Posted to News on 24th Oct 2006, 19:55

Motors and drives cut annual energy bill by £40,000

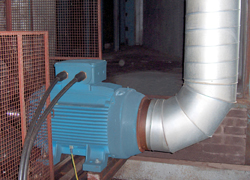

Two WEG 132kW EEF1 high-efficiency motors and CFW-09 Vectrue drives are providing Crisp Maltings of Portgordon, Scotland, with energy savings worth 40,000 per year on the operation of two, 2-metre diameter drying fans used in the production of high-quality malt.

Located on the Moray Firth coast, near to the mouth of the River Spey, the Crisp Portgordon Malting plant is well located to supply the malt distilleries on Speyside. With a capacity now in excess of 40,000 tonnes, following continuous upgrading and expansion, the plant has a justifiably excellent reputation for producing top-quality distilling malt.

Central to the production facilities at the Portgordon plant are large 2- metre diameter fans that dry the malt over continuous 36-hour periods. In 2005, problems were experienced with two of the 207kW DC motors that drive these fans. The major problem was that the DC machines were more-or-less obsolete, and Crisp Maltings was suffering from high maintenance and high running costs as a result.

Unable to get spares for the DC motors, Crisp decided to replace them, and put the project for replacement out to tender. One of the companies tendering was Grants of Dufftown, a local company with a long history of meeting the electrical and instrumentation needs of the maltings industry. In contrast to proposals from competitors, which basically proposed replacing the 207kW DC motors with 207kW AC machines, Grants decided to actually analyse the power output of the motors.

"We were not convinced that the DC motors were running at 207kW," says Stuart Duff of Grants. "I did some calculations and arrived at a figure of 140kW. We then put an energy analyser on one of the motors and came up with a figure of 142kW, which confirmed our earlier assumption."

Low-speed inefficiency

"The key to this reduction was that the motors were originally specified to run at 1750rpm, whereas they were actually operating at no more than 1500rpm, In addition to reduced power, this factor probably meant that the motors were running inefficiently, as DC machines are inefficient at low speeds."

Stuart Duff's in-depth analysis meant that 160kW AC motors and drives could be employed instead of 207kW units, providing a considerable cost saving on the project. This data was passed-on to the client and Grants was subsequently awarded a contract to provide a full turnkey motor and control package for the maltings fans. The package included two high-efficiency WEG EEF 1 machines from its W21 range, controlled by WEG CFW-09 Vectrue inverters, which were installed in Grant's enclosures. Both the drives and motors qualified for all relevant ECAs under the UK government's Climate Change Levy (CCL) scheme to limit carbon emissions.

The first DC motor was replaced with a WEG AC machine, and an analyser installed on the motor windings for a full 36-hour drying period. The result was a saving in energy of 48 per cent by the WEG EEF 1 motor, compared to the DC machine that it had replaced. On an annual basis, this saving equated to 20,000 per motor, a figure that has been achieved in the first year of operation. Moreover, the scale of the savings has meant a payback of just ten months for Crisp Maltings on what is a very large motor/control system.

"We are delighted with the outcome of this project," says Stuart Duff. "It highlights just what savings can be achieved by replacing old motor stock with new high-efficiency machines. With energy costs for industry at an all-time high, now is really the time for industry, generally, to invest in energy-saving motors and drives, and reap the ongoing cost-saving benefits that are a sure-fire way to improved profitability and competitiveness."

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>