Posted to News on 1st Apr 2021, 09:10

Materials store for laser machines boosts productivity

New store enables all TRUMPF 2D flatbed laser machines to work autonomously for up to 11 hours

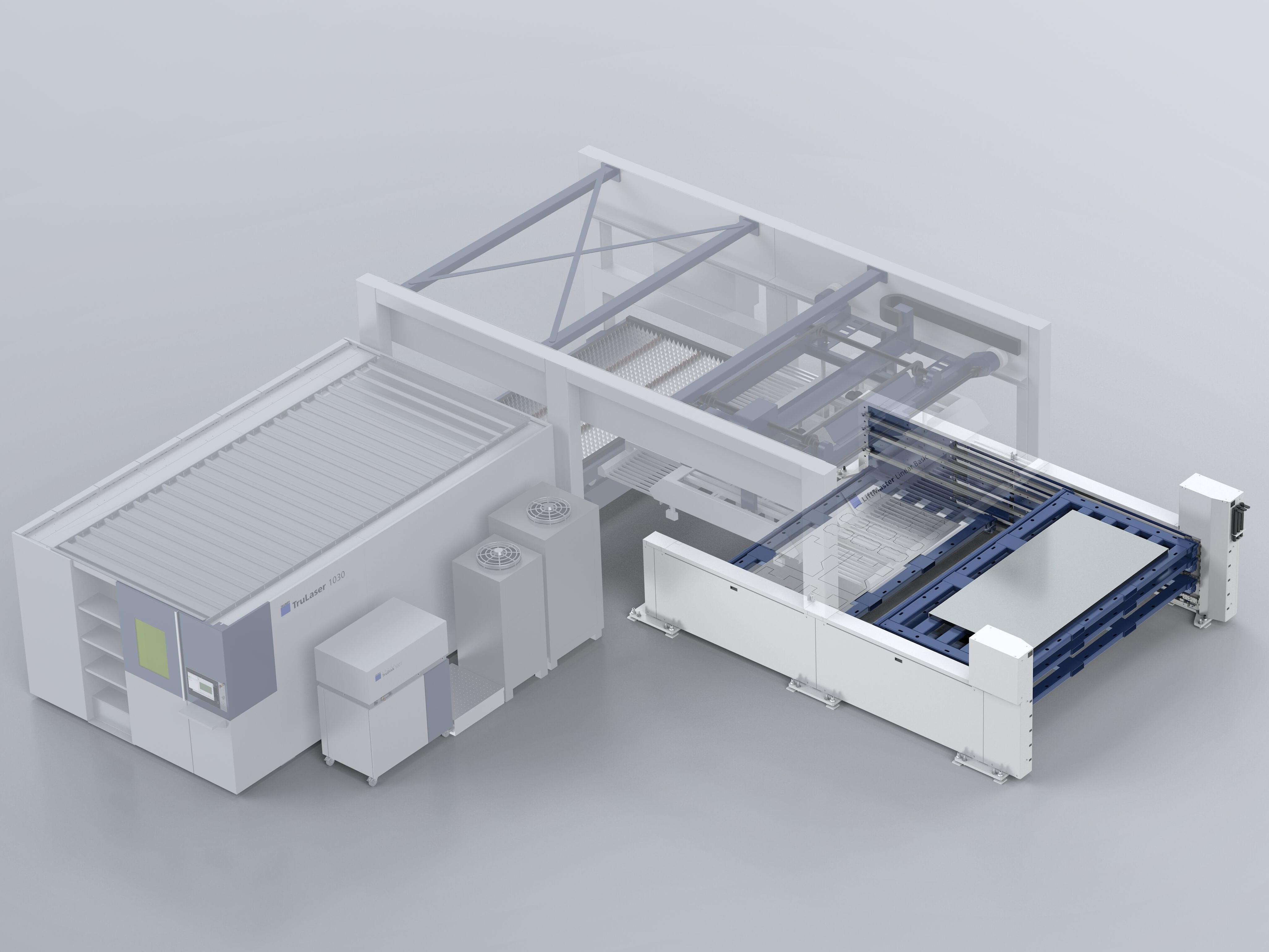

The materials store from TRUMPF is available in various configurations with different numbers of storage compartments. Combined with the LiftMaster Linear Basic automation solution, it automatically loads raw materials into TruLaser machines, saving workers from having to manually manoeuvre the heavy metal sheets into the machine and the storage compartments can also be used to store sheets after cutting.

The solution allows companies to work through the night without any workers on the shop floor, making better use of their machine capacity and improving productivity.

Retrofitting machinery

The materials store is described as easy to use and requiring no additional software. The automation solution also takes up little space. “Our new materials store is primarily aimed at customers who are just starting out on their automation journey in sheet metal fabrication – for example, those who wish to incorporate an additional automated shift,” says TRUMPF product manager Stefan Häußermann. “In many cases, we can help them achieve that by simply retrofitting their existing machinery.”

Customers can choose between materials stores with three, four or five storage compartments. This also offers the option of placing the raw material in the materials store, together with its wooden pallet. This saves the operator from having to laboriously unload the metal sheets from the wooden pallet by hand or with a forklift truck.

Separate tower

TRUMPF also offers a separate storage tower for the materials store. If a machine only works its way through part of the stack of unprocessed material, the remainder of the stack can be taken on its pallet to the storage tower where it can be held until needed again. This helps keep stored materials organised and allows the machine to switch to new materials faster.

www.trumpf.com

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>