Posted to News on 12th Nov 2021, 08:57

Material application and curing process in one

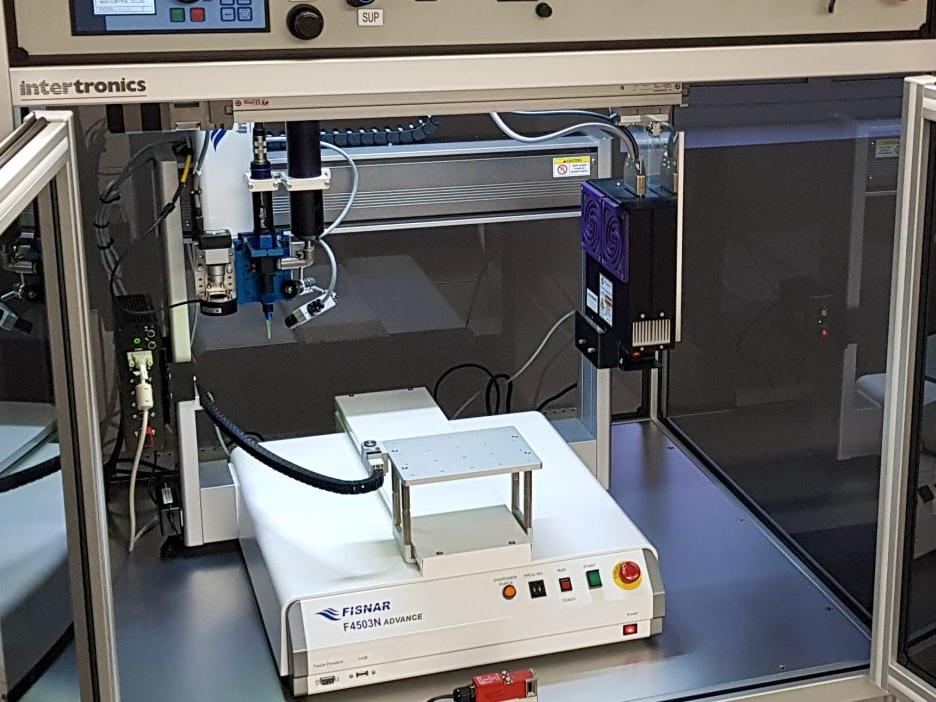

Robotic dispensing with vision system and LED UV light curing

Shown here is an example of Intertronics’ archytas series robot integration capability.

The robotic dispensing system and UV light curing offers a combined material application and curing process in one compact machine.

Comprising a volumetric preeflow eco-PEN mounted on a Fisnar F4000 ADVANCE robot with CCD vision system, and a Phoseon LED UV curing flood lamp on a linear drive, “this automated system applies UV-curable adhesive, sealant, coating or other material with a high level of accuracy and precision”, says Intertronics.

“The UV curing flood lamp is then automatically actuated and it passes over the parts, effecting a complete and fast cure of the material.”

Safety in operation

Integrated controls allow operation from the safety of outside the enclosure, while the enclosure itself offers smoked glass for UV light safety and a dead switch, which activates, if the doors are opened during operation.

In this instance, customers’ material is packaged in 310ml cartridges, so the preeflow eco-PEN is fed from a 310ml cartridge retainer, but this system could easily be customised to support material in syringes, cartridges or bulk packaging, adds Intertronics.