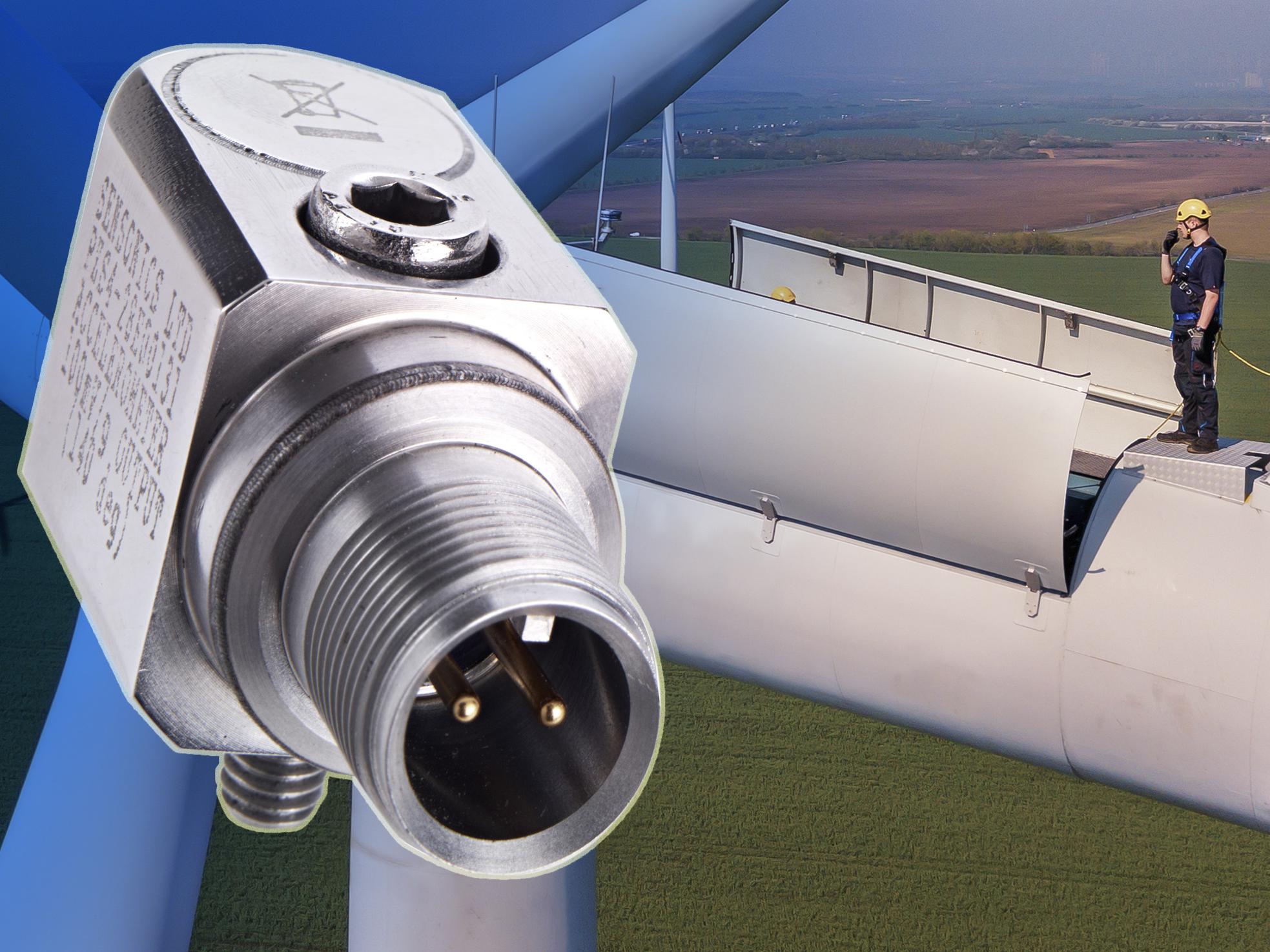

Sensonics demonstrates expertise in performance criteria for accelerometers used at low frequencies

The capabilities and sophistication of today’s industrial machine sensors means they are an integral part of most manufacturing systems, such as those used for critical condition monitoring applications. Their performance continues to be developed and improved, driven largely by the rapid expansion and application of digital technologies. Accelerometers are one example and, while there is a wide choice of options, not all industrial accelerometers are the same.

Condition monitoring specialist Sensonics has been developing these types of sensors for over 40 years “and vibration sensing on wind turbines is one application where they are now recognised as a world leader in providing low noise sensing solutions”, says the company.

Complex algorithms

Condition monitoring on critical machinery can involve complex algorithms, extracting fault vibration frequencies from a spectrum of signals, with early detection being a key requirement. “As a result of its experience in the design and manufacture of piezo-electric seismometers, initially for seismic monitoring systems, Sensonics has unparalleled experience in understanding the performance criteria for accelerometers used at low frequencies.”

Its piezo-electric seismometers are acknowledged as being very high output accelerometers, providing up to 50V/g low frequency measurements down to 0.1Hz and ultra-low noise floor. “This expertise has placed Sensonics in the unique position of being able to part transfer and apply this knowledge to the established range of PZS accelerometers, which are regarded as ‘best-in-class’ for low noise performance for wind turbine applications, critical when carrying out vibration analysis from a condition monitoring system [CMS], it adds.

Effective monitoring

The proven shear mode constructed PZS accelerometer series has been supplied for numerous wind turbine applications over the past 10 years and the ongoing enhancement of the range provides a frequency response down to 0.1Hz. This permits effective monitoring of both the wind turbine main shaft and input gearbox bearings below rotational speeds of 20RPM, which has become increasingly important for today’s wind turbine condition monitoring systems.

As with any rotating machinery in a critical application, the monitoring of vibration plays an effective role in the early detection of mechanical problems on the machine. The PZS accelerometer response is suitable for measuring vibration across the full wind turbine machine train, not only the low frequency front end, but also the planetary gearbox stages and generator, providing an upper frequency response in excess of 10kHz.

Successful implementation factors

The shear mode sensor is electrically and thermally isolated from the main accelerometer housing, minimising the effect of electrical interference on the measured signal and the impact of thermal changes, which can result in base strain effects. These are key factors to the successful implementation of low frequency accelerometers.

Available in straight and side exit mechanical configurations, with mounting threads to suit most applications, the PZS is supplied with either a 2-pin connector or integral cable, offering protection up to IP68.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>