Posted to News on 12th Feb 2014, 09:43

MTN/5000 condition monitoring system is easy to use

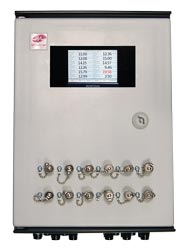

Monitran is launching the MTN/5000 condition monitoring system that is said to be easy to use, even by non-experts. This cost-effective and versatile system is equally suitable for new-build machines and for retrofitting to existing equipment. Unlike more expensive machine condition monitoring systems that perform detailed analyses, the Monitran MTN/5000 is designed as a first line of defence to help engineers decide when it might be necessary to take action or undertake further analysis.

Each MTN/5000 system can be specified with up to 12 channels and each features a 3.5 inch TFT touchscreen and an easy-to-navigate menu. Users can set data sampling rates (up to 1million/second), input ranges and resolution and alarm levels - on a channel-by-channel basis or across all channels.

The machine condition monitoring system is designed to work with Monitran's accelerometers and velocity sensors but it can also accommodate most other sensor types including those for measuring temperature, pressure, displacement and proximity. It can also accept a voltage or current as input, and raw signals are made available via BNC connectors on the front panel.

Remote condition monitoring

As standard the MTN/5000 has 12 digital I/O channels that can be used for multiple alarms or as a communication channel for integration with other systems such as SCADA packages. Also, as an optional extra, the system can be fitted with Modbus TCP/IP for networking purposes or to enable multiple MTN/5000s to operate together within a larger machine condition monitoring system or control system. By using an Ethernet connection on the MTN/5000 it is possible for data to be monitored remotely - for example, by a plant engineer in an office at the same premises or via a mobile device, or by a machine builder that could be located anywhere in the world with internet access.

If required, the alarm outputs can be used as inputs in a machine control system so that the machine can respond to an alarm by taking action such as operating at a reduced speed or stopping so as to prevent damage being caused to the machinery or product being processed.

Andy Anthony, Monitran's Managing Director, comments: "With the MTN/5000 we are providing engineers with a versatile tool that can provide a picture of the health of plant and equipment, raise alarms and indicate when further investigation may be warranted."

Visualising sensor outputs

Monitran developed the MTN/5000 in response to customers who were purchasing sensors but also asking how the sensors' outputs could be viewed without the cost and complexity of a comprehensive machine condition monitoring that performs detailed analysis on the sensor data. Monitran believes the MTN/5000 is likely to be unique in its cost-effective display-only approach that is combined with ease of use, a colour touchscreen display and remote monitoring capability. Customers can use the MTN/5000 to help decide when it might be necessary to take action or undertake further analysis.

If required, Monitran can provide full technical support, including advice on sensor selection and settings. Site visits can be arranged, and the company even offers an installation service.

Follow the link for more information about the MTN/5000 condition monitoring system and sensors from Monitran.

Want the latest machine building news straight to your inbox? Become a MachineBuilding member for free today >>