Posted to News on 23rd Nov 2021, 08:57

MONORAIL MR roller guideways launched

Four intrinsic improvements built into new series

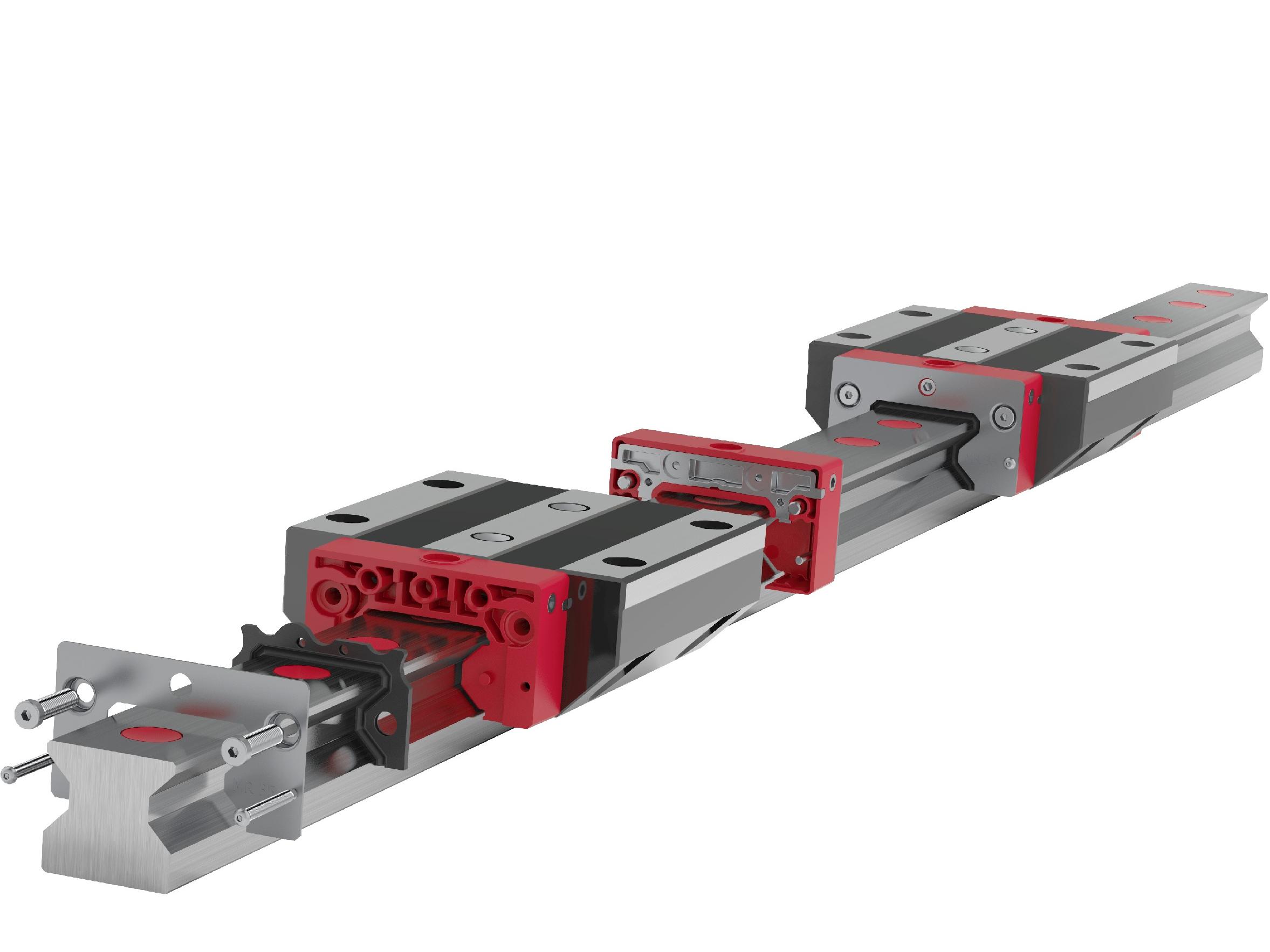

Schneeberger has introduced a new high-precision MONORAIL MR series of roller guideways. The MR 4S series has been designed with four intrinsic improvements, which, says Moore International, “will greatly provide extended life in more arduous applications”.

From its Poole warehouse, Moore International stocks the Schneeberger range of linear products. “The MONORAIL series has been providing the highest accuracy in small spaces for a number of years and for a number of linear movement applications,” states Mark Moore, of Moore International. “They are especially suitable for handling loads in the machine tool industry. Workpieces weighing up to 150 tonnes can be transported on machines equipped with the MONORAIL MR.”

He adds: “However, the MR 4S design has taken the performance capabilities of Schneeberger´s profiled guideways to a new level. They have focused on four major operational issues: lubrication, dirt resistance, shock resistance and serviceability”.

Method of lubrication

The method of lubrication can be specifically ascribed externally. The lubricators and front plate are seal-welded to form pressure-tight lubrications channels, which considerably improves lubrication when operating in idle.

Double-lipped wipers are attached to the carriages to prevent both the ingress of dirt, as well as the loss of lubricant. These double-lipped seals are fixed on the front plates, which are supported on both sides along the entire cross section. “This ensures reliable functionality, even under extreme loads,” says Moore International. “This new version can also be easy to maintain through the removal of the front steel plate and exchanging the cross wipers by simply pulling them up and over the rail in an axial direction.”

The front plate is made from stainless steel, but it also covers a plastic front plate. This provides extra protection against damage and contamination, as well as significantly improving shock resistance and the continuous running characteristics. To further improve reliability under heavy loads, even the heavily stressed carriage bodies have been optimised to counteract fatigue stress of notched parts that may occur.

Strength and flexibility factors

The MONORAIL MR series is available in sizes 25, 35, 45, 55 and 65, and the maximum length is 6000mm (per single rail). The largest size, MR100, is especially strong and suitable for loads of 150 tonnes. This specific size has a maximum part length of 3000mm. Greater travel distances can be achieved by linking rail segments together.

The body of the cartridges and rails on all MR sizes are made of high-quality hardened steel. Specially-shaped rollers are used as rolling elements, which contributes to extreme rigidness and the high dynamic and static load carrying capacity. In the standard version, the carriages can be accelerated by up to 50m/s during normal use and are designed for speeds of up to 3 m/s. Each size is available in a variety of accuracy classes – from G3 (standard), G2 and G1 to the high-precision class, G0.

Mark Moore further comments: “Schneeberger’s excellent technical expertise and customer service enables us to explore new opportunities in new sectors.”

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>

Unit 6 Factory Road

Upton Industrial Estate

BH16 5SL

UNITED KINGDOM

+ 44 (0) 1202 623 393