Posted to News on 22nd Mar 2023, 09:11

Modular linear guides for long distances assembled with ease

See Igus at MachineBuilding.Live, 4 October 2023, on stand 20

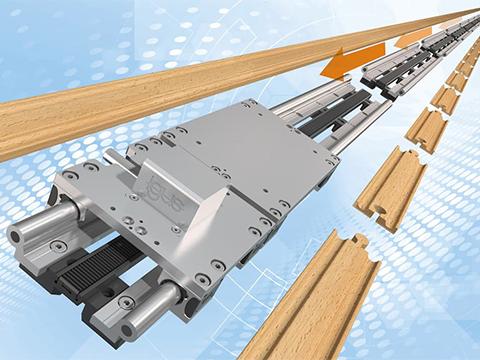

The drylin Endless Gear linear module (EGW) from Igus is a modular, lubricant-free linear guide with rack and pinion drive, which can be extended to any length due to the modular plug-in design, at low cost and very light weight.

Separate carriages can travel in different directions and at different speeds, unlike a belt drive. Being modular, the guide can be easily extended many times.

Linear axes with a toothed belt drive are suitable for many material handling and positioning tasks. But when the track is some 10 metres or more, drive belts are ineffective because they begin to sag and the elongation of the belt makes it difficult to drive it with accuracy.

A second problem is the lack of flexibility. Several carriages cannot travel at different speeds on the rails, not even in different directions.

“To offer greater options to all those who require long travel distances, we have developed drylin EGW – a modular linear guide with rack and pinion drive,” says Rob Dumayne, director of dry-tech products and bearings at Igus UK. “There are almost no limits for users in terms of travel length. You can add additional rails at any time, just like a model railway. It is designed as a modular system, supplied in two-metre-long sections, which also makes handling and transport much easier.”

In contrast to the toothed belt drive, it is also possible to have several carriages, each with its own electric motor, travel on a rail in different directions and at different speeds. With the drylin EGW modular system, users receive all the components from one source, from linear guides and carriages to chains and cables for energy supply. And they can be supplied ready for installation, including the motor and control.

The drylin EGW module consists of several components. The foundation is the WS-20 guide rail of the drylin W series, a rail made of hard anodised aluminium with a round profile, on which the slides are mounted and glide. A profile in the middle accommodates the polymer rack and pinion modules. The second component is the drive carriage, that sits on the rail with four plain bearings made of the high-performance plastic iglidur J200. An electric motor in the carriage provides movement, driving a gear wheel that engages the rack. The motor cable moves in an energy chain that runs parallel to the rail.

The third component is attached directly to the drive carriage: a towing carriage that can be used, for example, for a camera or on which handling units such as picking robots or sensors can be mounted.

By using a modular expandable linear guide, tasks such as testing or monitoring, for example, can be carried out with high and repeatable accuracy even over very long distances, ensuring greater quality and safety. For example, for safely inspecting train roofs, or workpieces in automotive production.

“In such applications, drylin EGW operates with much less vibration and more quietly than linear guides with classic recirculating ball systems,” says Dumayne. “In addition, thanks to the plastic-instead-of-metal principle, the weight of the guide system and thus the required drive energy and inertia is reduced.”

The linear guide drylin EGW is durable, proven by tests in Igus’ in-house laboratory. Engineers weighed down a carriage with a load of 200 N and moved it at a speed of 1 m/s on a stroke of 15,000mm. The result was that even after 45,000 cycles, there was no significant wear on the rails and plain bearing bushings. But if the linear guide does reach its wear limit at any point, users can easily replace the liners on the rail in just a few minutes and without dismantling the bearing housings.

Another advantage is that external lubrication is unnecessary because – as with all drylin products – solid lubricants are integrated into the high-performance plastic and are released over time, enabling low-friction dry running. And the maintenance needed is low.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>