Posted to News on 15th Oct 2020, 08:55

Machine enclosures are rarely a one-size-fits-all solution

They are as distinctive as the equipment they protect. In this article, Rittal's Product Manager Emma Ryde makes the case for Smart enclosures

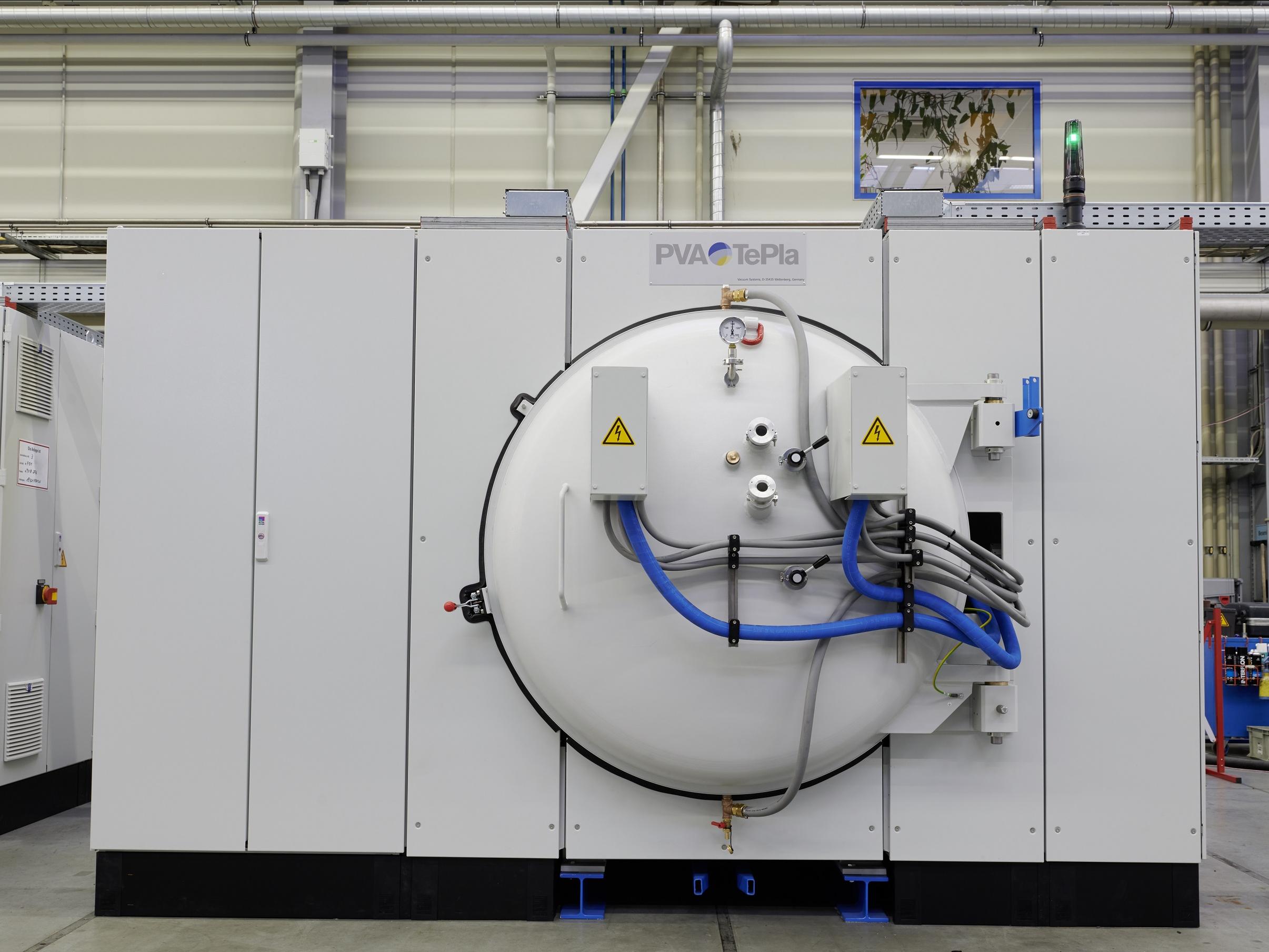

Machine enclosures are rarely a one-size-fits-all solution; they are as distinctive as the equipment they protect. In fact, they are often custom-designed and made-to-measure: a time-intensive and often expensive option. However, there is an alternative, as illustrated by PVA TePla, a vacuum specialist company specialising in high-temperature and plasma process technology. It employs standardised housings to protect its systems, and not just for reasons of efficiency.

Let’s be honest, enclosures are not generally front and centre in people’s minds

They are typically in the background, placed behind production machines or on remote platforms in factory buildings. Even the largest enclosures are not usually offered star billing; they are workhorses, providing basic support services. They need to perform, but not grab the headlines. Nothing more is expected of them. Their mission is to ensure reliable control and switching functions for industrial plant and machinery. They protect people and technology, and create an ideal environment for electrical and electronic components that help to deliver stable manufacturing processes.

