Posted to News on 15th Apr 2010, 15:49

Metrology system benefits from confocal displacement sensors

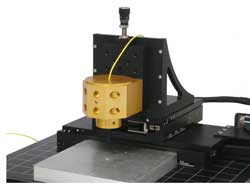

A new non-contact metrology system that provides portable surface profiling, imaging and thickness measurements down to nanometre resolutions is utilising high-precision optoNCDT 2401 confocal displacement sensors from Micro-Epsilon.

Rhombus VS Ltd has recently developed the Hornet3D, a new metrology. The company's team of multi-disciplined engineers has extensive experience in high-accuracy process and motion control, integrated software solutions, parts handling, robotic integration, beam profiling, laser processing, galvanometer scanning and calibration. Hornet3D is is a versatile, modular system that can be customised for specific surface profiling applications. It can be specified with a range of different sensors and cameras, including Micro-Epsilon's optoNCDT 2401 confocal displacement measurement sensor.

Hornet3D comprises an X-Y scanner and stage platform with a modular Z-axis fixture with an integrated sensor. The system is completely scaleable; if required, the sensor or microscope can be easily removed and replaced with an alternative unit, providing flexibility for the user in terms of measurement range and resolution. The stage platform can also be made larger or smaller, depending on the customer's requirements. The Hornet offers resolutions in the X-Y axis down to 0.1um. Micro-Epsilon's optoNCDT 2401 confocal sensor provides a Z-axis resolution down to 10nm and a sampling rate of 0.1-20kHz, depending on the scan parameters.

Furthermore, the system includes Rhombus' integrated Surescan software that enables users to define scan regions and the resolution. 2D false colour maps can be created, as can full 3D animated images, cross-section analyses for sample profiling and measurements, and basic reports. Data can also be exported to third-party software packages, and reports generated.

Best price-performance ratio

Graeme Elliner, Technical Director at Rhombus VS, comments: "Hornet has been in development for over a year now and is continuously being improved. When we were looking for a suitable sensor supplier, the two most important selection criteria for the sensors were spot size and resolution in the Z-axis. Technically, Micro-Epsilon's range of confocal displacement sensors offers the best price-performance ratio on the market.

"We also liked the fact that the optoNCDT 2401 is designed for harsh industrial environments. The optoNCDT 2401 sensor system is at the high end of the market when it comes to confocal displacement technology."

The optoNCDT 2401 confocal chromatic sensor system comprises an LED-based controller and a sensor, connected by a fibre optic cable up to 50m long. The system has no moving parts and is therefore wear-free. There are three choices of sensor designs available: the 2400, 2401 and 2403 series, which cover more than 24 different measurement ranges as standard. In addition, what is described as the world's smallest confocal sensor, the 2402 series, has a diameter of just 4mm and typical lengths of 40-50mm. ATEX-certified versions are also available.

Micro-Epsilon describes the optoNCDT 2401 as a compact sensor with a large stand-off distance that is able to perform one-sided thickness measurement of transparent materials such as glass and plastics, as well as multi-layer surfaces, including substrates and laminates. The sensor offers extremely high spatial resolution for microscopic surface profiling. Spot size diameter is down to 7um and resolution on the 3mm measuring range sensor is 0.12um.

Working relationship

Elliner adds: "All our systems have to measure in microns and so the sensors we select have to support this level of precision. We have built up a very good, two-way working relationship with Micro-Epsilon over the past 12 months. If Micro-Epsilon has a customer with a specific metrology issue, Rhombus may be called in to help devise a complete solution using its systems integration expertise. In the UK market, this type of relationship is key to solving measurement issues for OEMs and end users, who want a full system solution supplied by a single source."

The confocal measurement principle uses polychromatic white light, which is focused onto the target surface using a multi-lens optical system. The lenses are arranged so that the white light is dispersed into a monochromatic light by controlled chromatic aberration. A specific distance to the target is assigned to each wavelength by factory calibration. Only the wavelength that is exactly focused on the target is used for the measurement. This light reflected from the target surface is passed through a confocal aperture onto a spectrometer, which detects and processes the spectral changes.

Extremely high resolutions are possible when using the confocal principle; resolutions in the nanometre range are possible by expanding the colour spectrum. As colour in the focal point is used for distance information, confocal sensors have a very small measuring spot, which also makes measurements on tiny objects possible; even the smallest of scratches on a surface or substrate can be detected reliably.

The beam path of the sensor is compact and concentric, enabling the system to measure inside drilled holes - which is something that other optical measurement methods (such as laser triangulation) find difficult or even impossible to achieve due to the formation of shadows.

Elliner concludes: "Confocal displacement sensors are an excellent fit with our Hornet system, as they are modular in their design. There is one standard controller and interface; only the sensor head needs to be changed. Long cable runs are also possible, so we can solve most application issues. We have used the confocal sensor in a wide range of applications to date, including the surface profiling of tracks in printed circuit boards, measuring the thickness of thin-film solar panels, glass substrates, laser micro-machining, inkjet printing and even wear on hip joints."

Follow the link for more information about Micro-Epsilon's optoNCDT 2401 confocal displacement sensor.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

No. 1 Shorelines Building

Shore Road

CH41 1AU

UNITED KINGDOM

+44 (0)151 355 6070