Posted to News on 15th Nov 2011, 12:27

Machine control technology quadruples throughout

Baldor's servo, stepper and motion control technologies have enabled Techserv Cutting Systems to develop a flue pipe cutting system that virtually quadruples throughout for a flue manufacturer.

Techserv Cutting Systems, a specialist manufacturer of CNC profile cutting systems, has developed an innovative plasma cutting machine for flue pipes. Advanced interpolated motion of the cutting system dramatically increases production throughput, with control coming from an economic real-time machine control module from Baldor.

Capable of cutting aluminium and stainless steel flue pipes at any angle, as well as holes of any shape or size, the plasma tube cutter automates this aspect of manufacturing. Until now, for example, elbow pipes have traditionally been produced by first cutting complex shapes from flat metal sheet, which are then rolled and welded before assembly. This multi-stage fabrication process involves considerable movement of workpieces around the factory and is very time-consuming.

However, the new cutter dispenses with the need to pre-cut complex shapes. Instead, the flat metal sheet is first rolled into a tube and seam welded, then each tube is successively loaded into the machine. The entire cutting operation is handled autonomously; a simple angled cut takes a matter of seconds. Cutting the angled end pieces for an elbow pipe and then assembling them - a task that previously took about 15 minutes in total - can now be accomplished in around 4 minutes.

Servos and steppers

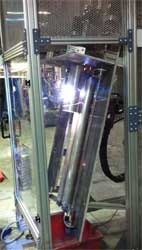

The tube being cut is mounted in the machine with its top end held in a rotating pneumatically-driven clutch assembly. The plasma cutting torch is moved up and down as the tube rotates, at a rate that determines the severance angle or the size and shape of the hole being cut. Both the main rotational axis and the plasma torch height axis are powered by Baldor BSM series AC brushless servomotors driven by Baldor MicroFlex digital servo drives, and interpolation achieves a constant cutting rate regardless of the profile of the cut or tube diameter. The machine can handle a wide range of tube diameters, from 90-350mm, with wall thicknesses up to 1.5mm.

In addition, the tube cutter uses three Baldor stepper motors. Two of these control the position of a pair of guide rollers, which support the tube during the cutting process and are driven closer together or further apart, depending on the tube diameter. They also move aside automatically during the tube reload operation to facilitate operator access. The third stepper-driven axis dynamically varies the distance between the plasma torch head and the wall of the tube during the cutting process to provide optimum performance.

Motion control

All five electrical axes are controlled by a Baldor NextMove ESB-2, a compact real-time machine control module that receives commands direct from an onboard PC-based CNC system developed by Techserv specifically for tube profile cutting applications. The CNC software runs under Windows XP, with all operator information presented on a large touch-sensitive, full-colour HMI.

Baldor's NextMove controller is said to be particularly cost-effective for applications such as this; it provides all the control functions for the machine's five servo and stepper motion control axes, with even the base model capable of accommodating a further two axes if required for future machine variants. The controller also features extensive built-in I/O capabilities, with more expansion options, to provide an economic machine control platform.

Techserv's Technical Director, Mike Cowley, states: "Baldor's high-level Mint programming language helps us to develop motion control programs for custom applications like this very quickly. Integrating the NextMove controller with our front-end CNC system was also straightforward because it uses the same API naming conventions as ActiveX commands. As we need to change the scaling and speed of the machine's servo axes on-the-fly in order to maintain a constant cutting rate, the controller's fast interpolation capabilities provide an important advantage. And as with many of our plasma cutting machines, we find that Mint's 'Hold-To-Analog' command is especially useful, since it allows us to handle real-time control of the plasma arc entirely within the NextMove controller. We continuously monitor the arc voltage and the software interprets this analog value to automatically adjust the distance between the torch and the tube wall, thereby maintaining the constant plasma characteristics needed to ensure optimum cutting performance."

The new plasma cutter was developed for Flues & Flashings, a company that specialises in the production of ducting products for the domestic and commercial heating markets. Gary Watkins, Works Manager at Flues & Flashings, comments: "The performance of the plasma tube cutter is superb. Changing the process so that we are preforming the tubes before cutting them, instead of cutting complex shapes from flat metal sheets, has enabled us to virtually quadruple manufacturing throughput. In fact, we were able to produce six months' stock during the first two weeks of machine operation."

A video of Techserv's plasma tube cutter can be viewed at: www.youtube.com/watch?v=_0nY2rZaAvQ or follow the links for more information about the NextMove ESB-2 machine control module and MicroFlex digital servo drives.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>