Posted to News on 15th Dec 2020, 14:19

Money saving fully integrated proximity probes

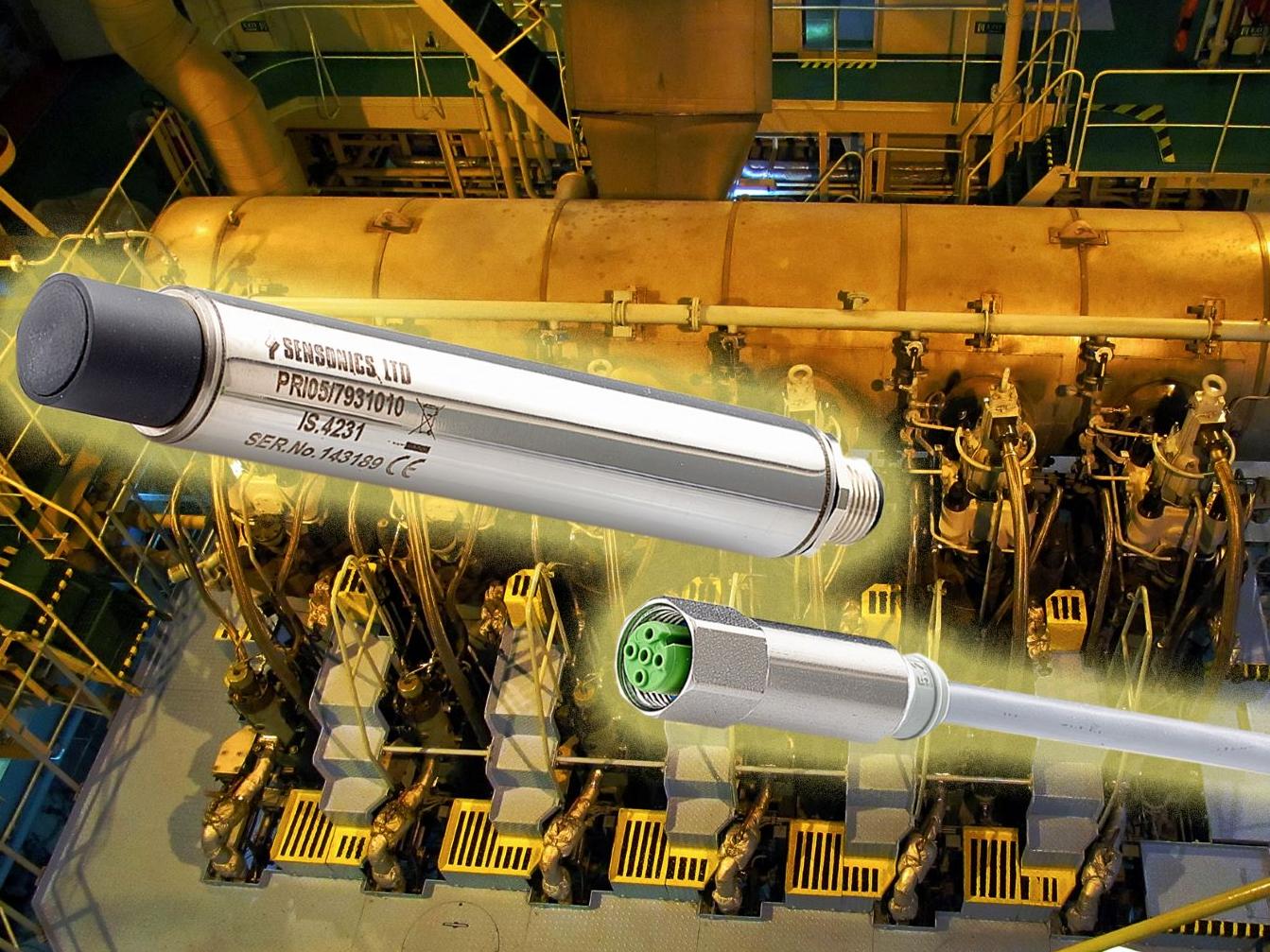

Condition monitoring specialists SENSONICS offers an extensive range of proximity sensors including its fully integrated PRI series, a single probe assembly solution featuring direct processed outputs which eliminate the need for a separate driver

The benefits are a more cost-efficient and easy-to-install solution says SENSONICS, as there is no driver, nor extension cable or associated driver housing: so capital and installation costs are kept to a minimum. The new PR l04 proximity probe system is a fully integrated probe with a driver and extension cable contained in the probe body. Utilising the eddy current principle, this combination forms a tuned circuit with the target material and variations in probe face-to-target distance are detected in this circuit by the driver, providing highly accurate vibration and relative positional measurements.

Sensonics says that is has continued to develop the PRI Series which has further extended the applications for proximity sensing, such as a rod drop option for engine monitoring. This option provides both a dynamic output and bearing wear indicator by measuring the bottom dead centre (BDC) position of the crank of a reciprocating internal combustion engine. The probe offers up to 4mm of BDC measurement range and auto-gapping LED’s are said to enable simple installation and set-up. The bearing wear is captured through a ‘sample and hold’ feature and is available on a 4-20mA current loop which avoids the need to use the engine speed (which may be variable) to capture the measurement, leading to a simplified system.

Further, recent design enhancements have resulted in improved performance for less demanding OEM applications where operating temperatures are below 120°Celsius such as industrial gearboxes, pumps, fans, blowers and hydro-generator applications. Meanwhile, the 180°Celsius rated standard XPR04 probes with separate drivers are said to be suitable for use on higher temperature machines such as steam turbines.

Higher reliability is assured thanks to having no external driver and tuned cable assemblies: coaxial connector interfaces can sometimes be a failure point on standard proximity probe systems. This is because they are susceptible to ingress of oil and dirt which can result in intermittent connection through either improper installation or mechanical stress. Also the PRI option has no cable length restrictions compared to standard probes which are typically restricted to 5m and 9m systems. With the PRI option there is no such restriction as they can drive long cable distances (>500m) to the connecting equipment. Available in a standard 10m cable for direct termination to the connecting equipment or a local junction box and by utilising the same 8mm diameter tip (as per API670 proximity probes) the PRI case body is available in the standard M10 and 3/8” UNF variants providing an easy retrofit option.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>