Posted to News on 17th Feb 2021, 09:15

Measurement gauge closes the gap

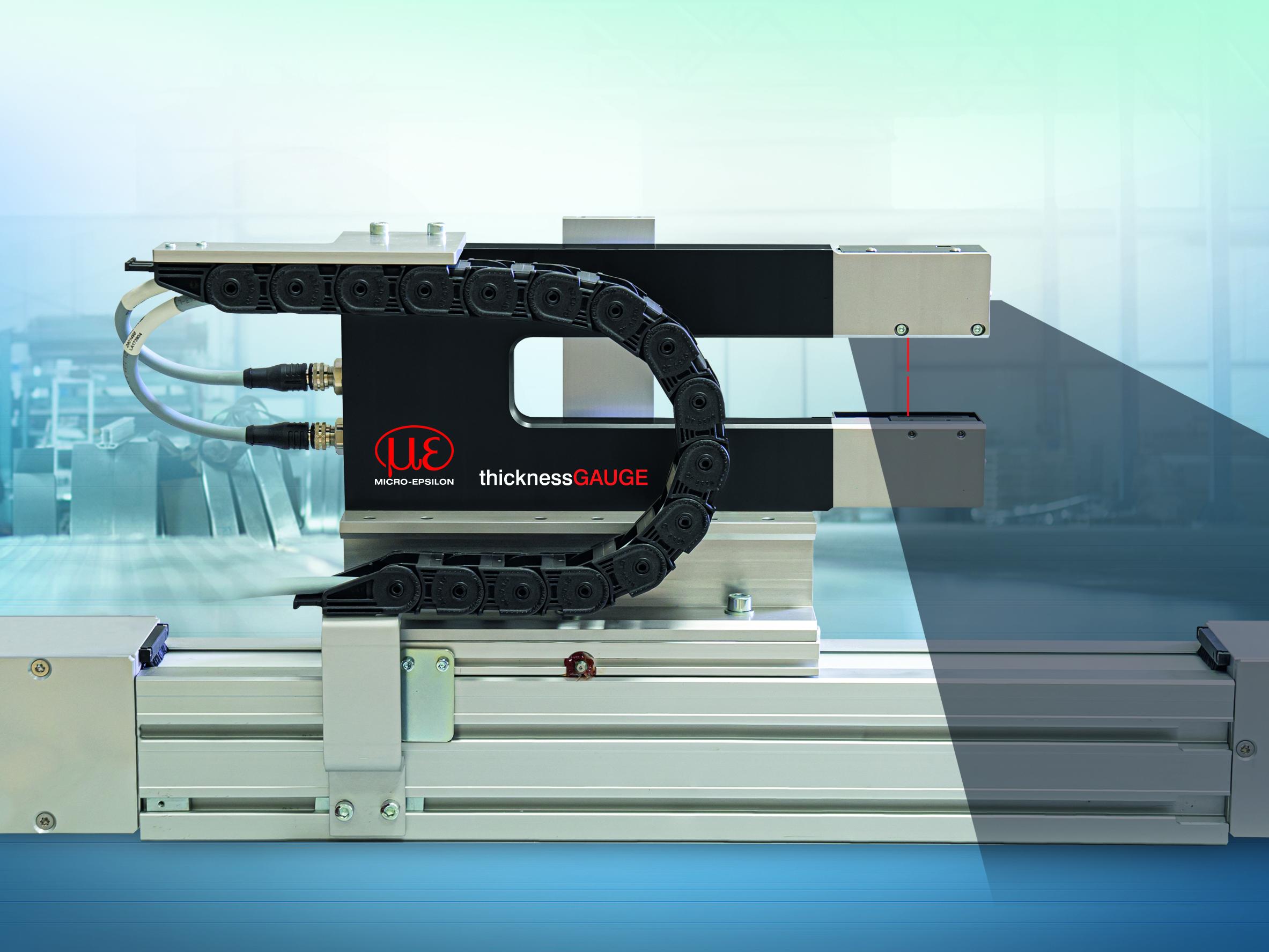

Out-of-the-box solution for thickness gauging and quality control unwrapped

A new compact thickness measurement gauge from precision sensor supplier Micro-Epsilon is said to close the gap between simple thickness sensor solutions and high-cost dedicated systems for strip, plate and sheet materials up to 25mm thick.