In the engineering industry, however, enclosures have a more prominent, high-profile role to play. They appear not just behind machines, but alongside them - or even as an integral part of them – and they play a rather different role. With the help of control displays on doors and side panels, or by means of connected control and support arm systems, they act as assistants to the (human) machine operator.

That is certainly the case for PVA TePla, a maker of specialist machinery.

At the company’s large and light-filled factory in Wettenberg near the city of Giessen, its enclosures almost overshadow the equipment they serve. They are positioned at the very front and dominate the overall appearance of the machines. The vacuum technology specialist has employed Rittal enclosures for many years (including them as a way of fully encapsulating its MOV 743 heat-treatment furnace) and since 2019 it has deployed the new VX25 system portfolio.

“The Rittal enclosure system allows us to build manufacturing equipment that boasts an attractive product design; it does not have the appearance of industry or mass production. They are products that would not look out of place in your living room,” explains Martin Kaiser, Managing Director of PVA Control.

A Better Look With Lower Costs

“The idea to employ enclosures to house our equipment came to us when we discovered, by accident, that a long-established customer had asked a metal-working expert to create a ‘package’ for our machines that would make them suitable for presentation in a showroom,” states Kaiser.

For Kaiser, this was an opportunity to develop an entirely new housing concept. The proposal was to take the design of an enclosure that had always been an integral part of the plant and apply it to the entire plant and all its housing. “We were and remain convinced that housing a machine with a series of adjacent enclosures creates a highly attractive, consistent look-and-feel that also aligns visually with other switchgear units,” emphasises Kaiser.

He adds, “We simply tried it out and were pleasantly surprised in two ways: first, because it worked very well from a technical perspective, and second, because the enclosure-based approach was about half the cost of purchasing a custom-built housing from an external specialist.”

Quicker Assembly & Installation

Faster assembly and installation translate directly into cost savings for the company. "We generally have the housing complete in two days,” reports Kaiser. For PVA Control, conventional housing solutions are usually custom-built by an external specialist, a slow and expensive process. It includes the positioning of posts, the attachment of panels chosen in line with the specific use case, and the application of a powder coating.

The company says it can now reap the rewards of its new modular enclosure system, which not only improves the installation speed, it also delivers greater flexibility. Once the mechanical design of the plant is complete, the next step is to define the appearance of the system as a whole – specifically, the outer dimensions and therefore the size of the housing.

To this end, PVA Control uses suitable standard components with Rittal pitch patterns for enclosures 1000mm and 800mm wide. The aim is to create a continuous housing with side panels and doors wherever access is needed, for example for maintenance. The housing for the MOV 743 plant comprises a total of 12 individual enclosures and the benefits of this new approach are considerable. Ordering enclosures and accessories from Rittal’s catalogue or online shop is quick and easy. Plus, using attractively priced standard products cuts costs and the enclosures offer multiple assembly and installation options.

“The VX25 accessories and frame profiles mean we can install components virtually anywhere, allowing us to easily attach, for instance, pipe brackets or cable clamps. We are pleased to have any opportunity to flexibly add something,” explains Kaiser. Moreover, the simple machining of sheet metal for flat parts such as doors and side panels – for example, when drilling holes or creating cut-outs for fan-and-filter units – is a real accelerator.

“We simply place the flat part in the Rittal Perforex BC machining centre, and it drills the holes automatically,” adds Kaiser. This means the sheet metal elements do not have to be sourced from an external supplier or machined manually which can be laborious and inexact. Furthermore, the enclosure technology can be integrated into the development of the plant itself; in other words, the housing can “expand” as the amount of equipment “expands”. Once the plant has been pre-assembled, additional enclosures are easy to add-on, for example, when a cable duct needs to be routed along the top of the housing. “If this takes too much time, it is a disaster, because the team cannot make progress with their work tasks,” Kaiser explains.

Assembly and installation made simple

The enclosures also streamline the installation and removal of doors and side panels. Once the equipment is placed within the enclosure frames, the doors and side panels can be quickly and easily added during the customer acceptance process. VX25 enclosures are designed so that this can be done just one person without any tools; the door is simply placed on its hinges.

“The installation of doors and side panels for this system is typically complete within an hour,” Kaiser advises. Without this modularity, assembling and dismantling the entire plant would be considerably more difficult for PVA TePla. “The individual parts are interchangeable. It does not matter if, later at the customer site, a door is hung in its original location or on the other side,” emphasises Kaiser.

Standardisation gives the engineering company a great deal of freedom, and the global availability of VX25 components is an added bonus if any repairs are needed. As for the VX25 features he finds most impressive, Martin Kaiser summarises: “It’s the 130-degree hinges, the robust base gland plates, the many possibilities created by the new plinth system, and the fact that the enclosure system as a whole requires fewer accessories and less storage space – and therefore has associated cost benefits.”

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Braithwell Way, Hellaby Industrial Estate

Hellaby

S66 8QY

UNITED KINGDOM

+44 (0)1709 704000