Posted to News on 24th Mar 2010, 12:31

Machine guard switches - a wider range from Pilz

Pilz now supplies a far wider range of machine guard switches than before, offering machine builders and those maintaining or upgrading machinery the opportunity to buy these high-quality yet cost-effective products from a supplier that is renowned for its machinery safety expertise.

Increasing automation in the process and control industry means that the demands on machine safety are also rising. Aspects of process safety, availability and cost-effectiveness must all be reconciled.

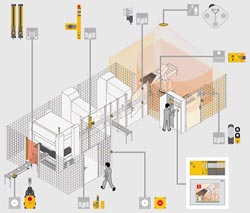

Safety guards and gates for protecting personnel against hazardous movements on plant and machinery, as well as hazards from ejected material, can be monitored by a wide range of safety sensors and switches available from Pilz; these take into account not only safety-related issues but economic considerations too. The choice of safety interlock switch will depend partly on the machine and partly on the safety-related requirements.

New guard styles

To give operating personnel as much freedom as is reasonable, lift guards and rolling shutter-like constructions have become increasingly popular in addition to classic hinged or sliding guards. The fact that plant and machinery are becoming ever more compact means that the sensor technologies protecting these safety gates has had to adapt accordingly.

Safety and productivity are important but, if user-friendliness lags too far behind, it is not unusual for operators and maintenance personnel to be tempted to manipulate or override safety equipment. For this reason designers also have the task of identifying potential reasons why devices might be manipulated and to eliminate these in advance at the machine's development stage.

Non-contact switches

Pilz PSENmag non-contact magnetic safety switches are increasingly being used on safety gates - in accordance with the risk classification - rather than mechanical safety gate switches or roller switches. The benefits of non-contact switches are obvious: less work is required for adjustment and the service life can be significantly higher.

Alternatively, PSENcode coded non-contact safety switches with RFID transponder technology are becoming more popular but are no less established. They combine all the benefits of non-contact safety switches with high security against manipulation thanks to individual actuator coding. Built-in 'intelligence' means it is possible to achieve a high level of safety with just one switch connected to the appropriate evaluation device.

Locking devices

Safety-related guard locking devices are used where cramped conditions mean that safety guards have to be located close to the hazardous movement. In this case, safety gates not only have to be safely monitored but securely locked as well. A mechanical guard locking device prevents the gate from being opened.

Relatively new to the market, the PSENslock guard locking devices feature integrated, safe position monitoring based on a magnetic action principle. They combine secure safety gate monitoring with a non-contact magnetic interlock. Compact and sealed to IP67, these devices are suitable for use in harsh environments.

Nonetheless, today the PSENmech mechanical safety gate switches are still widely used for simple safety gate applications where there is no increased requirement for protection against tampering. Mechanical safety switches use increased extraction force on the actuator to prevent a safety gate, cover or flap from being opened unintentionally.

PSENbolt safety bolts are particularly suitable for safety gates that are difficult to adjust or in areas where safety gates are often opened and closed, as the actuator is mechanically guided into the switch actuator head. This guarantees that the actuator is inserted correctly into the safety switch when the guard is closed. It therefore provides mechanical protection for the switch.

Hinge switches

For hinged gates and flaps, PSENhinge hinge switches are available as a space-saving alternative. These offer the benefit of high availability, as they are manipulation-proof, being concealed within the hinge. Designed as one functional and installation unit, hinge switches offer a high level of flexibility in installation, connection and adjustment. They may be mounted on the right or left, and the switching point can be set and readjusted anywhere between 0 and 270 degrees.

PSENrope safety cable pull switches are typically used on accessible sides of conveyors or machines. In contrast to emergency stop pushbuttons (installed at intervals), with which the emergency stop signal can only be generated at the device itself, the safety cable pull switch makes it possible to generate the signal at any point in a section. Safety cable pull switches are suitable for use in both indoor as well as outdoor applications. Depending on the type of cable pull switch, a span of up to 75m can be safeguarded. These safety cable pull switches are equipped with an integrated emergency stop button that can be pressed in hazardous situations.

PSENopt safety light curtains are used to safeguard access to danger points, where the production process requires active intervention. An invisible protected field of infrared beams protects these zones. If a light beam is broken, it immediately triggers a safe shutdown command. In this way personnel can be protected from injury, safely and effectively, but without causing an obstruction. Muting, blanking and/or cascading offer a range of possibilities for optimum incorporation of optoelectronic protective devices on plant and machinery in all industries. Thanks to compact dimensions, simple installation and optimum performance, light curtain devices are particularly suitable for applications in areas where operator intervention is required as part of each machine cycle, such as insertion work, or for the infeed and/or outfeed of material.

Follow the links above to find out more about specific products.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>