Posted to News on 26th Feb 2012, 21:34

MiniTec Profile System used for PV test equipment

MiniTec Profile System machine framing and building components are used extensively by IPSOL Energy for the construction of specialist test equipment used to assess photovoltaic cells and modules.

IPSOL Energy provides specialist product test, R&D and consultancy services in clean energy, with a particular emphasis on the rapidly expanding solar photovoltaic (PV) market. From its base in Nottingham, the Company operates what is claimed to be the UK's first and only fully accredited test house for IEC certification of commercial solar panels and offers many other complementary services including PV module performance measurement, environmental evaluation and PV cell characterisation. A strategic partner and a spin-out company from Loughborogh University, IPSOL's Centre of Excellence includes state-of-the-art test and measurement equipment based around MiniTec Profile System machine framing and building components.

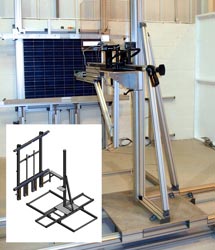

Recently completed IPSOL installations have included MiniTec's structural elements and machine frame hardware for three separate IEC certification tests that each required the flexibility to accommodate a wide assortment of solar panel types and sizes as the Unit Under Test, and to provide a stable structure for various pieces of measurement or test-support equipment.

The projects covered an enclosed 30m3 Soak Room where PV panel performance is measured over long periods under simulated light and environmental conditions, a UV-Degradation test stand that measures a solar panel's resistance to UV exposure, and a Hail Test where 25mm diameter ice balls are projected at the panel to test its ability to withstand such impacts.

Certification

IEC certification not only guarantees high quality and reliability but is also is a requirement where PV modules are being used, for instance, for the UK's Department of Energy and Climate Change and other nations' Feed-in Tariff schemes (FITs) - where investors in small-scale, low-carbon electricity generation are guaranteed payment for the surplus power they generate and export.

From the initial contact, MiniTec worked closely with IPSOL, using its own in-house design service to develop 3D CAD concept drawings for each test stand, incorporating all of the salient information for IPSOL's preferred measurement equipment that would eventually be fitted. IPSoL's CEO, Peter Khoury, states: "From the outset we were impressed with the consultancy that we received from MiniTec. We had a good idea of what was required and gave them sketches to work with, but the attention to detail was particularly pleasing."

Once the order was placed, these concept designs were developed concurrently as IPSOL sourced and supplied third-party components such as UV lamps and lamp holders to MiniTec during pre-assembly to ensure their correct installation and to co-ordinate electrical cabling requirements.

Fast assembly

The flexibility of the MiniTec Profile System allows for rails, hardware and frame construction to be easily adapted to accommodate changes during build. MiniTec's Powerlock fastening system is a fast and effective frame connector that requires only the twist of an Allen key, with no profile pre-machining as found in competitive systems. This makes profile re-use and adaptation possible with minimum cost and effort - and also contributes to MiniTec enjoying what is claimed to be the fastest assembly time for all the available framing systems on the market today.

Practically all of the frame construction parts of the three IPSOL systems are built from standard MiniTec components, including a novel hand-operated hydraulic lift with four parallel cylinders that allows balanced vertical positioning of the large solar panels for the Hail Test. Manually operated slideways with locking mechanisms are used elsewhere to position panels or test equipment in horizontal and vertical planes, with Z-axis positioning aided by a chain counterbalance arrangement that is integrated in the vertical column. The Soak Room's Alumetal panels are finished in a matt black with tinted Perspex door panels. IPSOL has fitted a laser sensor measurement system to the Hail and UV test stands to enable precise and repeatable manual positioning for the various tests.

IPSOL's Centre of Excellence facility has taken full advantage of global needs for PV testing, offering realistic product development and certification timescales in comparison to test houses in Germany, the USA and the Far East. However, managers remain very conscious that the quality and aesthetic presentation of IPSOL's in-house equipment should impress UK and international customers, as well as providing the flexibility for fast-turnaround testing. Khoury adds: "In terms of quality and value for money, MiniTec ticked all of the boxes. Our throughput rates are excellent and they also gave us excellent support after the test stands were delivered to iron-out a few minor snags that arose when we came to commission the equipment at our facility."

As an end-user, IPSOL used MiniTec's in-house design service for this particular application, but OEMs and System Integrators might prefer to use the MiniTec iCAD Assembler software suite themselves. Available free of charge, online or offline, the utility may be used in a standalone programming mode, requiring no CAD platform or specialist CAD knowledge, or in combination with the customer's preferred 2D or 3D CAD software. Features include straightforward menu selection and drag-and-drop manipulation of individual profiles, connectors and ancillary components. With the ability to assemble fully these elements on-screen to realise designs for anything from simple machine frames to complex automated assemblies, the software generates parts lists and BOMs for pricing and provides the designer with more than 50 data output format options in 2D and 3D, including AutoCAD, SolidWorks, ProEngineer, IGES and STEP4.

Contact MiniTec for more information about its Profile System.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 1 Telford Road

Houndmills Industrial Estate

RG21 6YU

UNITED KINGDOM

+44 (0)1256 365605