The system, says the company, offers precise measurement from ± 0.25µm and “fills the gap that currently exists in the market between basic thickness sensors and higher cost, dedicated inline thickness measurement systems”.

The new thicknessGAUGE measurement system is suitable for both offline and inline thickness gauging, and is available in several versions that use one of three different sensor types – laser triangulation, laser profile or confocal chromatic sensors. “The flexibility of technology selection from Micro-Epsilon’s own portfolio of sensors ensures optimum results are achieved, based on the surface type, material to be measured and the performance requirements of each customer.” The system also offers different measuring ranges and measuring widths to suit a wide range of applications.

‘Difference’ principle

The fully assembled thicknessGAUGE system comprises a stable frame on which two optical distance sensors are fixed, which measure the thickness of the target material using the ‘difference’ principle. Before being shipped to the customer, the sensors are perfectly aligned to each other on the frame and factory calibrated for the application.

The specific linearisation of the sensors in the frame means that the complete system accuracy is better than the individual sensors combined. The entire system is powered via a 24V power source, which makes the installation and integration work as simple as possible, adds Micro-Epsilon.

The thicknessGAUGE is mounted on a linear axis with electromechanical drive that moves the sensor system from the ‘home/park’ position to the required measuring position. Depending on the application requirements, the system can be operated in traversing mode, scanning back and forth continuously, or in fixed track mode where a specific point, often the centreline, is taken for gauge control. The system can also be set to edge mode for control of the material edge thickness.

thicknessGAUGE is equipped with an automatic calibration unit, consisting of a certified gauge block that is measured periodically as part of the traversing process. The use of a gauge block as part of the system ensures optimum accuracy is maintained, and accounts for the effects of fluctuating temperatures and changes in the distance of the measurement gap. “The calibration cycles are individually adjustable to the customers’ needs, take just seconds to complete and being part of the gauge means the process never has to stop.”

Analysis and control software

All thicknessGAUGE systems are supplied with a multi-touch panel industrial PC that is pre-installed with the thicknessCONTROL software package from Micro-Epsilon. This is the same software used in the high-end measurement systems and provides touch gesture control similar to that of modern smart phones. The measured process values can be displayed in multiple ways, including simple large values of thickness, cross profiles and length trends or combinations of each.

The different measurement modes, such as fixed track thickness measurement at any position, traversing measurement of the thickness cross profile, and 3 or 5 track measurement of longitudinal thickness trends, can be selected. Full SPC data of the measurements is available and an automated verification of the system’s capability can be completed by the customer themselves.

Other features for documentation and process control include an article database, production archive, statistical evaluations, as well as limit value monitoring with ‘return back to production’ using (optional) digital fieldbus interfaces.

Continuous measurement

Glenn Wedgbrow, business development manager at Micro-Epsilon, comments: “It is often the case that customers will attempt to create simple thickness measurement solutions using individual sensors, without paying attention to the issues of mechanical setup changes, calibration and usability. Whilst the costs at first glance may seem low, this solution typically ends up with an unsatisfactory measurement performance and much more money wasted in attempting to rectify the issues.

"The thicknessGAUGE system removes those concerns, as it is delivered complete and is ideal for inline thickness measurements of any plate production and strip processes to measure the thickness of the materials on a continuous basis.”

The systems are also designed in such a way that they can be used as both initial equipment and for retrofitting to existing facilities. “The compact nature of the thicknessGAUGE makes it ideal for fitting into restricted spaces,” he adds. “Potential applications include the measurement of plastic film, woven materials, wood and ceramics, as well as metal film, strip and plate materials.

"In particular, the new fields of battery production, with its combination of materials for fuel cells and battery film, coated or uncoated, are perfect examples of applications for this type of system.”

No. 1 Shorelines Building

Shore Road

CH41 1AU

UNITED KINGDOM

+44 (0)151 355 6070